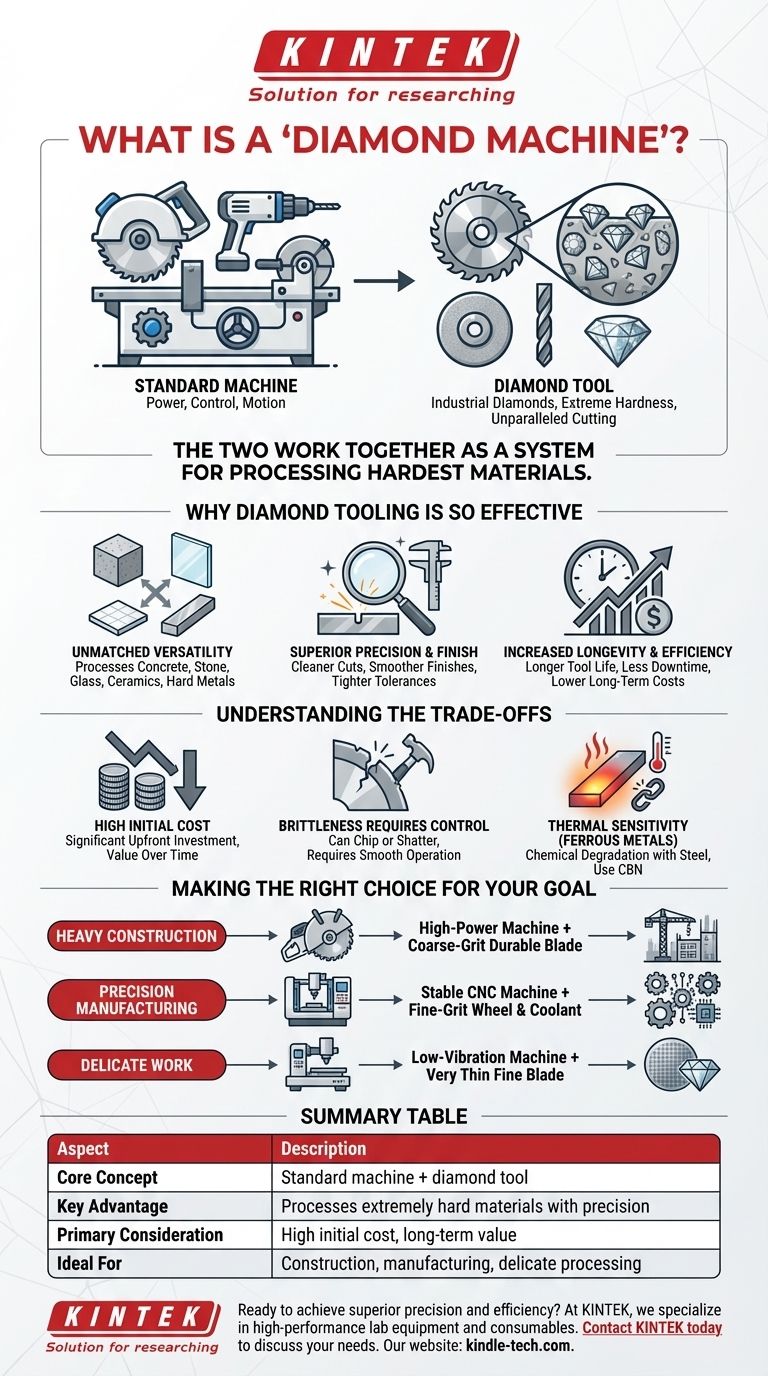

In practice, there is no single device called a "diamond machine." This term almost always refers to a standard machine—like a saw, grinder, or drill—that has been equipped with a specialized diamond tool. The performance comes not from the machine itself, but from the industrial diamond grains embedded in the tool it uses.

The key insight is that the "machine" provides the power and control, while the "diamond" provides the unparalleled cutting, grinding, or drilling capability. The two work together as a system to process the hardest materials with precision.

The Core Principle: Separating the Machine from the Tool

To understand how these systems work, it's essential to distinguish between the two main components: the machine that provides motion and the tool that does the actual work.

What is a Diamond Tool?

A diamond tool is not made of solid diamond. Instead, it consists of tiny industrial diamond grains fused to the functional part of the tool (like the edge of a blade or the tip of a drill bit) using a strong bonding material.

This design leverages the single most important property of diamond: its extreme hardness. As the hardest known natural material, it can cut, abrade, or drill virtually any other substance.

The Role of the Machine

The machine is the delivery system for the diamond tool's power. Its job is to provide the necessary speed, torque, and pressure to apply the tool to the workpiece effectively.

Common machines that use diamond tooling include concrete saws, core drills, CNC grinding machines, and precision lathes. The machine ensures the tool is applied with stability and control.

Why Diamond Tooling is So Effective

The use of diamond tooling is standard practice in demanding industries for a few critical reasons that go beyond simple hardness.

Unmatched Material Versatility

Because diamond is harder than almost anything else, diamond tooling can effectively process a vast range of tough materials, including concrete, stone, glass, ceramics, and hard metals.

Superior Precision and Finish

Diamond tools cut cleanly with less force than traditional abrasives. This results in cleaner cuts, smoother finishes, and tighter tolerances, which is critical in manufacturing and optics.

Increased Longevity and Efficiency

While more expensive initially, diamond tools wear down much more slowly than conventional abrasive tools. This leads to a longer tool life, less downtime for tool changes, and ultimately, lower long-term operating costs.

Understanding the Trade-offs

Diamond tooling is a powerful solution, but it is not without its specific limitations and considerations. Understanding these is key to using it correctly.

The High Initial Cost

The primary drawback is the upfront investment. Diamond tools are significantly more expensive than their carbide or standard abrasive counterparts. Their value is realized through their long-term durability and performance.

Brittleness Requires Control

Diamond is incredibly hard, but it is also brittle. This means it can chip or shatter under shock or improper load. The machine must be operated smoothly, with correct speeds and feeds, to protect the tool.

Thermal Sensitivity with Certain Metals

At the high temperatures generated when cutting ferrous metals like steel, diamond can undergo a chemical reaction that causes it to degrade. For these specific applications, other super-hard materials like Cubic Boron Nitride (CBN) are often a better choice.

Making the Right Choice for Your Goal

The ideal "diamond machine" is a system where the machine's capabilities are perfectly matched to the diamond tool and the material being worked.

- If your primary focus is heavy construction (cutting concrete or asphalt): You need a high-power, robust machine paired with a durable, coarse-grit diamond blade designed for aggressive material removal.

- If your primary focus is precision manufacturing (grinding hardened steel or ceramics): You require a highly stable CNC machine capable of precise control, using a fine-grit diamond wheel and a coolant system to manage heat.

- If your primary focus is delicate work (slicing silicon wafers or gemstones): The emphasis is on a low-vibration machine with variable speed, using a very thin and fine diamond blade to minimize material loss and prevent cracking.

Ultimately, harnessing the power of diamond is about choosing the right tool and pairing it with the right machine to achieve your specific goal.

Summary Table:

| Aspect | Description |

|---|---|

| Core Concept | A standard machine (saw, grinder, drill) equipped with a diamond-embedded tool. |

| Key Advantage | Processes extremely hard materials (concrete, ceramics, glass) with superior precision and finish. |

| Primary Consideration | High initial tool cost, but offers long-term value through exceptional durability and reduced downtime. |

| Ideal For | Construction, precision manufacturing, and delicate material processing where accuracy and efficiency are critical. |

Ready to achieve superior precision and efficiency in your material processing?

At KINTEK, we specialize in providing the high-performance lab equipment and consumables that power industries reliant on precision cutting, grinding, and drilling. Whether you're in construction, manufacturing, or research, pairing the right machine with the right diamond tool is crucial for your success.

Our experts can help you select the ideal equipment to maximize the benefits of diamond tooling for your specific applications, ensuring cleaner cuts, smoother finishes, and lower long-term costs.

Contact KINTEK today to discuss your needs and discover how our solutions can enhance your operational capabilities.

Visual Guide

Related Products

- 12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Single Horizontal Jar Mill

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- Can a diamond be created in a laboratory? The Science Behind Genuine Lab-Grown Diamonds

- What is the difference between CVD diamond and natural diamond? A Guide to Making an Informed Choice

- What are the ethical benefits of lab-grown diamonds? A Conflict-Free, Sustainable Choice

- What is the process of MPCVD? Grow High-Purity Diamond & Advanced Films

- What is the growth rate of CVD diamond? Discover the Secret to High-Purity Lab-Grown Gems

- What is a microwave plasma reactor? Unlock Precision Synthesis of High-Performance Materials

- Do natural diamonds last longer? The Truth About Diamond Durability and Value

- What's the difference between CVD and HPHT? Choosing the Right Lab-Grown Diamond Method