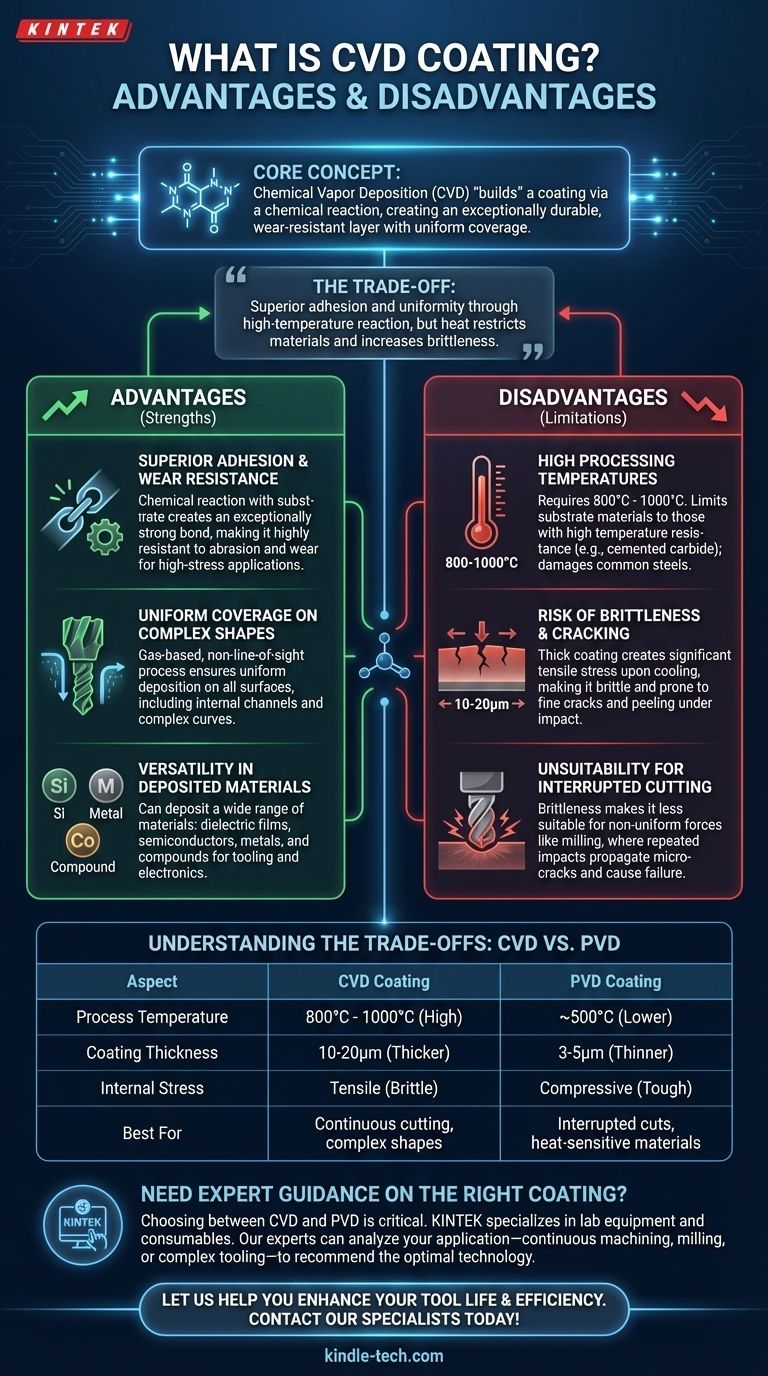

At its core, Chemical Vapor Deposition (CVD) is a process of "building" a coating directly onto a surface through a chemical reaction. Its primary advantage is creating an exceptionally durable, wear-resistant layer with uniform coverage, even on complex shapes. However, its main disadvantage stems from the very high temperatures required, which can make the final coated part more brittle and limits the types of materials it can be applied to.

The central trade-off of CVD is straightforward: it achieves superior coating adhesion and uniformity through a high-temperature chemical reaction, but this same heat restricts its use to substrates that can withstand it and can introduce stress that makes the coating brittle.

The Core Advantages of CVD Coating

The strengths of the CVD process are directly tied to its use of a chemical reaction to form the coating layer by layer.

Superior Adhesion and Wear Resistance

Because the CVD process forms the coating through a chemical reaction with the substrate, the bond is exceptionally strong. This results in superior adhesion compared to many other methods.

