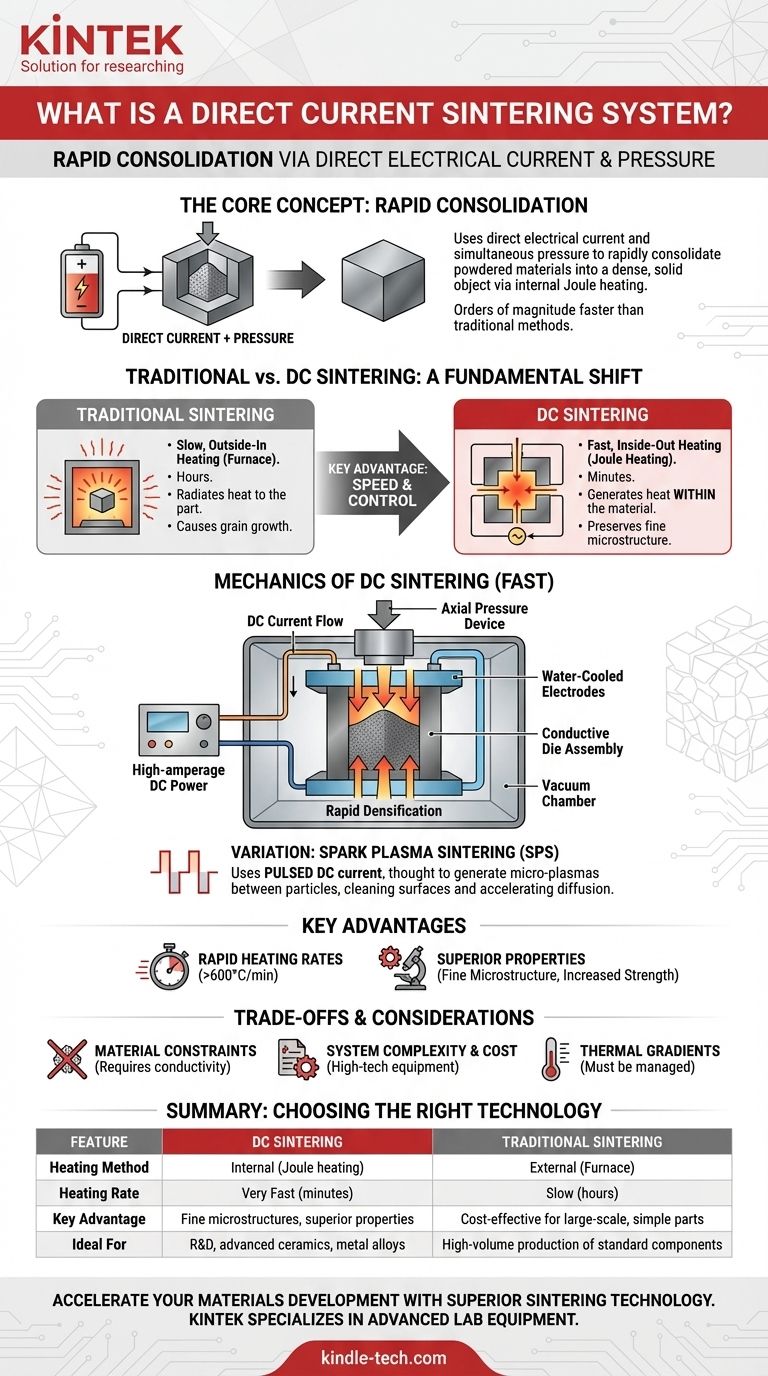

At its core, a direct current (DC) sintering system is a manufacturing technology that uses direct electrical current and simultaneous mechanical pressure to rapidly consolidate powdered materials into a dense, solid object. By passing a continuous current directly through a conductive die holding the powder, the system generates intense heat internally via Joule heating, allowing for processing times that are orders of magnitude faster than traditional methods.

While traditional sintering slowly heats materials from the outside-in using a furnace, DC sintering heats them from the inside-out using electricity. This fundamental shift is the key to its primary advantages: unprecedented speed and enhanced control over the final material's properties.

What is Sintering? A Foundational Concept

To understand DC sintering, one must first understand sintering itself. It is a cornerstone process in materials science and manufacturing.

The Goal: Fusing Powders Without Melting

Sintering is the process of compacting and forming a solid mass of material by heat and pressure. Crucially, this occurs without melting the material to the point of liquefaction.

The applied heat and pressure cause atoms in the material's particles to diffuse across their boundaries, fusing the particles together and gradually eliminating the porous spaces between them.

Traditional Sintering Methods

Historically, this is done by placing a pre-compacted part into a high-temperature furnace for many hours. The heat slowly radiates into the part, driving the diffusion process. This method is used for everything from ceramics to powder metallurgy.

The Mechanics of Direct Current Sintering

DC sintering, often called Field-Assisted Sintering Technology (FAST), fundamentally changes how the required heat is delivered.

The Core Principle: Joule Heating

The defining mechanism is Joule heating. A powerful direct current is passed through the graphite die that contains the powdered material.

Because the die has electrical resistance, the flow of current generates immense heat—much like the coil on an electric stove. This heat is generated within the tooling assembly itself, allowing for extremely rapid and direct heating of the sample.

Key System Components

A typical DC sintering system is more complex than a simple furnace. It integrates several key parts:

- An axial pressure device to apply mechanical force.

- Water-cooled electrodes to deliver high current to the die.

- A conductive die assembly, usually made of graphite, to hold the powder.

- A DC power supply capable of delivering very high amperage.

- A vacuum chamber and atmosphere control system to prevent oxidation.

An Important Variation: Spark Plasma Sintering (SPS)

While some systems use a continuous DC current, a more advanced and common variant is Spark Plasma Sintering (SPS).

SPS uses a pulsed DC current. This pulsed application is thought to generate micro-plasmas between the powder particles, which helps to clean particle surfaces and further accelerate the diffusion and densification process.

The Key Advantage: Speed and Control

The shift from external furnace heating to internal Joule heating provides significant benefits that drive the adoption of DC sintering.

Direct vs. Indirect Heating

A conventional furnace must heat an entire chamber and then slowly transfer that heat to the material via conduction and radiation. This is inefficient and can take many hours.

DC sintering heats the die and powder directly, reaching temperatures over 1500°C in just minutes. This allows for extremely rapid heating rates, often exceeding 600°C per minute.

Impact on Material Properties

This rapid processing cycle isn't just about saving time. By minimizing the time a material spends at high temperature, DC sintering can prevent unwanted grain growth.

This results in materials with a finer microstructure, which often translates to superior mechanical properties like increased strength and hardness.

Understanding the Trade-offs

Despite its advantages, DC sintering is not a universal solution. It comes with specific constraints and considerations.

Material and Geometry Constraints

The primary requirement is electrical conductivity. The process relies on current flowing through the die assembly, and in many cases, through the powder itself. This makes it challenging to process highly insulating materials without special techniques.

System Complexity and Cost

The equipment—requiring high-current power supplies, vacuum systems, and robust pressing frames—is significantly more complex and expensive than a standard industrial furnace.

Thermal Gradients

The extremely rapid heating rates can sometimes create temperature differences, or thermal gradients, within the sample. Managing these gradients is critical to achieving a uniform, homogenous final part, especially for larger components.

Is DC Sintering Right for Your Application?

Choosing the right sintering technology depends entirely on your end goal, material, and production scale.

- If your primary focus is rapid material development or prototyping: DC sintering is an unparalleled tool, allowing you to cycle through multiple experiments in the time it would take to run a single furnace cycle.

- If your primary focus is creating advanced materials with fine microstructures: The speed of DC sintering is essential for preserving nano-scale features and achieving superior properties in high-performance ceramics and metal alloys.

- If your primary focus is large-scale production of simple, non-critical parts: Traditional press-and-sinter or furnace-based methods will likely remain the more cost-effective choice.

Ultimately, understanding the fundamental principle of direct Joule heating is the key to recognizing where this powerful technology can be best applied.

Summary Table:

| Feature | DC Sintering | Traditional Sintering |

|---|---|---|

| Heating Method | Internal (Joule heating) | External (Furnace) |

| Heating Rate | Very Fast (minutes) | Slow (hours) |

| Key Advantage | Fine microstructures, superior properties | Cost-effective for large-scale, simple parts |

| Ideal For | R&D, advanced ceramics, metal alloys | High-volume production of standard components |

Ready to accelerate your materials development with superior sintering technology?

KINTEK specializes in advanced lab equipment, including sintering systems. Our expertise can help you achieve rapid prototyping and create materials with enhanced properties. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts