In short, diamond identification is the gemological process of verifying that a stone is, in fact, a diamond and determining its origin—whether it is natural or lab-grown. It uses a series of tests, from simple handheld tools to sophisticated laboratory equipment, to distinguish genuine diamonds from simulants (look-alikes like cubic zirconia) and synthetic diamonds.

The core challenge of diamond identification has shifted. While basic tools can easily spot most "fakes," they are completely unable to distinguish a natural diamond from a lab-grown one. For this, definitive identification now depends entirely on advanced laboratory analysis.

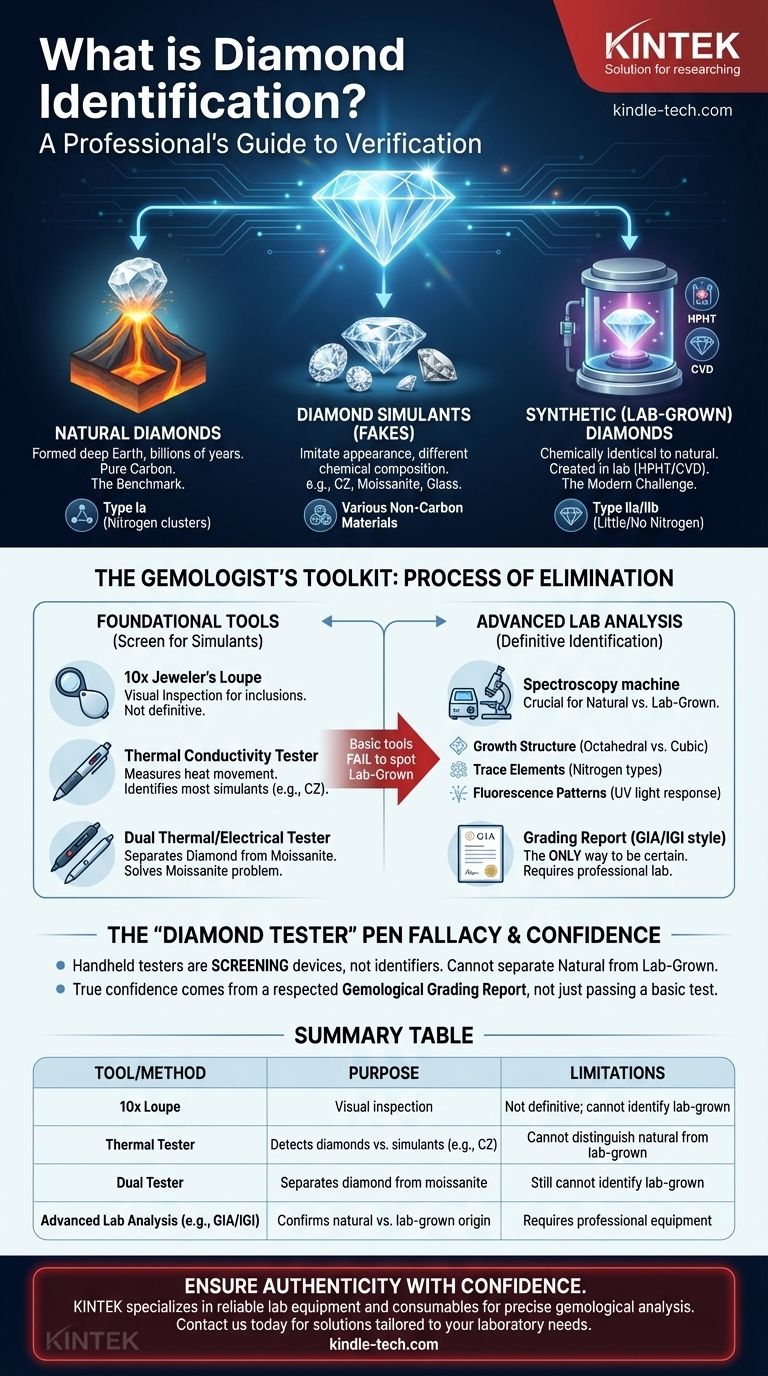

The Three Categories of "Diamond"

To understand identification, you must first understand what you are testing for. Any stone presented as a diamond falls into one of three distinct categories.

Natural Diamonds

These are crystals of pure carbon formed deep within the Earth's mantle over billions of years and brought to the surface by volcanic eruptions. They are the benchmark against which all others are measured.

Diamond Simulants

These are stones that imitate the appearance of a diamond but have entirely different chemical compositions and physical properties. Common examples include Cubic Zirconia (CZ), Moissanite, and glass. They are often called "fakes."

Synthetic (Lab-Grown) Diamonds

These are chemically, physically, and optically identical to natural diamonds. They are real diamonds, created in a laboratory using technologies like High Pressure/High Temperature (HPHT) or Chemical Vapor Deposition (CVD). Distinguishing them from natural diamonds is the primary challenge in modern gemology.

The Gemologist's Toolkit: From Basic to Advanced

Identification is a process of elimination, starting with simple tools and escalating to complex machinery as needed.

Foundational Tools: Screening for Simulants

The first step is to rule out common fakes. A professional often starts with two simple tools.

A 10x jeweler's loupe is used for magnification. A gemologist looks for inclusions—tiny internal characteristics—that are typical of natural diamonds. While helpful, this is not a definitive test.

A thermal conductivity tester, often called a "diamond pen," is the most common field tool. It measures how quickly heat moves through the stone. Diamonds are exceptional thermal conductors, so they will register a positive result while simulants like cubic zirconia and glass will not.

The Moissanite Problem

Moissanite, a popular and durable diamond simulant, has thermal conductivity very similar to a diamond. Because of this, it will often pass a basic thermal test, giving a false positive.

To solve this, gemologists use a tester that also measures electrical conductivity. Natural diamonds (with rare exceptions) do not conduct electricity, but moissanite does. A dual-tester that checks for both thermal and electrical properties can reliably separate diamond from moissanite.

The Modern Challenge: Identifying Lab-Grown Diamonds

Basic field tools fail here. Because lab-grown diamonds are chemically diamonds, they have the same thermal and electrical properties as natural ones. They will pass all tests designed to weed out simulants.

Distinguishing a natural diamond from a lab-grown one requires a gemological laboratory. Experts use advanced equipment to look for subtle differences in:

- Growth Structure: Natural diamonds grow in an octahedral (eight-sided) crystal shape, while lab diamonds grow in different patterns depending on the method (e.g., cubic for HPHT).

- Trace Elements: The presence and distribution of elements like nitrogen are different. Most natural diamonds are "Type Ia," containing nitrogen in clusters, while many lab diamonds are "Type IIa" or "IIb," with very little or no nitrogen.

- Fluorescence Patterns: Natural and lab-grown diamonds often fluoresce differently under shortwave ultraviolet (SWUV) light, revealing distinct growth sector patterns.

Understanding the Trade-offs: The Limits of Field Testing

Relying on simple tools without understanding their limitations can lead to costly mistakes.

The "Diamond Tester" Pen Fallacy

Handheld "diamond testers" are screening devices, not definitive identifiers. They are designed to separate diamonds from the most common, inexpensive simulants. They cannot, and are not intended to, separate a natural diamond from a lab-grown diamond.

Why "Passing" a Test Isn't Enough

A stone that "passes" a thermal test could be a diamond or it could be moissanite. A stone that passes both thermal and electrical tests could be a natural diamond or a lab-grown diamond. Each test only narrows the possibilities.

The Role of the Grading Report

The only way to be certain of a diamond's identity and origin is through a full grading report from a respected gemological laboratory like the GIA (Gemological Institute of America) or IGI (International Gemological Institute). This report is the final word, based on the advanced scientific analysis that is impossible to perform in a jewelry store.

Making an Informed Decision

Your approach to identification should align with your goal.

- If your primary focus is quick verification against obvious fakes: A quality dual thermal/electrical conductivity tester is an effective tool for screening out simulants like Cubic Zirconia and Moissanite.

- If your primary focus is confirming Natural vs. Lab-Grown origin: Rely exclusively on a grading report from a top-tier, independent gemological laboratory. Field tools are not sufficient for this task.

- If your primary focus is buying with confidence: Always insist on a recent, verifiable grading report from a reputable lab as a non-negotiable condition of purchase.

True confidence in a diamond's identity comes not from a single test, but from the certainty of professional verification documented in a trusted gemological report.

Summary Table:

| Tool/Method | Purpose | Limitations |

|---|---|---|

| 10x Loupe | Visual inspection for inclusions | Not definitive; cannot identify lab-grown diamonds |

| Thermal Conductivity Tester | Detects diamonds vs. simulants (e.g., CZ) | Cannot distinguish natural from lab-grown diamonds |

| Dual Thermal/Electrical Tester | Separates diamond from moissanite | Still cannot identify lab-grown diamonds |

| Advanced Lab Analysis (e.g., GIA/IGI) | Confirms natural vs. lab-grown origin | Requires professional laboratory equipment |

Ensure the authenticity of your diamonds with confidence. KINTEK specializes in providing reliable lab equipment and consumables for precise gemological analysis. Whether you're a jeweler, gemologist, or lab professional, our tools support accurate diamond identification and verification. Contact us today to explore our solutions tailored to your laboratory needs!

Visual Guide

Related Products

- High Energy Vibratory Ball Mill for Lab Use

- Double Plate Heating Press Mold for Lab

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Infrared High Resistance Single Crystal Silicon Lens

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What is the use of furnace in a laboratory? Essential Tool for Material Transformation

- What is the evaporation method in physical vapour deposition? A Guide to Thin Film Coating Techniques

- Is sintering eco-friendly? Weighing Material Efficiency Against Energy Use

- What is the difference between dry oven and incubator? Choosing the Right Equipment for Your Lab

- What are the safety procedures for a water bath? A Guide to Preventing Electrical, Thermal, and Contamination Risks

- What temperature is glass sintering? Master the Precise Thermal Window for Your Glass

- What are the key features of slow pyrolysis and fast pyrolysis? Choose the Right Process for Bio-Oil or Biochar

- What is the purpose of a constant temperature incubator shaker? Master Quercetin Adsorption on Nanocomposites