At its core, biomass pyrolysis is a thermochemical process that converts solid biomass, like wood or agricultural waste, into a liquid fuel intermediate. It works by rapidly heating the biomass to very high temperatures (500°C–700°C) in an environment completely free of oxygen, which causes the material to break down into vapor, gas, and a solid char. The valuable vapors are then cooled and condensed to form a dark, dense liquid known as bio-crude oil.

The central challenge with biomass is converting a bulky, solid material into a fungible, energy-dense liquid. Pyrolysis serves as the critical bridge in this process, creating an intermediate bio-crude that, while not a finished fuel, is the necessary precursor to upgraded biofuels and biochemicals.

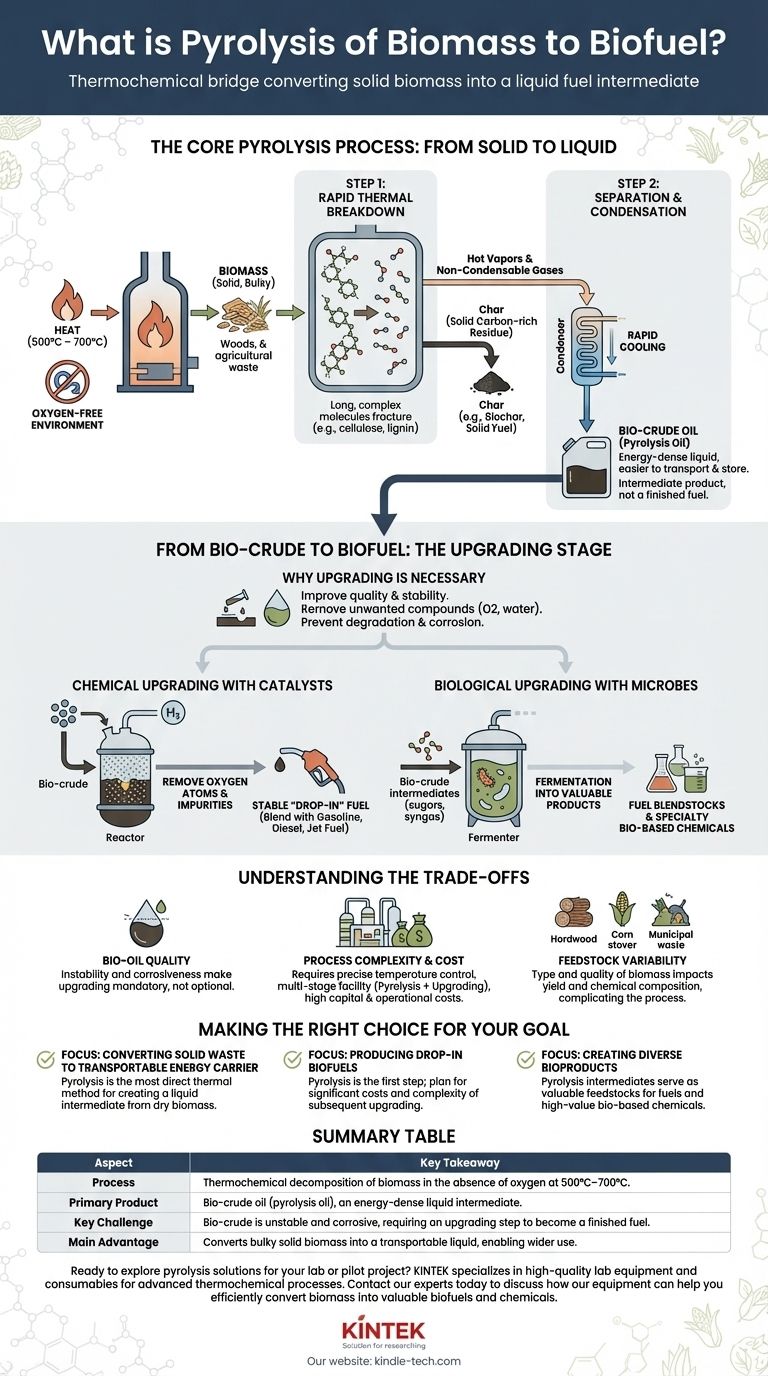

The Core Pyrolysis Process: From Solid to Liquid

The magic of pyrolysis lies in heating without burning. By removing oxygen, we ensure the biomass decomposes into new chemical components rather than simply combusting into ash and heat.

The Key Ingredients: Heat and No Oxygen

The process requires an oxygen-free (anaerobic) environment. This prevents the biomass from catching fire and forces it to undergo thermal decomposition.

This decomposition happens at extremely high temperatures, typically between 500°C and 700°C, ensuring the breakdown is rapid and complete.

Step 1: Rapid Thermal Breakdown

When subjected to intense heat in the absence of oxygen, the long, complex molecules within the biomass (like cellulose and lignin) fracture.

This breakdown creates a mix of smaller, volatile molecules that exist as a hot vapor, alongside some non-condensable gases and a solid carbon-rich residue called char.

Step 2: Separation and Condensation

The solid char is first separated from the hot gas and vapor stream. This char can be used as a soil amendment (biochar) or as a solid fuel.

The remaining hot vapors are then rapidly cooled. This condensation phase is what turns the gaseous intermediates into a liquid.

The Result: Bio-Crude Oil

The resulting liquid is bio-crude oil, sometimes called pyrolysis oil. It is an energy-dense liquid that is far easier to transport and store than the original solid biomass.

However, this bio-crude is not a finished product. It is an intermediate that must be processed further before it can be used as a conventional fuel.

From Bio-Crude to Biofuel: The Upgrading Stage

Raw bio-crude oil is often acidic, unstable, and contains high levels of oxygen and water, making it incompatible with standard engines and refining infrastructure. The "upgrading" stage is designed to solve this.

Why Upgrading is Necessary

The primary goal of upgrading is to improve the quality and stability of the bio-crude. This involves removing unwanted compounds to make the final product more like petroleum-based fuels.

Without upgrading, the bio-crude can degrade over time and is corrosive to standard storage tanks and pipelines.

Chemical Upgrading with Catalysts

The most common upgrading path uses catalysts—often in the presence of hydrogen—to process the bio-crude.

This chemical processing removes oxygen atoms and other impurities. The result is a more stable, hydrocarbon-rich "drop-in" fuel that can be blended with gasoline, diesel, or jet fuel.

Biological Upgrading with Microbes

An alternative pathway involves using microorganisms. In this approach, intermediates from the process, such as sugars or syngas, are fed to microbes.

These microorganisms ferment the material into valuable end products, which can include fuel blendstocks or specialty bio-based chemicals.

Understanding the Trade-offs

While promising, pyrolysis is a complex and energy-intensive technology with inherent challenges that must be considered for any practical application.

The Challenge of Bio-Oil Quality

The primary trade-off is the quality of the initial bio-crude. Its instability and corrosiveness mean that a costly and technically complex upgrading step is not optional, but mandatory for producing transportation fuels.

Process Complexity and Cost

A pyrolysis plant is more than just a furnace. It requires precise temperature control, systems for handling solids and gases, and a separate, sophisticated upgrading facility. This multi-stage reality adds significant capital and operational costs.

Feedstock Variability

The type and quality of the biomass feedstock—whether it's hardwood, corn stover, or municipal waste—directly impacts the yield and chemical composition of the bio-crude oil. This variability can complicate the process and require adjustments to maintain consistent output.

Making the Right Choice for Your Goal

Understanding the complete pathway from biomass to end-product is essential for evaluating the role of pyrolysis in a renewable energy strategy.

- If your primary focus is converting solid waste into a transportable energy carrier: Pyrolysis is the most direct thermal method for creating a liquid intermediate from dry biomass.

- If your primary focus is producing drop-in biofuels: Pyrolysis is only the first step; you must plan for the significant costs and complexity of the subsequent upgrading process.

- If your primary focus is creating a diverse range of bioproducts: The intermediates from pyrolysis can serve as valuable feedstocks for creating both fuels and high-value bio-based chemicals.

Ultimately, pyrolysis is a foundational technology for unlocking the chemical value stored within solid biomass.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Thermochemical decomposition of biomass in the absence of oxygen at 500°C–700°C. |

| Primary Product | Bio-crude oil (pyrolysis oil), an energy-dense liquid intermediate. |

| Key Challenge | Bio-crude is unstable and corrosive, requiring an upgrading step to become a finished fuel. |

| Main Advantage | Converts bulky solid biomass into a transportable liquid, enabling wider use. |

Ready to explore pyrolysis solutions for your lab or pilot project?

KINTEK specializes in high-quality lab equipment and consumables for advanced thermochemical processes. Whether you are researching biomass conversion, optimizing pyrolysis parameters, or scaling up biofuel production, our reactors, temperature control systems, and analytical tools are designed for precision and reliability.

Contact our experts today to discuss how our equipment can help you efficiently convert biomass into valuable biofuels and chemicals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs