At its core, a fluidized bed reactor for pyrolysis uses a flow of hot gas to make a bed of solid particles, like sand, behave like a boiling liquid. This "fluidized" bed then rapidly and uniformly heats a feedstock material, such as biomass, in an oxygen-free environment to break it down into valuable products like bio-oil and syngas. The design excels at efficient heat transfer and precise temperature control.

The fundamental advantage of a fluidized bed reactor is its ability to achieve exceptionally high rates of heat transfer. This rapid, uniform heating is critical for maximizing the yield of desired liquid products (bio-oil) and minimizing the production of less valuable char.

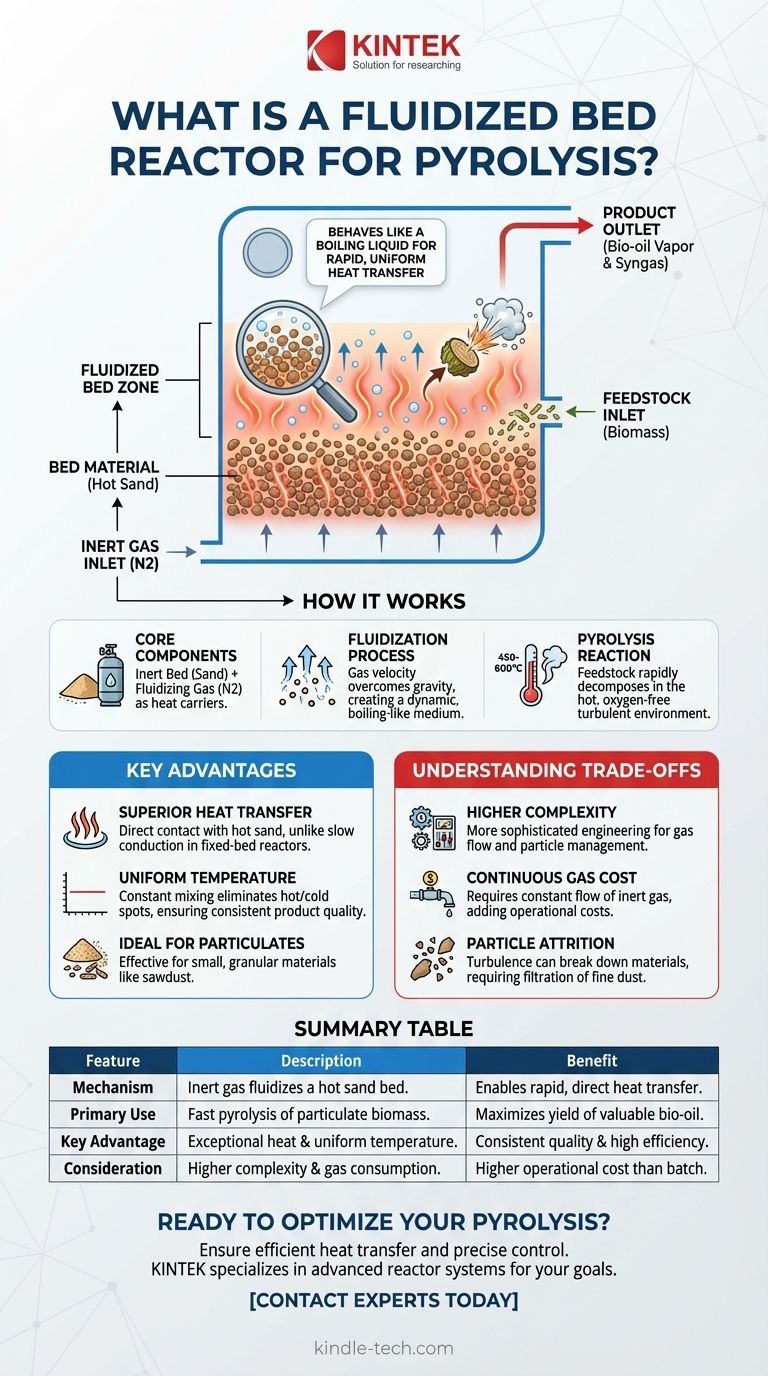

How a Fluidized Bed Reactor Works

A fluidized bed reactor's effectiveness comes from the unique physical state it creates. It transforms a static bed of solid particles into a dynamic, fluid-like medium for the chemical reaction.

The Core Components

The system is built around two key elements: the bed material and the fluidizing gas.

The bed material is typically an inert, thermally stable solid like sand. Its purpose is to act as a heat carrier, storing thermal energy and transferring it directly to the feedstock.

An inert fluidizing gas, most often nitrogen, is continuously forced up through the bed material from below. This gas prevents unwanted combustion and provides the mechanical force for fluidization.

The Fluidization Process

As the gas flows upward through the sand, it exerts a drag force on the particles. When the gas velocity is high enough, this force counteracts gravity, causing the particles to become suspended in the gas stream.

The entire mixture of gas and solid particles then begins to bubble and churn, behaving exactly like a boiling fluid. This creates a highly turbulent environment with incredibly efficient mixing.

The Pyrolysis Reaction

Once the bed is fluidized and heated to the target pyrolysis temperature (typically 450-600°C), the feedstock (e.g., woody biomass particles) is introduced.

The moment the feedstock enters the reactor, it is engulfed by the hot, turbulent sand. This results in near-instantaneous heat transfer, causing the material to rapidly decompose into vapor and gas products, which are then carried out of the reactor for collection and condensation.

Key Advantages Over Other Designs

The unique mechanics of a fluidized bed offer distinct advantages, particularly when compared to simpler designs like fixed-bed reactors.

Superior Heat Transfer

In a fixed-bed reactor, heat must slowly conduct from the reactor walls into a static pile of feedstock. A fluidized bed circumvents this by using the entire mass of hot sand to directly heat the feedstock from all sides simultaneously, dramatically increasing the rate of thermal decomposition.

Uniform Temperature Control

The constant, vigorous mixing of the fluidized bed eliminates hot or cold spots within the reactor. This ensures that every particle of feedstock experiences the same temperature profile, leading to a more consistent and predictable product quality.

Ideal for Particulate Feedstocks

The design is exceptionally effective for processing small, granular materials like sawdust, agricultural residues, or shredded plastics. The fluidizing action easily accommodates and processes these fine particles, which would be difficult to handle in other systems.

Understanding the Trade-offs

While powerful, the fluidized bed design is not without its complexities and limitations. It represents a trade-off between performance and operational simplicity.

Higher Design Complexity

Compared to a simple fixed-bed system, a fluidized bed reactor requires more sophisticated engineering. Managing gas flow, preventing particle elutriation (escape of fine particles), and handling the feedstock injection requires a more complex setup.

Continuous Gas Consumption

The process relies on a constant flow of inert gas, typically nitrogen. This represents a continuous operational cost that simpler, non-fluidized systems do not have.

Particle Attrition

The turbulent environment can cause the bed material and even the feedstock particles to break down over time, creating fine dust. This dust must be filtered from the product stream, adding another layer to the process.

Making the Right Choice for Your Goal

The decision to use a fluidized bed reactor depends entirely on the feedstock you are processing and the primary product you wish to obtain.

- If your primary focus is maximizing bio-oil yield from fine particles (like sawdust): The fluidized bed reactor's rapid and uniform heating is the ideal choice for fast pyrolysis.

- If your primary focus is operational simplicity for a low-throughput, batch process: A fixed-bed reactor may be a more practical and cost-effective solution, despite its lower efficiency.

- If your primary focus is processing very large, non-uniform biomass (like whole wood chips): Other designs, such as an ablative reactor that uses direct contact with a hot surface, may be more mechanically suitable.

Understanding these core principles allows you to select the precise technology that aligns with your specific material conversion goals.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Mechanism | Inert gas fluidizes a hot sand bed, creating a boiling liquid-like state. | Enables rapid, direct heat transfer to feedstock. |

| Primary Use | Fast pyrolysis of particulate biomass (e.g., sawdust). | Maximizes yield of valuable liquid bio-oil. |

| Key Advantage | Exceptional heat transfer and uniform temperature. | Consistent product quality and high efficiency. |

| Consideration | Higher complexity and continuous gas consumption. | Higher operational cost than simpler batch reactors. |

Ready to optimize your pyrolysis process for maximum bio-oil yield?

The principles of efficient heat transfer and temperature control are critical for successful biomass conversion. At KINTEK, we specialize in advanced laboratory equipment, including reactor systems designed for precise thermal processing.

Whether you are developing a new pyrolysis process or scaling up your research, our expertise can help you select the right technology to meet your specific conversion goals.

Contact our experts today to discuss how KINTEK's solutions can enhance your lab's capabilities in biomass and energy research.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the pressure in a batch reactor? A Guide to Dynamic Control and Safety

- What role does a high-pressure hydrothermal reactor play in the production of biochar? Enhance Biochar Quality Now

- Why are high-pressure stainless steel reactors required for the subcritical water hydrolysis of corn cob biomass?

- Why use a gas-tight reactor for ZVI electron efficiency? Master Mass Balance in Organic Halide Reduction

- What are the design advantages of a stainless steel fixed-bed reactor? Optimize Biomass Catalytic Pyrolysis Experiments

- What are the technical advantages of high-pressure reactor extraction vs Soxhlet? Boost Polymer Analysis Precision

- Why use a stirred high-pressure autoclave for plastic pyrolysis? Maximize Yields with Advanced Mass Transfer

- How do stirred reactors improve glycerin purification? Maximize Mass Transfer with KINTEK Solvent Extraction Systems