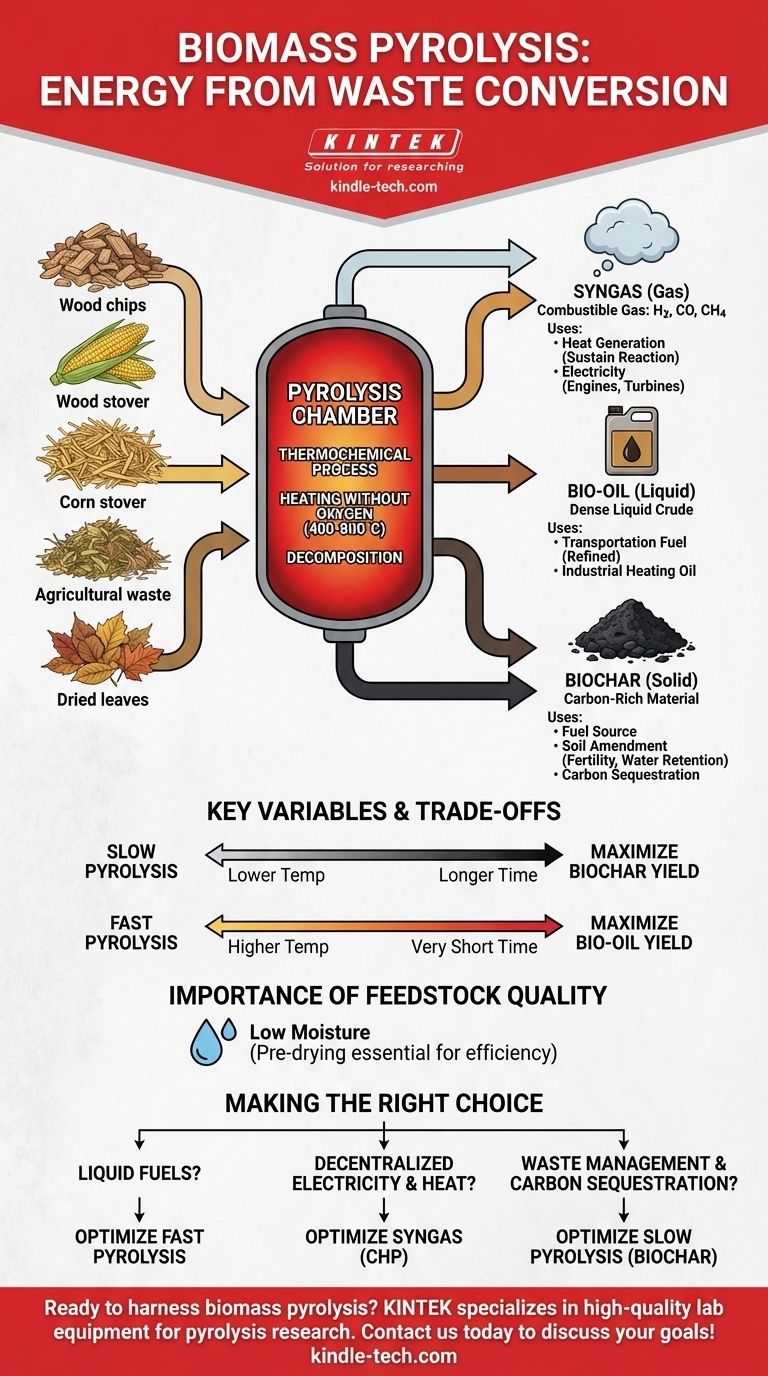

In essence, biomass pyrolysis is a thermochemical process that converts organic materials, such as agricultural waste or purpose-grown crops, into energy and valuable byproducts. It achieves this by heating the biomass to high temperatures in an environment with little to no oxygen. This prevents combustion and instead causes the material to decompose into a combustible gas, a liquid oil, and a solid, carbon-rich char.

Biomass pyrolysis is best understood not as a single energy source, but as a flexible conversion technology. It transforms organic waste into a portfolio of solid, liquid, and gaseous energy products, allowing operators to tailor the output based on specific process conditions and goals.

The Core Pyrolysis Process

The Principle: Heating Without Oxygen

Pyrolysis is the process of thermal decomposition. By heating organic matter in an oxygen-starved chamber, we prevent it from simply burning.

Instead of combusting and releasing its energy as uncontrolled heat, the biomass breaks down chemically. Its complex organic polymers decompose into smaller, more volatile molecules that can be captured as distinct products.

The Inputs: A Wide Range of Biomass

The "biomass" feedstock can be sourced from a wide variety of organic materials. This flexibility is a key advantage of the technology.

Common inputs include agricultural residues (straw, husks), wood chips and sawdust, dedicated energy crops, and even organic waste streams from industrial processes.

The Outputs: A Portfolio of Energy Products

The true value of pyrolysis is in the separation of the biomass into three distinct and usable forms of energy and material.

The Gas: Syngas

The non-condensable gases produced are collectively known as syngas (synthesis gas). This is a fuel gas rich in hydrogen (H2), carbon monoxide (CO), and methane (CH4).

This syngas can be combusted to generate heat, often used to sustain the pyrolysis reaction itself, making the process more energy-efficient. It can also be used to power engines or turbines to generate electricity.

The Liquid: Bio-oil

As the hot gas from the pyrolyzer cools, a dense liquid known as bio-oil or pyrolysis oil condenses out. This is a form of crude oil derived from biomass.

Bio-oil holds potential as a transportation fuel or a heating oil for industrial boilers, though it often requires upgrading and refining to meet the quality standards of conventional fossil fuels.

The Solid: Biochar

The remaining solid material is a stable, carbon-rich substance called biochar or biomass charcoal. This product is similar to traditional charcoal.

Biochar is an excellent fuel source in its own right. It can also be used as a powerful soil amendment, improving water retention and soil fertility while sequestering carbon in the ground for long periods.

Understanding the Key Variables and Trade-offs

The efficiency of a biomass pyrolysis plant and the ratio of its final products are not fixed. They are highly dependent on several controllable factors, which present critical operational trade-offs.

The Impact of Temperature and Time

The temperature and the residence time (how long the biomass stays in the reactor) are the most critical variables for determining the product yield.

- Slow Pyrolysis: Lower temperatures and longer residence times favor the production of solid biochar.

- Fast Pyrolysis: Higher temperatures and very short residence times maximize the yield of liquid bio-oil.

This trade-off allows operators to decide whether they want to prioritize a solid fuel and carbon sequestration product (biochar) or a liquid energy carrier (bio-oil).

The Importance of Feedstock Quality

The type and condition of the biomass feedstock significantly impact the process. The moisture content is particularly crucial.

Wet biomass requires a large amount of energy just to boil off the water before pyrolysis can begin, which severely reduces the net energy output of the system. Pre-drying the feedstock is almost always necessary for an efficient operation.

The Challenge of Product Refinement

The products of pyrolysis are not always "drop-in" replacements for their fossil fuel counterparts. Bio-oil, for instance, is often acidic and less stable than petroleum crude, requiring further processing before it can be used in standard engines.

Likewise, syngas may contain tars and impurities that need to be cleaned or "scrubbed" before it can be used in sensitive equipment like gas engines. This adds complexity and cost to the overall system.

Making the Right Choice for Your Goal

The optimal approach to biomass pyrolysis depends entirely on your primary objective. By controlling the process variables, you can steer production toward the most valuable output for your needs.

- If your primary focus is liquid fuels for transport or industry: You will need to optimize for fast pyrolysis to maximize bio-oil yield and plan for downstream refining capabilities.

- If your primary focus is decentralized electricity and heat: Syngas is your key product, enabling a combined heat and power (CHP) system that can make the entire operation self-sufficient.

- If your primary focus is waste management and carbon sequestration: Slow pyrolysis is the ideal path, as it maximizes the yield of biochar, a stable solid that improves soil and locks away carbon.

Ultimately, biomass pyrolysis offers a flexible technological pathway to convert organic materials into valuable energy, with the final output tailored by precise process control.

Summary Table:

| Product | Description | Primary Use |

|---|---|---|

| Syngas | Combustible gas (H2, CO, CH4) | Heat, electricity generation |

| Bio-oil | Liquid fuel from condensed vapors | Transportation, industrial heating |

| Biochar | Solid carbon-rich material | Fuel, soil amendment, carbon sequestration |

Ready to harness the power of biomass pyrolysis for your lab or pilot project? KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-oil yield, analyzing syngas composition, or testing biochar properties, our reliable solutions help you achieve precise process control and accurate results. Contact us today to discuss how we can support your biomass conversion goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success