This strong bond contributes to a coating that is highly resistant to abrasion and wear, making it ideal for high-stress applications.

Uniform Coverage on Complex Shapes

CVD uses precursor gases that flow around the part inside a reaction chamber. This is not a "line-of-sight" process.

As a result, the coating can be deposited uniformly across all surfaces, including internal channels, complex curves, and irregularly shaped tools like drill bits.

Versatility in Deposited Materials

The CVD process is highly versatile and can be used to deposit a wide range of materials.

This includes dielectric films (like silicon dioxide), semiconductor materials, metals, and various compounds, making it valuable in both tooling and electronics manufacturing.

The Critical Disadvantages of CVD Coating

The primary limitations of CVD are a direct consequence of the intense heat required to initiate the chemical reaction.

High Processing Temperatures

CVD typically requires very high temperatures, often between 800°C and 1000°C.

This heat limits the process to substrate materials that have very high temperature resistance, such as cemented carbide. Many common steels and other alloys cannot be coated without being damaged or losing their temper.

Risk of Brittleness and Cracking

The CVD process deposits a relatively thick coating, often 10-20μm. As the part cools from the high processing temperature, this thick layer generates significant tensile stress.

This internal stress is like a tightly stretched skin, making the coating brittle. It can lead to the formation of fine cracks, which may spread and cause the coating to peel or flake off when subjected to external impact.

Unsuitability for Interrupted Cutting

The brittleness caused by tensile stress makes CVD-coated tools less suitable for applications with non-uniform forces, such as milling.

In an interrupted cut, the tool tip is repeatedly impacted, which can easily propagate the micro-cracks in a brittle CVD coating and lead to premature failure.

Understanding the Trade-offs: CVD vs. PVD

To fully grasp CVD's limitations, it's helpful to compare it to its main alternative, Physical Vapor Deposition (PVD).

Temperature and Material Choice

CVD's high temperature (800-1000°C) severely restricts the base materials you can use.

PVD operates at much lower temperatures (around 500°C), making it safe for a much wider range of materials, including heat-sensitive tool steels.

Coating Thickness and Stress

CVD creates a thicker coating (10-20μm) with inherent tensile stress (pulling apart), which increases brittleness.

PVD creates a much thinner coating (3-5μm) with favorable compressive stress (squeezing together). This compressive stress actually helps prevent cracks from forming and spreading, making PVD tools tougher and better for interrupted cuts.

Blade Sharpness and Cutting Force

The thicker coating of CVD can slightly round the sharp edge of a cutting tool.

PVD's thinner coating better preserves the original sharpness of the blade, which can reduce cutting forces and heat generation during operation.

Making the Right Choice for Your Application

Choosing between coating technologies requires a clear understanding of your material and the demands of the application.

- If your primary focus is maximum wear resistance on a heat-tolerant material: CVD is often the superior choice due to its thick, well-adhered coating, ideal for continuous cutting operations.

- If you are coating heat-sensitive materials or need toughness for interrupted cutting: PVD is the clear choice due to its lower processing temperature and favorable compressive stress.

- If you need to coat complex internal geometries uniformly: CVD's gas-based, non-line-of-sight process provides more comprehensive coverage than standard PVD.

Ultimately, understanding these fundamental trade-offs empowers you to select the coating technology that best aligns with your specific performance requirements.

Summary Table:

| Aspect | CVD Coating | PVD Coating |

|---|---|---|

| Process Temperature | 800°C - 1000°C | ~500°C |

| Coating Thickness | 10-20μm | 3-5μm |

| Internal Stress | Tensile (Brittle) | Compressive (Tough) |

| Best For | Continuous cutting, complex shapes | Interrupted cuts, heat-sensitive materials |

Need Expert Guidance on the Right Coating for Your Tools?

Choosing between CVD and PVD is critical for your tool's performance and longevity. The high-temperature CVD process delivers exceptional wear resistance and uniform coverage on complex geometries, but its inherent brittleness can be a drawback for interrupted cuts. For applications requiring toughness and compatibility with heat-sensitive materials, PVD's lower temperature and compressive stress are superior.

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and manufacturing facilities. Our experts can help you analyze your specific application—whether it's continuous machining, milling, or coating complex tooling—to recommend the optimal coating technology.

Let us help you enhance your tool life and machining efficiency. Contact our coating specialists today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition