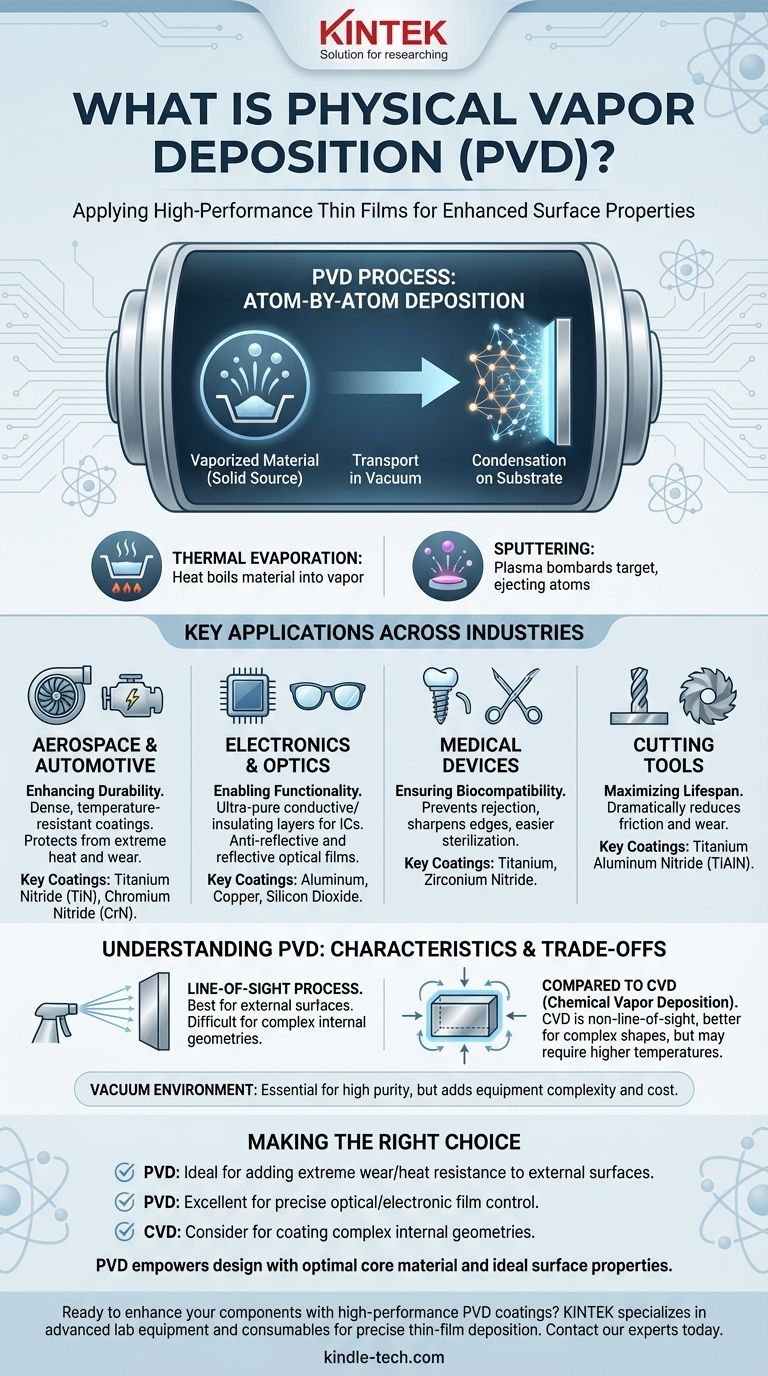

At its core, Physical Vapor Deposition (PVD) is used to apply high-performance thin films onto a wide variety of surfaces. This process is critical in industries ranging from aerospace and electronics to medical devices and cutting tools. By depositing a vaporized material onto a substrate in a vacuum, PVD enhances a component's durability, function, or appearance in ways the base material cannot achieve on its own.

PVD is not about making an object, but about fundamentally improving its surface. It allows engineers to add specific properties—like extreme hardness, heat resistance, or precise optical characteristics—by depositing an ultra-thin layer of a different material atom by atom.

The Core Function: Modifying Surfaces with Thin Films

Physical Vapor Deposition is a family of processes that all share one goal: to create a very thin, functional coating on a part, often called a substrate.

What is a "Thin Film"?

A thin film is a layer of material ranging from a few nanometers to several micrometers in thickness. This layer is engineered to have specific properties that the underlying object, or substrate, lacks.

These films are not like a coat of paint; they are atomically bonded to the surface, creating a new, integrated surface with superior characteristics.

How PVD Works: The Basic Principle

All PVD processes take place inside a vacuum chamber to ensure the purity of the film. The basic steps involve vaporizing a solid source material, transporting that vapor across the chamber, and having it condense onto the substrate.

The two most common methods are thermal evaporation, which uses heat to boil the material into a vapor, and sputtering, which uses a plasma to bombard a target and eject atoms that then land on the substrate.

Key Applications Across Industries

The unique capabilities of PVD make it essential for creating high-value products where surface performance is critical.

For Aerospace and Automotive: Enhancing Durability

PVD is used to apply dense, temperature-resistant coatings to components like jet engine turbine blades. These films protect the parts from the extreme heat and stress of operation, significantly extending their lifespan.

In automotive applications, it provides hard, wear-resistant coatings for engine parts and decorative finishes that are far more durable than traditional chrome plating.

For Electronics and Optics: Enabling Functionality

The semiconductor industry relies heavily on PVD to deposit the precise, ultra-pure layers of conductive and insulating materials that form integrated circuits.

PVD is also used to apply optical films. This includes anti-reflective coatings on eyeglass lenses and solar panels, as well as the reflective layers in holographic displays and mirrors.

For Medical Devices: Ensuring Biocompatibility

Medical implants and surgical tools are frequently coated using PVD. These coatings can make an implant more biocompatible, preventing rejection by the body, and can give surgical tools an extremely hard, sharp, and easy-to-sterilize edge.

For Cutting Tools: Maximizing Lifespan

Drill bits, milling cutters, and other industrial tools are often coated with materials like titanium nitride using PVD. This hard, corrosion-resistant film dramatically reduces friction and wear, allowing tools to last longer and perform better.

Understanding the Trade-offs

While powerful, PVD is not a universal solution. Understanding its characteristics is key to using it effectively.

PVD is a "Line-of-Sight" Process

Because the vaporized material travels in a straight line from the source to the substrate, PVD works best on external surfaces. It is very difficult to coat complex internal geometries or the backsides of objects without complex rotating fixtures.

The Role of the Vacuum

Operating in a vacuum is essential for creating high-purity films free from contamination. However, this requirement means PVD equipment is complex and represents a significant capital investment.

A Note on Chemical Vapor Deposition (CVD)

PVD is often compared to Chemical Vapor Deposition (CVD), which uses chemical reactions to grow a film on a surface. Unlike PVD, CVD is a non-line-of-sight process, making it better for coating complex shapes. While sometimes more affordable, CVD processes often require higher temperatures and can be less pure than PVD.

Making the Right Choice for Your Goal

Deciding whether PVD is appropriate depends entirely on the desired outcome for your component.

- If your primary focus is adding wear or heat resistance to an external surface: PVD is an industry-standard choice for creating extremely hard, dense, and pure coatings.

- If your primary focus is depositing a precise optical or electronic film: PVD offers excellent control over film thickness and composition, making it ideal for semiconductors and solar cells.

- If your primary focus is coating a complex internal geometry: You should investigate alternative methods like Chemical Vapor Deposition (CVD), which is not limited by line-of-sight.

Ultimately, PVD empowers you to design with the best material for the core structure, while applying the ideal material for the surface interaction.

Summary Table:

| Application | Key Benefit | Common PVD Coatings |

|---|---|---|

| Aerospace & Automotive | Extreme heat & wear resistance | Titanium Nitride (TiN), Chromium Nitride (CrN) |

| Electronics & Optics | Precise conductive/insulating layers | Aluminum, Copper, Silicon Dioxide |

| Medical Devices | Biocompatibility & sterilization | Titanium, Zirconium Nitride |

| Cutting Tools | Extended lifespan & reduced friction | Titanium Aluminum Nitride (TiAlN) |

Ready to enhance your components with high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for precise thin-film deposition. Whether you're in aerospace, medical, or electronics, our solutions help you achieve superior surface properties. Contact our experts today to discuss your project needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells