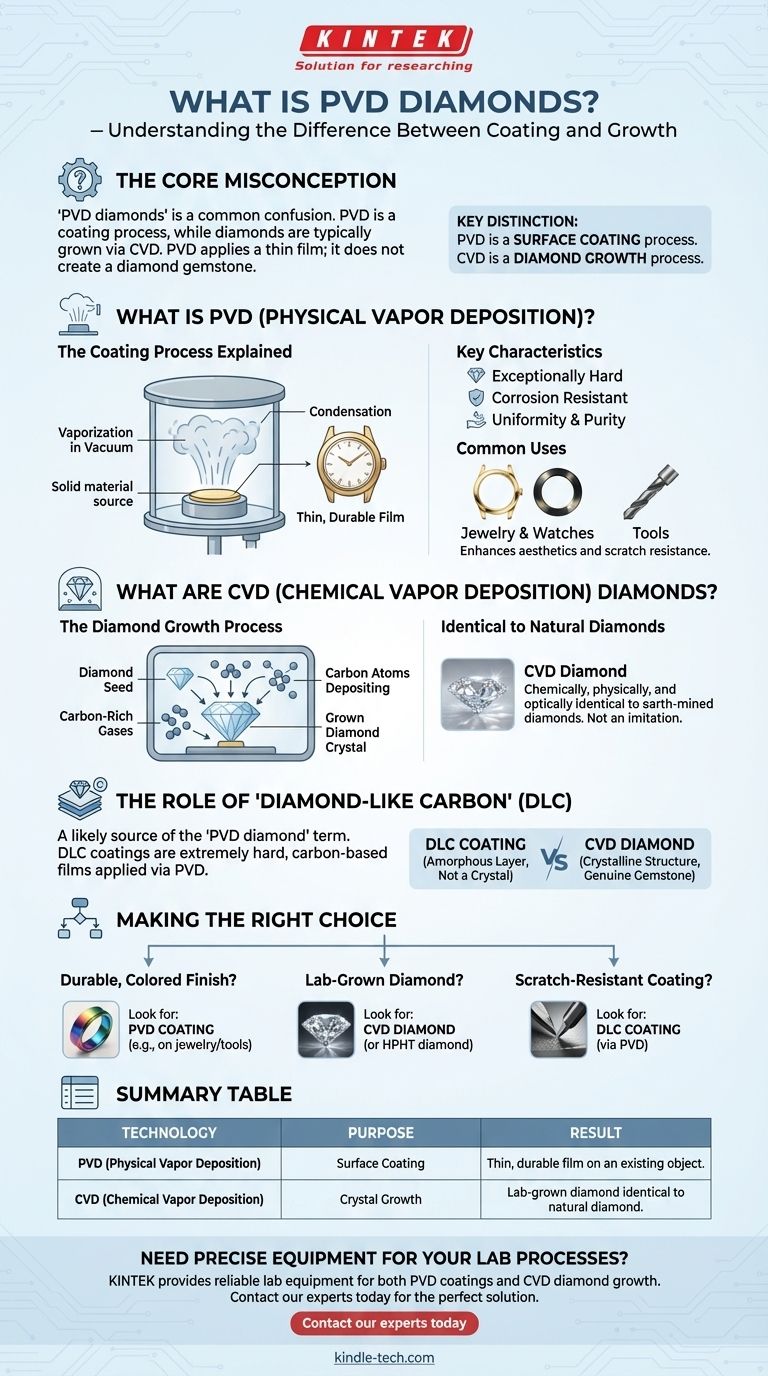

"PVD diamonds" is a common point of confusion, but the term itself is not technically accurate for a type of gemstone. The mix-up arises because two different technologies are being combined: PVD is a coating process, while diamonds are typically grown in a lab using a process called CVD. PVD (Physical Vapor Deposition) is a technique used to apply a thin, durable film onto a surface, not to create a diamond.

The key distinction to remember is that PVD is a surface coating process, while CVD is a diamond growth process. People often encounter "PVD" in the context of durable, colored finishes on jewelry or watches, not in the creation of the gemstone itself.

What is PVD (Physical Vapor Deposition)?

PVD is a highly regarded industrial process used to create a thin, protective, or decorative film on top of another material, known as a substrate.

The Coating Process Explained

In a PVD process, a solid coating material is vaporized in a vacuum chamber. This vapor then travels and condenses onto the object being coated, forming a very thin but extremely durable and well-adhered layer.

Key Characteristics of PVD Coatings

Based on material science, PVD coatings are known for being exceptionally hard and highly resistant to corrosion and tarnishing. They are prized for their uniformity and purity, offering superior performance compared to traditional electroplating.

Common Uses in Jewelry and Tools

This process is frequently used to apply gold-toned, black, or other colored finishes to stainless steel watches, jewelry, and tools. It enhances both the aesthetic appeal and the scratch resistance of the underlying metal.

What are CVD (Chemical Vapor Deposition) Diamonds?

CVD diamonds are not a coating; they are genuine diamonds grown in a controlled laboratory environment.

The Diamond Growth Process

The CVD process starts with a tiny diamond "seed." This seed is placed in a sealed chamber filled with carbon-rich gases. Under specific conditions, these gases break down, and carbon atoms deposit onto the seed, growing a real diamond, layer by layer.

Identical to Natural Diamonds

The result of the CVD process is a stone that is chemically, physically, and optically identical to a diamond mined from the earth. They are not imitations; they are simply created via a different origin.

Understanding the Core Misconception

The confusion between PVD and CVD stems from the fact that both are advanced vacuum-deposition technologies used in high-value products, but their purpose and output are fundamentally different.

Process vs. Product

PVD is a process applied to a product. It adds a functional or decorative layer on top of an existing object, like a watch case.

CVD is a process that creates the product itself. The diamond is the end result of the entire procedure.

The Role of "Diamond-Like Carbon" (DLC)

A likely source of the term "PVD diamond" is the existence of Diamond-Like Carbon (DLC) coatings. These are extremely hard, carbon-based films that can be applied using a PVD process.

While a DLC coating has some properties similar to diamond (like hardness and low friction), it is not a crystalline diamond. It is an amorphous layer, not a gemstone.

Making the Right Choice for Your Goal

To ensure you get what you are looking for, focus on the function you need.

- If your primary focus is a durable, colored finish on metal: You are looking for a product with a PVD coating.

- If your primary focus is a lab-grown diamond identical to a natural one: You should be searching for a CVD diamond (or its alternative, an HPHT diamond).

- If your primary focus is an extremely scratch-resistant coating on a tool or watch: You are likely looking for a DLC coating, which is often applied using PVD.

Understanding the difference between a surface coating and a grown crystal empowers you to make a more informed and confident decision.

Summary Table:

| Technology | Purpose | Result |

|---|---|---|

| PVD (Physical Vapor Deposition) | Surface Coating | Thin, durable film on an existing object |

| CVD (Chemical Vapor Deposition) | Crystal Growth | Lab-grown diamond identical to natural diamond |

Need precise equipment for your lab processes? Whether you're working with advanced PVD coatings or growing CVD diamonds, KINTEK provides the reliable lab equipment and consumables you need for consistent, high-quality results. Contact our experts today to find the perfect solution for your laboratory's specific requirements.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition