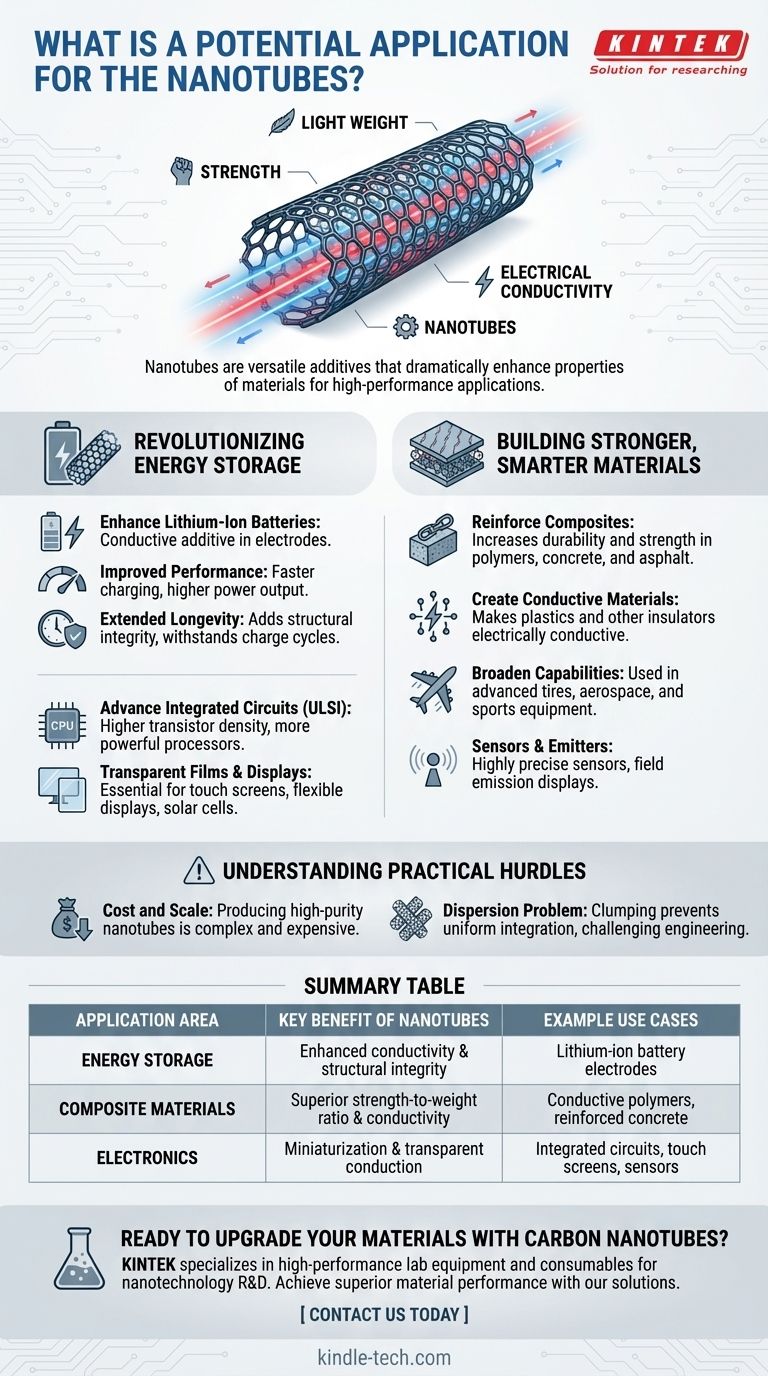

In short, nanotubes are versatile additives used to dramatically enhance the properties of other materials. Their most critical applications are in high-performance lithium-ion batteries, advanced composite materials like conductive polymers and reinforced concrete, and next-generation nanoelectronics.

The core value of nanotubes lies in their extraordinary combination of strength, light weight, and electrical conductivity. By integrating them into existing products, we can create materials that are fundamentally stronger, more efficient, and more capable than their conventional counterparts.

Revolutionizing Energy Storage

The most significant commercial use of carbon nanotubes today is as a conductive additive in the electrodes of lithium-ion batteries.

Enhancing Cathode and Anode Performance

Nanotubes create a highly efficient, three-dimensional conductive network within the battery's cathode and anode materials. This network allows electrons to move more freely and quickly.

This improved electrical conductivity translates directly to faster charging and discharging rates and higher power output for the battery.

Improving Battery Longevity

The nanotube network also adds structural integrity to the electrode, helping it withstand the physical expansion and contraction that occurs during charge cycles. This reinforcement leads to a longer and more reliable battery lifespan.

Building Stronger, Smarter Materials

Nanotubes act as a powerful reinforcing agent, creating a new class of materials known as composites with superior properties.

Reinforcing Polymers and Concrete

When mixed into materials like polymers, concrete, or asphalt, the immense strength-to-weight ratio of nanotubes significantly increases the final product's durability and strength without adding significant weight.

Creating Conductive Composites

By adding a small percentage of nanotubes, traditionally insulating materials like plastics can be made electrically conductive. This is crucial for applications requiring static dissipation or integrated electronic functionality.

Broadening Material Capabilities

This same principle applies to a wide range of other composites, including advanced tires, lighter and stronger metal alloys, and fiber-reinforced polymers used in aerospace and high-performance sports equipment.

Enabling Next-Generation Electronics

The unique properties of nanotubes make them a key component for pushing beyond the limits of traditional microelectronics.

Advancing Integrated Circuits

Nanotubes can be used to create components for ultra-large-scale integrated circuits (ULSI). Their minuscule size allows for a much higher density of transistors, enabling more powerful and efficient processors.

Powering Transparent Films and Displays

Nanotubes can be deposited on glass or flexible substrates to create transparent conductive films. These are essential for developing touch screens, flexible displays, and advanced solar cells.

Use in Sensors and Emitters

The high surface area and sensitivity of nanotubes make them ideal for creating highly precise chemical and biological sensors. They are also used in field emission displays due to their efficiency at emitting electrons.

Understanding the Practical Hurdles

While the potential of nanotubes is immense, their widespread adoption faces a few key technical and economic challenges.

The Challenge of Cost and Scale

Producing high-purity, high-quality nanotubes remains a complex and relatively expensive process. Lowering manufacturing costs is critical for their use in mass-market applications.

The Dispersion Problem

Nanotubes have a natural tendency to clump together, which can prevent them from integrating effectively into a host material. Achieving a uniform, even dispersion is a major engineering challenge that determines the final performance of the composite.

Aligning Applications with Core Goals

The right application for nanotubes depends entirely on the problem you are trying to solve.

- If your primary focus is energy efficiency and storage: Leverage nanotubes as a conductive additive in battery electrodes to boost power and lifespan.

- If your primary focus is mechanical performance: Use nanotubes as a reinforcing agent in composites to create materials that are stronger, more durable, and lighter.

- If your primary focus is advanced electronics: Explore nanotubes for creating transparent conductive films, next-generation transistors, and highly sensitive sensors.

Ultimately, the potential of nanotubes lies in their ability to fundamentally upgrade the performance of the materials we rely on every day.

Summary Table:

| Application Area | Key Benefit of Nanotubes | Example Use Cases |

|---|---|---|

| Energy Storage | Enhanced conductivity & structural integrity | Lithium-ion battery electrodes |

| Composite Materials | Superior strength-to-weight ratio & conductivity | Conductive polymers, reinforced concrete |

| Electronics | Miniaturization & transparent conduction | Integrated circuits, touch screens, sensors |

Ready to upgrade your materials with carbon nanotubes?

KINTEK specializes in high-performance lab equipment and consumables for nanotechnology research and development. Whether you are developing next-generation batteries, stronger composites, or advanced electronics, our solutions can help you achieve superior material performance.

Contact us today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- Multi-zone Laboratory Tube Furnace

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How does a multi-heating zone horizontal tube furnace benefit alloy testing? Maximize Thermal Uniformity and Throughput

- What are the advantages of using multi-stage split tube furnaces for heating methane pyrolysis reactors? Boost Efficiency

- What are the advantages of using a Multi-zone Tube Furnace? Enhanced Thermal Uniformity for Diffusion Research

- What is a three zone furnace? Achieve Superior Thermal Control and Uniformity

- What is the temperature resistance of a ceramic tube? It Depends on the Material—Find the Right Fit