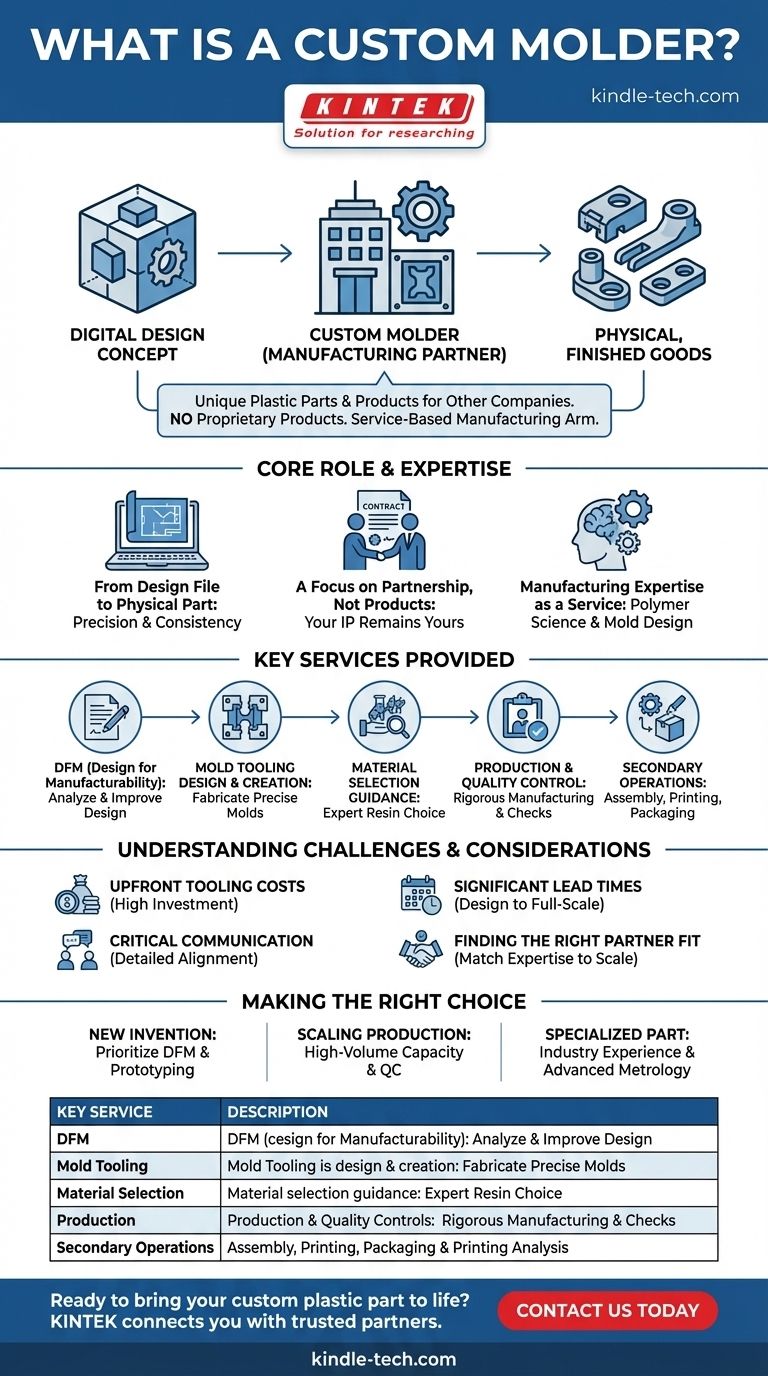

In the simplest terms, a custom molder is a manufacturing partner that produces unique plastic parts and products for other companies. They do not sell their own line of products; instead, they use their specialized equipment and expertise in processes like injection molding to transform a client's specific design concept into a physical, finished good.

A custom molder acts as the manufacturing arm for your specific vision. They translate your unique design into a tangible plastic component by managing the complex process of tooling, material selection, and mass production.

The Core Role of a Custom Molder

A common misconception is that a molder simply loads plastic into a machine and presses a button. The reality is they are highly skilled technical partners who bridge the gap between a digital design and a physical, mass-produced part.

From Design File to Physical Part

A custom molder takes a client's design, often a 3D CAD file, and develops a robust manufacturing process to create it. Their primary function is to turn that digital blueprint into thousands or even millions of identical physical parts with precision and consistency.

A Focus on Partnership, Not Products

Unlike a company that manufactures and sells its own plastic containers or toys, a custom molder works exclusively on a contract basis. Their business is built on providing a service, not on selling a proprietary product. Your design and intellectual property remain yours.

Manufacturing Expertise as a Service

Companies partner with custom molders to leverage expertise they don't have in-house. This includes deep knowledge of polymer science, mold design engineering, and the physics of high-volume manufacturing processes.

Key Services a Custom Molder Provides

Engaging with a custom molder involves much more than just the production run. A quality partner is involved at nearly every stage, from concept refinement to final assembly.

Design for Manufacturability (DFM)

This is a critical early-stage service. The molder's engineers analyze your part design and suggest modifications to improve its moldability, reduce costs, lower defect rates, and increase production speed. This step prevents costly problems before they start.

Mold Tooling Design and Creation

The most significant part of the process is creating the mold (or "tool"). This is a highly precise, durable piece of steel machined to form the cavity that the molten plastic is injected into. A custom molder manages the design, fabrication, and maintenance of this critical asset.

Material Selection Guidance

The choice of plastic resin impacts the part's strength, flexibility, temperature resistance, color, and cost. Custom molders provide expert guidance, helping you select the ideal polymer from thousands of available options to meet your product's specific requirements.

Production and Quality Control

Once the mold is approved, the molder runs the production process. This includes setting up the injection molding machines, managing cycle times, and implementing rigorous quality control measures to ensure every part meets the required specifications.

Secondary and Value-Added Operations

Many custom molders offer services beyond the molding machine. This can include assembly, sonic welding, pad printing, painting, special packaging, and supply chain management to deliver a more complete product.

Understanding the Challenges and Considerations

Working with a custom molder is a significant investment and partnership. Being aware of the potential challenges is key to a successful outcome.

The Upfront Investment: Tooling Costs

The mold is the most expensive and time-consuming single element of the process. The cost can range from thousands to hundreds of thousands of dollars, depending on the part's complexity, size, and required lifespan. This is a significant capital expenditure that must be planned for.

The Critical Need for Communication

The success of a project hinges on clear, detailed communication between your design team and the molder's engineering team. A misunderstanding of a critical dimension or performance requirement can lead to wasted time and money.

Lead Times are Significant

Custom molding is not an instant process. The timeline includes design refinement, mold fabrication, testing, and adjustments. It can take several weeks or months to go from a final design to the start of full-scale production.

Finding the Right Partner Fit

Not all molders are the same. Some specialize in high-volume production for the automotive industry, while others focus on low-volume, high-precision parts for medical devices. Choosing a molder whose equipment, expertise, and quality systems match your industry and project scale is crucial.

Making the Right Choice for Your Project

Selecting a manufacturing partner is a critical business decision. Your choice should align directly with the primary goal of your project.

- If your primary focus is bringing a new invention to market: Prioritize a molder with strong Design for Manufacturability (DFM) support and experience with prototyping.

- If your primary focus is scaling up production for an existing product: Look for a molder with proven high-volume capacity, robust quality control systems, and automation.

- If your primary focus is creating a highly specialized, high-tolerance part: You need a partner with documented experience in your specific industry (e.g., medical, aerospace) and advanced metrology capabilities.

Ultimately, choosing the right custom molder is about finding a true partner to bring your product to life reliably and efficiently.

Summary Table:

| Key Service | Description |

|---|---|

| Design for Manufacturability (DFM) | Engineers analyze your design to improve moldability and reduce costs. |

| Mold Tooling Creation | Manages the design and fabrication of the precise, durable mold. |

| Material Selection | Provides expert guidance to choose the ideal plastic resin for your needs. |

| Production & Quality Control | Runs the manufacturing process with rigorous quality checks. |

| Secondary Operations | Offers value-added services like assembly, printing, and packaging. |

Ready to bring your custom plastic part to life?

Choosing the right manufacturing partner is critical to your product's success. KINTEK specializes in precision lab equipment and consumables, and we understand the importance of reliable, high-quality components. Our network includes trusted custom molders who can help you navigate the entire process—from design refinement to mass production.

Let us connect you with a partner who can:

- Optimize your design for manufacturability and cost-efficiency.

- Guide material selection for optimal performance.

- Ensure consistent quality with rigorous production controls.

Contact us today to discuss your project needs and find the perfect manufacturing solution!

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Isostatic Molding Pressing Molds for Lab

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What are the advantages of using bi-directional pressing graphite molds? Achieve Superior Density and Precision

- What is the difference between a 2 plate and a 3 plate mold? Choose the Right Injection Mold for Your Project

- What is the cheapest molding process? Find the Right Process for Your Budget and Volume

- Why is a high-strength pressure die required for NCM811 electrode cold pressing? Ensure Superior Battery Density

- Why is it necessary to use pressure-maintaining dies or fixtures? Ensure Solid-State Battery Interface Stability

- What role does a rigid mold play in hot pressing amorphous alloys? Ensure Precision in Composite Assembly

- How to keep ceramic clay from sticking to mold? Master Moisture Control for a Perfect Release