At its core, Chemical Vapor Deposition (CVD) is a material processing technique used to apply high-performance, solid coatings onto a surface, known as a substrate. It achieves this not by painting or spraying, but by introducing reactive gases into a chamber where they decompose and form a thin, solid film on the heated substrate. The result is a coating that is grown atom-by-atom, leading to exceptional purity and structural quality.

Chemical Vapor Deposition is the definitive method for creating exceptionally pure, dense, and durable material layers. Its key advantage is the ability to conformally coat complex shapes, but this precision comes with a significant trade-off: a high processing temperature that limits the types of materials it can be used on.

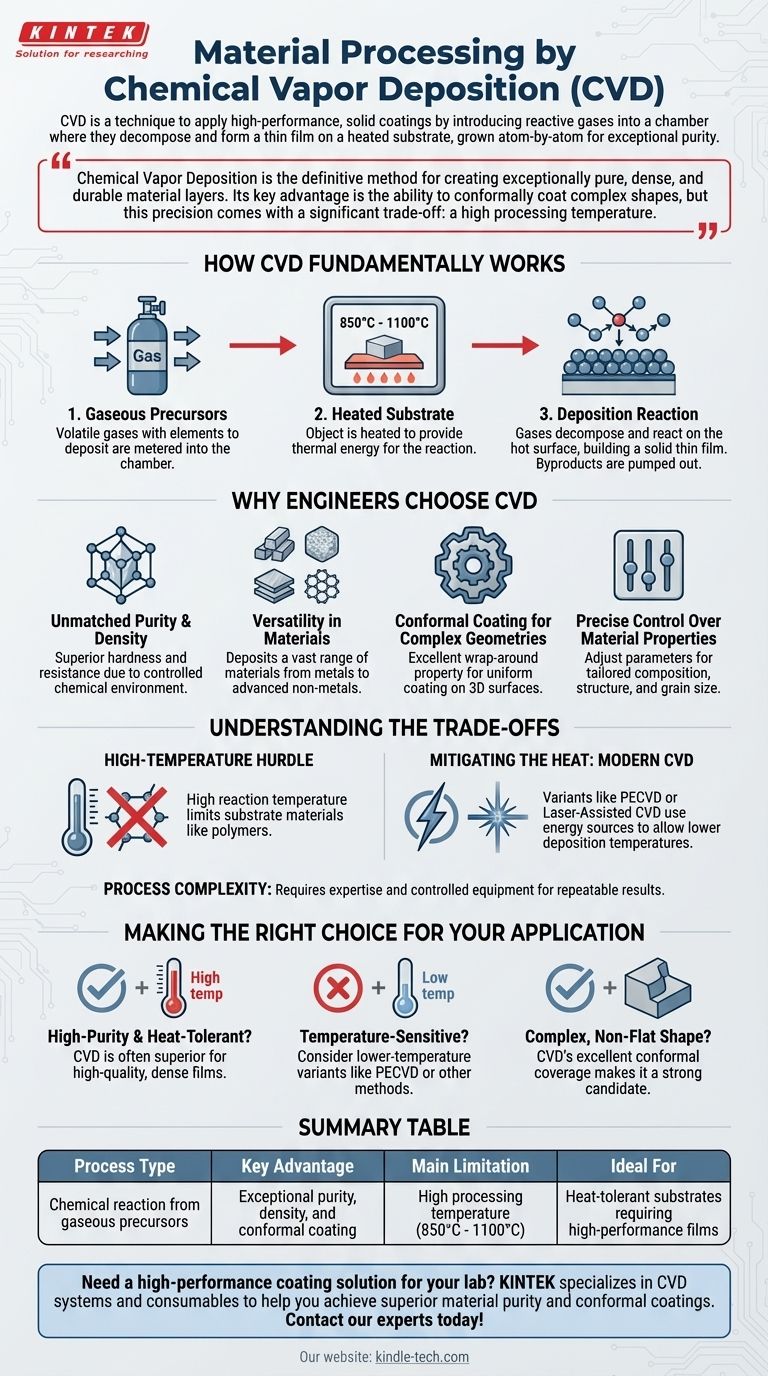

How CVD Fundamentally Works

Understanding the CVD process is key to appreciating its unique capabilities. The entire process takes place within a controlled vacuum chamber and can be broken down into a few fundamental steps.

The Gaseous Precursors

The process begins with one or more volatile gases, called precursors, which contain the elements you want to deposit. These gases are precisely metered and fed into the reaction chamber.

The Heated Substrate

Inside the chamber, the object to be coated—the substrate—is heated to a very high temperature, often between 850°C and 1100°C. This heat is not just for warming; it provides the critical thermal energy needed to trigger a chemical reaction.

The Deposition Reaction

When the precursor gases come into contact with the hot substrate, they decompose and react. This chemical reaction results in the formation of a solid material that "deposits" onto the substrate surface, building up a thin film. Other gaseous byproducts from the reaction are simply pumped out of the chamber.

Why Engineers Choose CVD

CVD is not chosen for its simplicity, but for its superior results. Engineers in fields like semiconductor manufacturing and advanced materials rely on it when performance is non-negotiable.

Unmatched Purity and Density

Because the film is built from a chemical reaction in a controlled environment, the resulting layers are extremely pure and dense. This leads to materials with superior hardness and resistance to damage compared to those made with other coating methods.

Versatility in Materials

CVD is remarkably flexible. It can be used to deposit a vast range of materials, including metal films, non-metal films like silicon nitride, multi-component alloys, complex ceramics, and even advanced materials like graphene.

Conformal Coating for Complex Geometries

One of CVD's most significant advantages is its excellent wrap-around property. The gas precursors can reach every part of a complex, three-dimensional surface, resulting in a uniform, conformal coating that is impossible to achieve with line-of-sight methods like spraying.

Precise Control Over Material Properties

By carefully adjusting process parameters like temperature, pressure, and gas flow rates, engineers can precisely control the final properties of the coating. This includes its chemical composition, crystal structure, and grain size, allowing for highly tailored material performance.

Understanding the Trade-offs

No process is perfect. The power of CVD comes with significant constraints that must be managed.

The High-Temperature Hurdle

The most significant limitation of traditional CVD is its high reaction temperature. Many potential substrate materials, such as polymers or certain metal alloys, cannot withstand the heat and would be damaged or destroyed during the process.

Mitigating the Heat: Modern CVD Variants

To overcome the temperature limitation, specialized versions of CVD have been developed. Techniques like Plasma-Enhanced CVD (PECVD) or Laser-Assisted CVD use plasma or lasers to provide the necessary reaction energy, allowing deposition to occur at much lower temperatures.

Process Complexity

While the ability to control deposition parameters is an advantage, it also introduces complexity. Achieving a specific, repeatable outcome requires significant expertise and tightly controlled equipment to manage the delicate balance of variables.

Making the Right Choice for Your Application

Selecting the right deposition method requires balancing your performance needs against material and process constraints.

- If your primary focus is ultimate material purity and performance on a heat-tolerant substrate: CVD is often the superior choice for its ability to produce high-quality, dense films.

- If your primary focus is coating a temperature-sensitive material like a polymer: Traditional CVD is unsuitable; you must investigate lower-temperature variants like PECVD or entirely different methods.

- If your primary focus is achieving a uniform coating on a complex, non-flat shape: CVD's excellent conformal coverage makes it a very strong candidate.

Understanding these core principles allows you to select and specify the right deposition technology for your precise engineering goal.

Summary Table:

| Key Aspect | CVD Characteristic |

|---|---|

| Process Type | Chemical reaction from gaseous precursors |

| Key Advantage | Exceptional purity, density, and conformal coating |

| Main Limitation | High processing temperature (850°C - 1100°C) |

| Ideal For | Heat-tolerant substrates requiring high-performance films |

Need a high-performance coating solution for your lab?

KINTEK specializes in providing advanced lab equipment, including CVD systems and consumables, to help you achieve superior material purity and conformal coatings on complex geometries. Our expertise ensures you get the right technology for your specific substrate and performance requirements.

Contact our experts today to discuss how CVD can enhance your research and development!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth