In essence, fast pyrolysis is a chemical recycling process that uses extremely rapid heating in an oxygen-free environment to break down plastic waste. Unlike slower methods, the primary goal of fast pyrolysis is to quickly convert the solid plastic into a liquid, known as pyrolysis oil, which can then be refined into fuel or used as a feedstock for new chemicals and plastics.

Fast pyrolysis is not just about heating plastic; it's about controlling the speed and temperature to maximize the creation of valuable liquid oil from low-value, mixed plastic waste that is often considered non-recyclable.

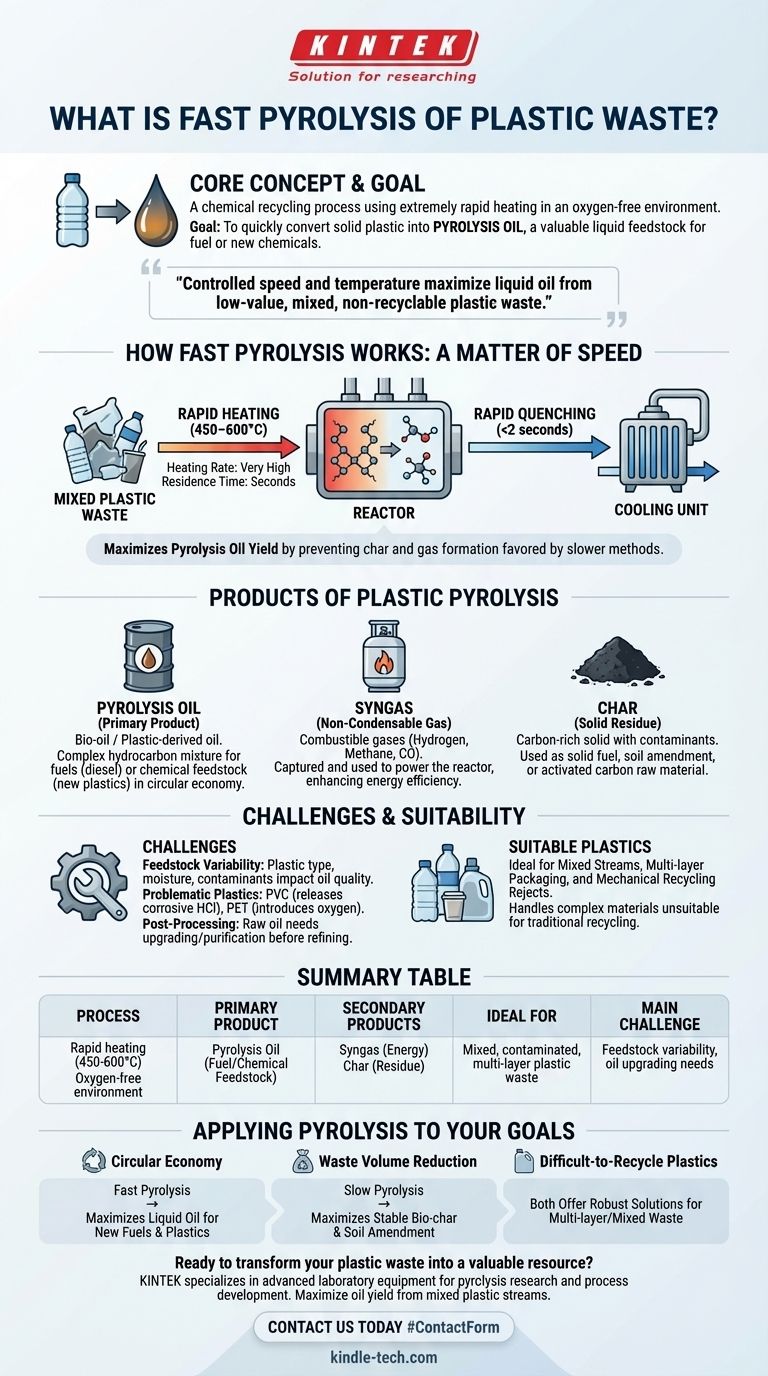

How Fast Pyrolysis Works: A Matter of Speed

The term "pyrolysis" describes thermal decomposition in the absence of oxygen. The "fast" qualifier is what defines the specific goals and outcomes of the process when applied to plastics.

The Core Principle: Thermal Decomposition

All pyrolysis works by heating material to high temperatures without oxygen. This prevents combustion (burning) and instead causes the long polymer chains that make up plastic to break apart into smaller, more valuable molecules.

The "Fast" in Fast Pyrolysis

The key variables are heating rate and residence time. Fast pyrolysis uses very high heating rates to bring the plastic to a target temperature (typically 450–600°C) in seconds. The resulting vapors are also removed and cooled (quenched) very quickly, usually in less than two seconds.

The Goal: Maximizing Liquid Oil Yield

This rapid heating and cooling process is specifically designed to maximize the production of pyrolysis oil. Slower pyrolysis methods, by contrast, use lower heating rates and longer processing times, which favors the production of solid char and gas.

The Products of Plastic Pyrolysis

Fast pyrolysis breaks plastic down into three primary outputs, with the oil being the most desired product.

Pyrolysis Oil

This is the main liquid product, often referred to as bio-oil or plastic-derived oil. It's a complex mixture of hydrocarbons that can be upgraded and refined into fuels like diesel or used as a chemical feedstock to create new plastics, achieving a circular economy.

Syngas (Non-Condensable Gas)

This is a mixture of combustible gases (like hydrogen, methane, and carbon monoxide) that do not condense into a liquid upon cooling. This gas is almost always captured and used to provide the energy needed to power the pyrolysis reactor itself, making the process more energy-efficient.

Char (Solid Residue)

A small amount of solid, carbon-rich material called char is also produced. This residue contains contaminants and fillers from the original plastic waste. It can be used as a solid fuel, a soil amendment, or as a raw material for producing activated carbon.

Understanding the Trade-offs and Challenges

While promising, fast pyrolysis is not a silver bullet. Understanding its technical challenges is critical for a realistic assessment.

The Problem of Feedstock Variability

The type and quality of plastic waste going into the reactor are highly variable. Differences in plastic composition, moisture levels, and non-plastic contaminants directly impact the quality and yield of the final pyrolysis oil.

The Issue with Certain Plastics

Some plastics create significant problems. PVC (Polyvinyl chloride), for example, releases corrosive hydrochloric acid when heated, which can damage equipment. PET (Polyethylene terephthalate) can also introduce oxygen into the oil, reducing its quality.

The Need for Post-Processing

The raw pyrolysis oil produced is not a "drop-in" fuel. It is often acidic, unstable, and contains contaminants that must be removed through a secondary upgrading or purification process before it can be used in conventional refineries or chemical plants.

Which Plastics Are Suitable?

One of the great strengths of pyrolysis is its ability to handle waste streams that are unsuitable for traditional mechanical recycling.

Ideal Candidates

Pyrolysis is particularly effective for processing mixed plastics. This includes post-consumer packaging, plastics segregated from municipal solid waste, and rejects from mechanical recycling facilities that are too contaminated to process further.

Why It Handles Mixed and Multi-Layer Waste

Because the process breaks down the plastics at a molecular level, it is more tolerant of mixed streams and complex materials like multi-layer food packaging. These materials are nearly impossible to separate and recycle mechanically, making pyrolysis a key recovery pathway.

Applying Pyrolysis to Your Waste Management Goals

The decision to use fast pyrolysis depends entirely on your specific objective for the plastic waste stream.

- If your primary focus is a circular economy and new chemical production: Fast pyrolysis is the superior method because it maximizes the yield of liquid oil, a versatile feedstock for creating new fuels and plastics.

- If your primary focus is waste volume reduction and creating a soil amendment: A slow pyrolysis process may be more suitable, as it is optimized to produce a higher yield of stable bio-char.

- If your primary focus is managing difficult-to-recycle plastics: Both fast and slow pyrolysis offer a robust solution for multi-layer, mixed, or contaminated plastics that have no other viable recycling pathway.

Ultimately, fast pyrolysis is a powerful chemical recycling technology that transforms low-value plastic waste into a valuable resource.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process | Rapid heating (450-600°C) in an oxygen-free environment |

| Primary Product | Pyrolysis Oil (for fuel/chemical feedstock) |

| Secondary Products | Syngas (for process energy) & Char (solid residue) |

| Ideal For | Mixed, contaminated, and multi-layer plastic waste |

| Main Challenge | Feedstock variability and need for oil upgrading |

Ready to transform your plastic waste into a valuable resource?

KINTEK specializes in advanced laboratory equipment for pyrolysis research and process development. Our reactors and analytical tools help you optimize conditions to maximize oil yield from mixed plastic streams.

Contact us today using the form below to discuss how our solutions can support your chemical recycling and circular economy goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control