Bio-oil production via pyrolysis is a thermochemical conversion process that transforms solid biomass into a liquid fuel. It involves rapidly heating organic materials like wood or agricultural waste to high temperatures in an environment with little to no oxygen, breaking them down into vapors that are then cooled and condensed into a dark, viscous liquid known as bio-oil or pyrolysis oil.

Pyrolysis offers a direct path to liquefy solid biomass, making it easier to transport and store. However, the resulting raw bio-oil is chemically unstable and has a lower energy content than petroleum, requiring significant upgrading before it can be a widespread substitute for fossil fuels.

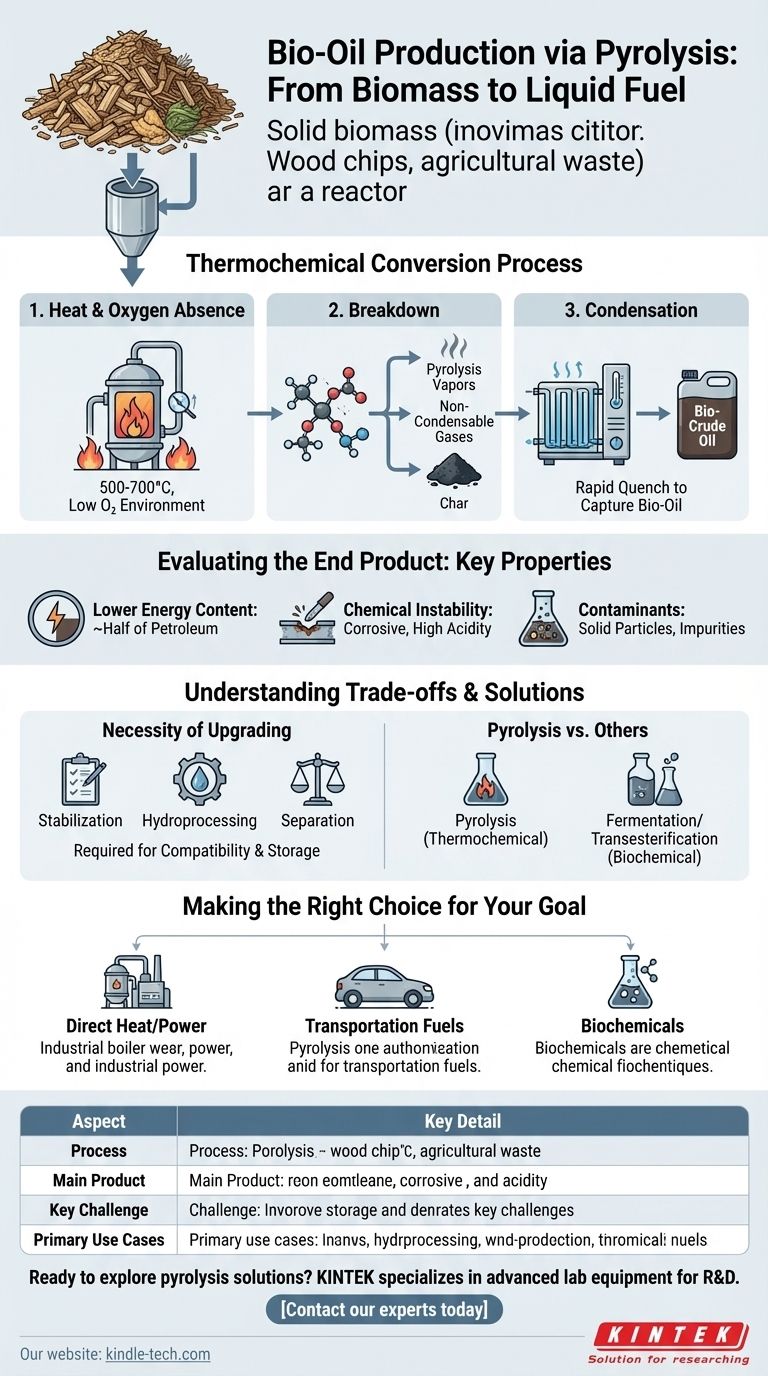

The Pyrolysis Process Deconstructed

Pyrolysis fundamentally "cooks" biomass to break its complex structure into simpler, valuable components. The process is carefully controlled to maximize the liquid yield.

The Role of Heat and Oxygen Absence

The core of the process is heating biomass to high temperatures, typically between 500°C and 700°C.

This is done in an oxygen-free or low-oxygen atmosphere. The absence of oxygen is critical because it prevents the biomass from combusting (burning) and instead forces it to thermally decompose into other substances.

From Solid to Vapor, Gas, and Char

This intense, oxygen-deprived heat breaks down the organic matter into three primary outputs:

- Pyrolysis Vapors: A hot mixture of aerosols and gaseous organic compounds. This is the primary precursor to bio-oil.

- Non-Condensable Gases: Light gases (like CO, CO2, H2, CH4) that do not turn into liquid upon cooling.

- Char: A solid, carbon-rich residue similar to charcoal.

Condensation: Capturing the Bio-Oil

After the solid char is separated, the hot pyrolysis vapors are rapidly cooled, or "quenched." This condensation process converts the vapors into a liquid, which is the final bio-crude oil.

Evaluating the End Product: The Properties of Bio-Oil

The raw bio-oil produced from pyrolysis is not a direct replacement for conventional crude oil. Its unique chemical properties present significant challenges.

Energy Content: A Key Limitation

The heating value of bio-oil is a primary concern. By weight, it contains only about half the energy of petroleum-based heating oil, meaning you need roughly twice as much to produce the same amount of heat.

Chemical Instability: Acidity and Corrosion

Bio-oil is highly acidic and contains a significant amount of water. This makes it extremely corrosive to common metals like steel and aluminum, complicating storage, transport, and use in standard engines or burners.

The Problem of Contaminants

The liquid can also contain small solid particles (char) and other impurities from the original biomass. These contaminants must be filtered out to prevent blockages and damage to equipment.

Understanding the Trade-offs and Solutions

While pyrolysis is an effective liquefaction technology, the resulting bio-oil must be improved to compete with fossil fuels. This introduces critical trade-offs between cost and usability.

The Necessity of Upgrading

To overcome its inherent flaws, raw bio-oil must undergo stabilization and upgrading.

Processes like hydroprocessing (treating with hydrogen at high pressure), separation, and derivatization can remove corrosive compounds, increase energy density, and improve chemical stability. This makes the oil more compatible with existing fuel infrastructure.

Pyrolysis vs. Other Biofuel Methods

It's important to distinguish pyrolysis from other biofuel production methods.

Pyrolysis is a thermochemical process that uses heat. In contrast, processes like fermentation (to produce ethanol) and transesterification (to produce biodiesel) are biochemical processes that use microorganisms or enzymes. Each pathway is suited for different types of biomass and produces a distinct type of fuel.

Making the Right Choice for Your Goal

The viability of bio-oil depends entirely on its intended application and your willingness to invest in post-processing.

- If your primary focus is direct heat or power generation: Bio-oil can be burned in specialized industrial boilers or furnaces designed to handle its corrosive nature and lower energy content.

- If your primary focus is producing transportation fuels: Upgrading is non-negotiable. The raw oil must be processed to create a stable, high-energy-density fuel compatible with conventional engines.

- If your primary focus is creating biochemicals: Bio-oil can serve as a feedstock for refineries that extract valuable chemicals, but this requires advanced separation and purification technologies.

Ultimately, pyrolysis is a powerful tool for converting diverse, low-value biomass into a more valuable and versatile liquid energy carrier.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Heating biomass (500-700°C) without oxygen to produce liquid bio-oil. |

| Main Product | Bio-oil (pyrolysis oil), a dark, viscous liquid. |

| Key Challenge | Raw bio-oil is unstable, corrosive, and has low energy content. |

| Primary Use Cases | Heat/power generation (direct use) or upgraded for transport fuels/chemicals. |

Ready to explore pyrolysis solutions for your biomass conversion needs?

KINTEK specializes in advanced laboratory equipment for bio-oil research and development. Whether you are developing new pyrolysis processes, analyzing bio-oil properties, or upgrading fuel quality, our reactors, analyzers, and consumables provide the precision and reliability you need.

Contact our experts today to discuss how our solutions can accelerate your biofuel projects and help you turn biomass into valuable energy.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout