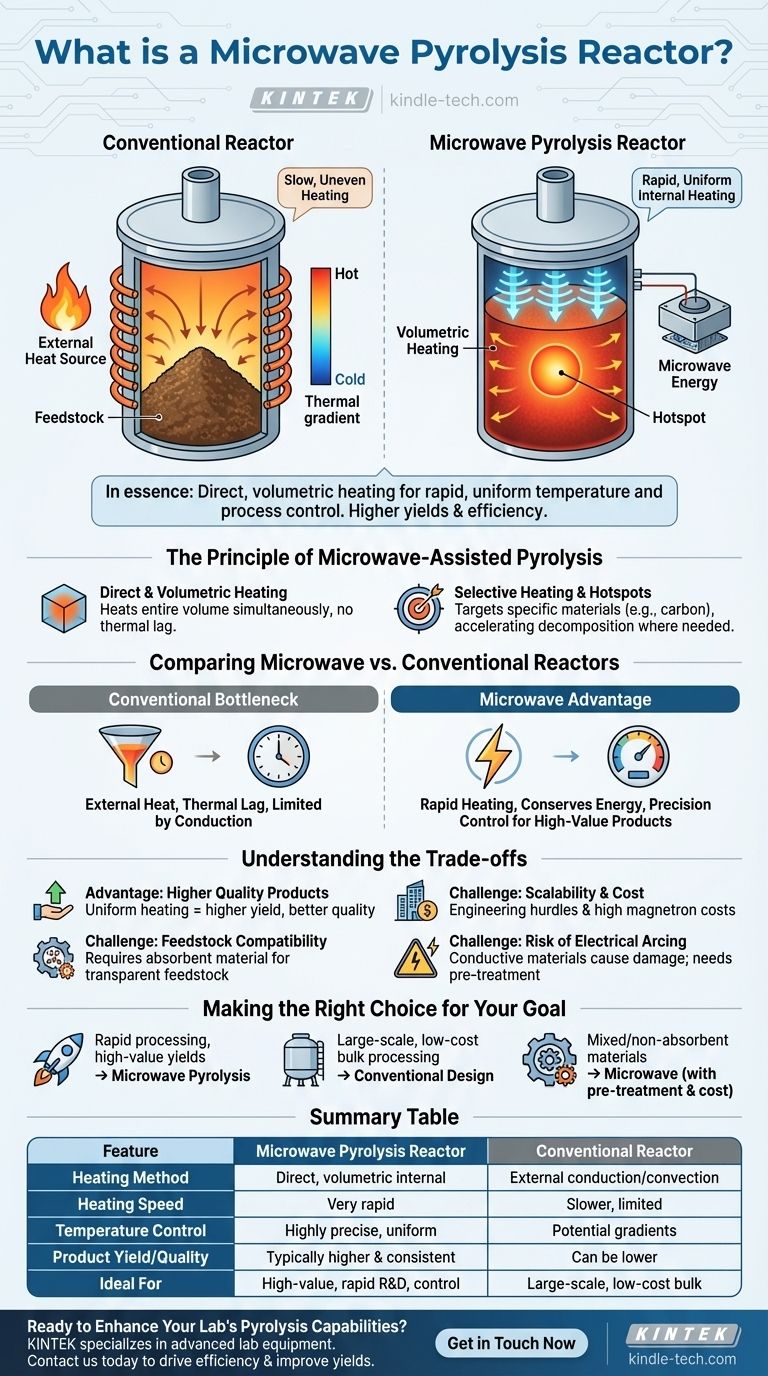

In essence, a microwave pyrolysis reactor is a specialized system that uses microwave energy, rather than a conventional external heat source, to thermally decompose materials in an oxygen-free environment. This method heats the feedstock directly from the inside out, leading to fundamentally different process dynamics compared to traditional reactors that heat from the outside in.

The core advantage of microwave pyrolysis lies in its mechanism of direct, volumetric heating. This provides rapid, uniform temperature distribution and greater process control, often resulting in higher yields of desired products and improved energy efficiency compared to conventional methods.

The Principle of Microwave-Assisted Pyrolysis

To understand a microwave reactor, one must first grasp how it fundamentally differs from the reactors that rely on conduction and convection.

Direct and Volumetric Heating

Conventional reactors, such as the fixed-bed or tubular types, heat the outer walls of a vessel. This thermal energy must then slowly transfer through the feedstock material, a process that is often slow and uneven.

Microwave pyrolysis bypasses this limitation entirely. It works by converting electromagnetic energy directly into thermal energy inside the material itself, heating the entire volume simultaneously.

Selective Heating and Hotspots

Microwaves do not heat all materials equally. They selectively and efficiently heat substances with high dielectric properties, such as carbon.

This unique characteristic allows for the creation of targeted "hotspots" within the feedstock. This can dramatically accelerate the decomposition process precisely where it is needed, avoiding unnecessary heating of the entire reactor chamber.

Comparing Microwave vs. Conventional Reactors

The operational differences between microwave and conventional pyrolysis lead to significant performance distinctions.

The Conventional Heat Transfer Bottleneck

Reactors like the circulating fluidized-bed are designed to improve heat distribution, but they still rely on an external energy source and the physical transfer of heat via a medium. This introduces thermal lag and potential temperature gradients.

The efficiency of these systems is fundamentally limited by the rate at which heat can physically conduct or convect into the center of each particle of feedstock.

The Microwave Advantage: Speed and Precision

By heating internally, microwave reactors achieve exceptionally rapid heating rates. This dramatically reduces processing time and allows for quick startup and shutdown cycles, conserving energy.

This precision enables fine-tuned control over the reaction, making it possible to steer the process toward producing specific high-value products like bio-oil, syngas, or char.

Understanding the Trade-offs

While powerful, microwave pyrolysis is not a universal solution. Its unique mechanism presents both distinct advantages and specific challenges.

Advantage: Higher Quality Products

The uniform heating provided by microwaves minimizes unwanted secondary reactions that often occur in the uneven temperature zones of conventional reactors. This typically results in a higher yield and better quality of the desired end products.

Challenge: Feedstock Compatibility

Materials that are transparent to microwaves (low dielectric loss), such as dry biomass or certain plastics, do not heat effectively on their own.

These applications require mixing the feedstock with a microwave-absorbent material, like silicon carbide or biochar, to initiate and sustain the pyrolysis process.

Challenge: Scalability and Cost

Designing and building large-scale industrial microwave reactors presents significant engineering hurdles. Ensuring a uniform microwave field in a large cavity is complex, and the high cost of industrial magnetrons can make it less economically viable than simpler, large-scale systems like tubular or batch reactors.

Challenge: Risk of Electrical Arcing

If the feedstock contains conductive materials, such as metals from a municipal waste stream, there is a serious risk of electrical arcing. This phenomenon can damage the equipment and create safety hazards, often necessitating thorough pre-treatment of the feedstock.

Making the Right Choice for Your Goal

Selecting the appropriate reactor technology depends entirely on your specific objectives, feedstock, and scale.

- If your primary focus is rapid processing and high-value product yields: Microwave pyrolysis offers unparalleled speed, precision, and control, making it an excellent choice for specialized applications.

- If your primary focus is large-scale, low-cost bulk processing of a uniform feedstock: A proven conventional design like a tubular or circulating fluidized-bed reactor is likely a more pragmatic and economical solution.

- If your primary focus is processing mixed or non-absorbent materials: You must account for the additional cost and complexity of using microwave absorbers and implementing rigorous feedstock pre-treatment.

Ultimately, choosing microwave pyrolysis is a strategic decision that prioritizes process control and efficiency over the raw simplicity of conventional heating.

Summary Table:

| Feature | Microwave Pyrolysis Reactor | Conventional Reactor (e.g., Tubular, Fluidized-Bed) |

|---|---|---|

| Heating Method | Direct, volumetric internal heating | External heating via conduction/convection |

| Heating Speed | Very rapid | Slower, limited by heat transfer |

| Temperature Control | Highly precise, uniform | Potential for gradients and hotspots |

| Product Yield/Quality | Typically higher and more consistent | Can be lower due to secondary reactions |

| Ideal For | High-value products, rapid R&D, process control | Large-scale, low-cost bulk processing |

Ready to Enhance Your Lab's Pyrolysis Capabilities?

KINTEK specializes in advanced lab equipment, including pyrolysis systems. Whether you're researching bio-oils, syngas, or char production, the right reactor is key to your success. Our experts can help you determine if a microwave pyrolysis reactor is the ideal solution for your specific feedstock and goals.

Contact us today to discuss your application and discover how KINTEK's solutions can drive efficiency and improve yields in your laboratory.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- Which of the following are methods used to deposit thin films? A Guide to PVD, CVD & More

- How are diamonds used for industrial purposes? Unlock Extreme Performance with Diamond Tools

- What causes sputtering when accelerating? Fix Engine Hesitation and Misfires

- What is the plasma sintering method? Unlock Rapid, High-Density Material Fabrication

- What is the process of sintering reaction? Transform Powder into Dense, High-Performance Parts

- What is the temperature at the bottom of the blast furnace? Unlocking the Heart of Iron Production

- Does pyrolysis affect the environment? A Dual-Sided Look at Waste Reduction and Pollution Risks

- How does heat treatment affect material selection? Choose the Right Alloy for Your Desired Properties