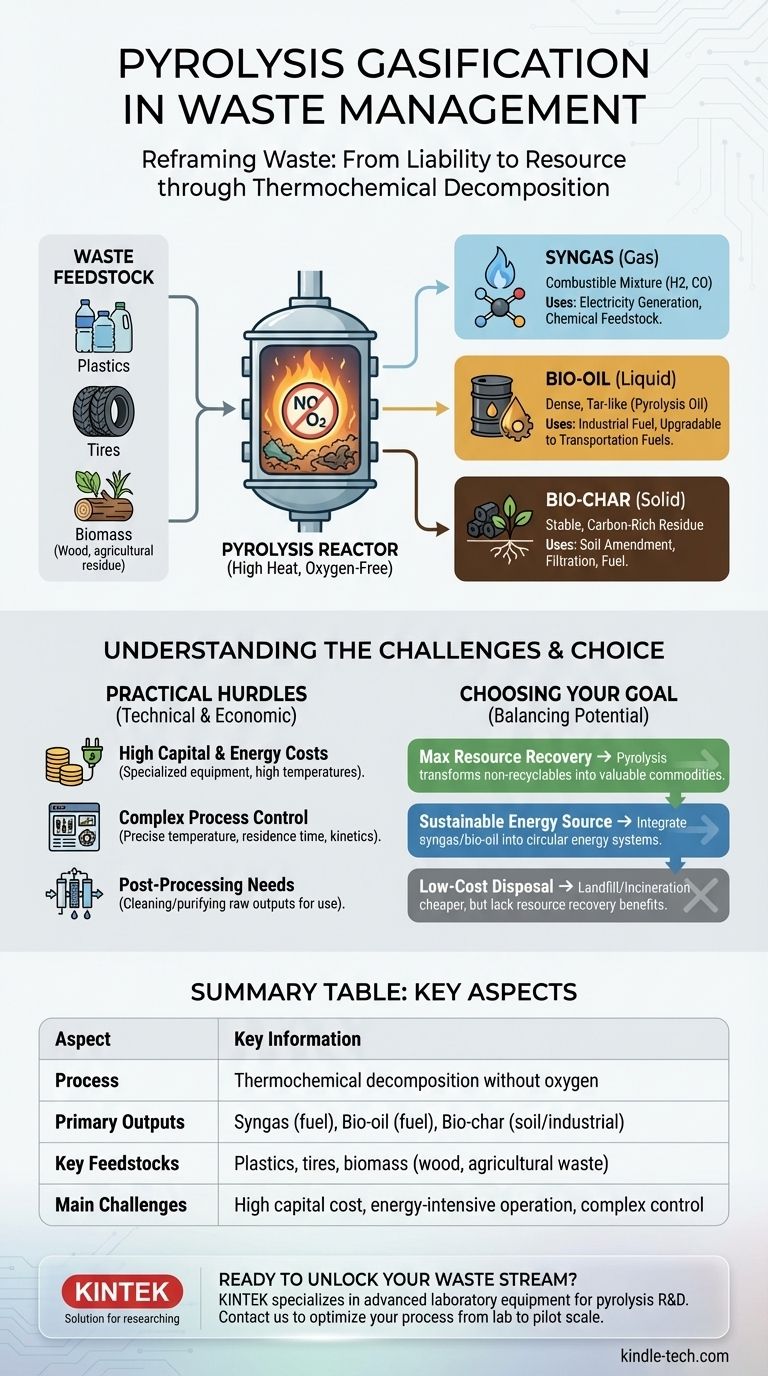

In the context of waste management, pyrolysis is a thermochemical process that converts solid waste into valuable products by heating it in a completely oxygen-free environment. Unlike incineration, which burns waste, pyrolysis causes the material to thermally decompose, breaking it down into a gas (syngas), a liquid (bio-oil), and a solid residue (bio-char).

The fundamental value of pyrolysis is its ability to reframe waste not as a disposal problem, but as a resource. It chemically transforms liabilities like plastics and biomass into assets such as fuel and soil amendments, though this conversion comes with significant technical and financial demands.

Deconstructing Waste: The Core Pyrolysis Process

Pyrolysis is a controlled, high-temperature reaction designed to recover the chemical energy locked within waste materials. It is fundamentally different from burning.

The Critical Condition: Heat Without Oxygen

The defining characteristic of pyrolysis is the absence of oxygen. Heating materials without oxygen prevents combustion.

Instead of burning and releasing energy as heat and light, the complex organic molecules in the waste break down into simpler, more valuable compounds.

The Three Primary Outputs

The process separates waste into three distinct and potentially useful product streams.

Syngas: A mixture of combustible gases, primarily hydrogen and carbon monoxide. It can be burned to generate electricity or serve as a feedstock for producing liquid fuels and chemicals.

Bio-oil: A dense, tar-like liquid also known as pyrolysis oil. After refining, it can be used as an industrial fuel or upgraded into transportation fuels.

Bio-char: A stable, carbon-rich solid residue. It can be used as a fuel, a soil amendment to improve fertility, or as a raw material for producing activated carbon for filtration.

Feedstock Versatility

Pyrolysis can handle a wide range of organic and carbon-based waste streams that are often difficult to manage.

This includes materials like plastics, used tires, and various forms of biomass (agricultural residue, wood waste), diverting them from landfills.

Understanding the Practical Challenges

While promising, pyrolysis is not a simple solution. It presents notable technical and economic hurdles that must be considered for any practical application.

High Capital and Energy Costs

Pyrolysis facilities require significant upfront investment in specialized reactors and processing equipment.

The process itself is also energy-intensive, as it requires maintaining very high temperatures, which can impact its overall energy balance and economic viability.

Complex Process Control

Efficiency hinges on precise control over process conditions. Factors like temperature, heating rate, and residence time (how long waste stays in the reactor) must be carefully managed.

The specific "kinetics," or reaction rates, change dramatically based on the type of waste being processed, demanding sophisticated operational oversight.

Post-Processing Requirements

The raw outputs of pyrolysis are rarely ready for immediate use. Syngas often needs cleaning, and bio-oil requires significant separation and purification before it can be used as a high-grade fuel.

Making the Right Choice for Your Goal

Adopting pyrolysis depends entirely on balancing its resource-recovery potential against its inherent complexity and cost.

- If your primary focus is maximum waste volume reduction and resource recovery: Pyrolysis is a powerful option for transforming non-recyclable waste streams into valuable commodities.

- If your primary focus is creating a sustainable energy source: The syngas and bio-oil produced can be integrated into energy systems, providing a more circular alternative to fossil fuels.

- If your primary focus is low-cost, simple waste disposal: Traditional landfilling or mass-burn incineration may be more economically feasible, though they lack the resource-recovery benefits of pyrolysis.

Ultimately, pyrolysis represents a sophisticated step towards a circular economy, offering a path to unlock value from materials previously considered worthless.

Summary Table:

| Aspect | Key Information |

|---|---|

| Process | Thermochemical decomposition without oxygen |

| Primary Outputs | Syngas (fuel), Bio-oil (fuel), Bio-char (soil/industrial) |

| Key Feedstocks | Plastics, tires, biomass (wood, agricultural waste) |

| Main Challenges | High capital cost, energy-intensive operation, complex process control |

Ready to unlock the value in your waste stream?

KINTEK specializes in advanced laboratory equipment and consumables for waste management research and development. Whether you are exploring pyrolysis process optimization, analyzing feedstock suitability, or testing the quality of syngas, bio-oil, and bio-char outputs, our precise and reliable solutions can support your project from the lab to pilot scale.

Contact us today to discuss how our equipment can help you develop efficient and effective pyrolysis solutions. Get in touch via our contact form to speak with an expert.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products