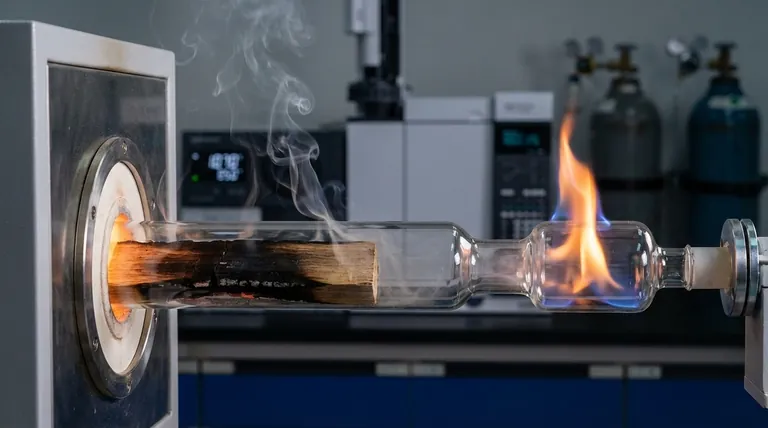

At its core, pyrolysis is the crucial first step that allows solid and liquid fuels to combust. It is the process of chemical decomposition caused by heating a material in an environment with little to no oxygen. This breaks the fuel down into flammable gases, and it is these gases—not the original solid or liquid—that actually mix with oxygen to create the flame we associate with fire.

Solid and liquid fuels do not burn directly. Instead, heat from a fire triggers pyrolysis, which releases flammable gases. It is these gases that mix with oxygen and ignite to produce the visible flame, making pyrolysis an essential precursor to most forms of combustion.

How Combustion Actually Works: A Two-Stage Process

To truly understand fire, you must see it not as a single event, but as a sequence. Pyrolysis is the hidden first stage that makes the second, more visible stage possible.

Stage 1: Pyrolysis (The Gas Factory)

When a solid fuel like wood is heated, the area directly at its surface becomes starved of oxygen because the initial combustion consumes it. This combination of high heat and low oxygen creates the perfect conditions for pyrolysis.

The intense heat breaks down the complex molecules of the wood, causing it to "off-gas" a mixture of flammable vapors and particulates. This is happening constantly at the surface of the fuel, creating a localized zone that is actively manufacturing fuel for the flame.

Stage 2: Gaseous Combustion (The Visible Flame)

These hot, flammable gases released during pyrolysis rise and mix with the surrounding air, which is rich in oxygen.

Once this gas-oxygen mixture reaches the right concentration and temperature, it ignites. This rapid oxidation reaction is what we perceive as a flame. The flame itself is a zone of burning gases, physically separate from the solid fuel below it.

The Three Products of Pyrolysis

Pyrolysis doesn't just create one thing; it deconstructs a fuel source into three distinct categories of substances, each playing a different role in the combustion process.

Flammable Gases (Syngas)

This is the primary fuel for the visible flame. The exact composition depends on the original material but often includes hydrogen, carbon monoxide, methane, and other volatile organic compounds. Their efficient burning is key to a "clean" and hot fire.

Liquids (Tars and Bio-oils)

Heavier molecules released during pyrolysis may not immediately burn. They can condense into tiny airborne droplets, which we see as the thick, dark part of smoke. If these tars coat a surface like a chimney, they create a highly flammable residue (creosote).

Solids (Char)

What remains after the volatile gases and liquids have been driven off is a carbon-rich solid residue called char. For wood, this product is charcoal. This char burns at a much slower rate through a different process called glowing combustion, which is what you see in the red embers of a fire after the flames have died down.

Understanding the Pitfalls and Implications

The nature of pyrolysis has direct consequences for efficiency and safety. Ignoring them means misunderstanding the fundamental risks and opportunities of combustion.

Incomplete Combustion and Smoke

Smoke is, in essence, a sign of inefficient combustion. It is composed of unburnt pyrolysis products—gases, tars, and solid carbon particles (soot). If the flammable gases don't get hot enough or can't mix with enough oxygen, they escape into the atmosphere unburnt, wasting potential energy and creating pollution.

The Inherent Safety Hazard

Pyrolysis continuously produces large volumes of flammable, and often explosive, gases. In an open campfire, these gases burn off as they are produced.

However, in an enclosed space like a room fire, these gases can accumulate near the ceiling. If a door or window is suddenly opened, the influx of oxygen can lead to a catastrophic ignition of this entire gas volume, an event known as a backdraft or flashover. This is why firefighters are so focused on ventilation control.

Pyrolysis as a Standalone Technology

Beyond its role in a fire, pyrolysis is harnessed as a powerful industrial process. By carefully heating waste like plastics, tires, or biomass in a reactor without oxygen, we can intentionally break them down into valuable outputs. This allows us to convert waste into syngas for electricity, bio-oil for fuel, and bio-char for agriculture, turning a disposal problem into a resource.

How to Apply This Knowledge

Understanding pyrolysis fundamentally changes how you approach any situation involving fire or high heat.

- If your primary focus is efficient energy generation: Your goal is to maximize the temperature and mixing of pyrolysis gases with oxygen to achieve complete combustion and release the most heat.

- If your primary focus is fire safety: You must respect that any fire is a pyrolysis gas generator; managing ventilation is critical to prevent the buildup of an explosive fuel-air mixture.

- If your primary focus is industrial material conversion: Your objective is to precisely control temperature and pressure in an oxygen-free environment to optimize the yield of desired products like bio-oil or bio-char.

Ultimately, knowing about pyrolysis shifts your perspective from seeing a fire as a simple event to a complex chemical process you can better manage and control.

Summary Table:

| Aspect | Description |

|---|---|

| Core Process | Chemical decomposition of a material by heat in the absence of oxygen. |

| Primary Role | The essential first step in combustion, producing flammable gases from solid/liquid fuels. |

| Key Products | Flammable gases (syngas), liquids (tars/bio-oils), and solids (char/charcoal). |

| Main Implications | Governs combustion efficiency, fire safety (risk of flashover), and industrial waste conversion. |

Ready to harness the power of controlled thermal processes in your lab?

At KINTEK, we specialize in high-quality lab equipment for precise heating and pyrolysis applications. Whether you are researching combustion, developing new materials, or converting waste into energy, our ovens, furnaces, and reactors are engineered for accuracy, safety, and reliability.

Let KINTEK be your partner in innovation. Contact us today to discuss how our solutions can enhance your research and development processes.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the role of corundum tubes in oxygen permeation testing? Ensure Integrity for Bi-doped Membranes