In simple terms, pyrolysis rate is the speed at which a material thermally decomposes in an oxygen-free environment. It is a critical parameter that measures how quickly the feedstock (like biomass or plastic) breaks down when heated, typically expressed as the loss of mass over a specific unit of time (e.g., kilograms per hour) or as a function of temperature change.

Understanding pyrolysis rate isn't just about speed; it's about control. The rate at which you heat and decompose a material directly dictates the final output, determining whether you produce more solid bio-char, liquid bio-oil, or combustible syngas.

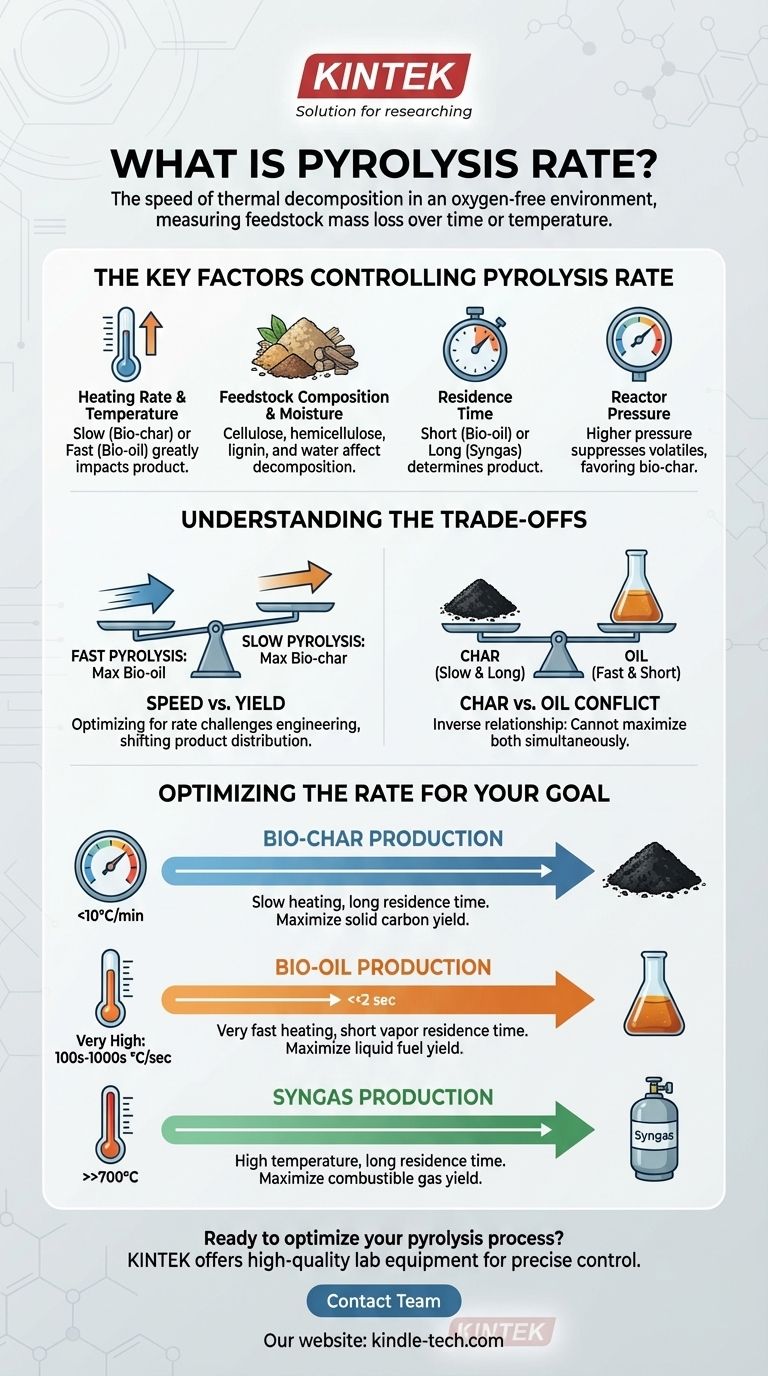

The Key Factors Controlling Pyrolysis Rate

The rate of pyrolysis is not a fixed property of a material but is instead highly sensitive to several process conditions. Properly controlling these factors is essential for achieving optimal performance and producing the desired end products.

### Heating Rate and Temperature

This is arguably the most influential factor. A slow heating rate (slow pyrolysis) allows complex molecules to break down and recombine into stable, carbon-rich structures, maximizing the yield of bio-char.

Conversely, a fast heating rate (fast pyrolysis) quickly breaks down the material into vapors and aerosols before they can form char. These vapors, when rapidly cooled, condense into a liquid known as bio-oil.

### Feedstock Composition and Moisture

The type of material being processed has a profound impact. Components like cellulose, hemicellulose, and lignin in biomass decompose at different temperatures and rates.

Additionally, the moisture content is critical. Energy must first be used to evaporate any water before the pyrolysis process can begin, effectively slowing the overall reaction rate and consuming thermal energy.

### Residence Time

This refers to how long the material (both the solid feedstock and the resulting vapors) remains in the high-temperature zone of the reactor.

A short residence time is crucial for fast pyrolysis to prevent the valuable vapors from "cracking" into lower-value permanent gases. A longer residence time at high temperatures will favor the production of syngas.

### Reactor Pressure

While often conducted at or near atmospheric pressure, changing the pressure can alter the rate. Higher pressures can suppress the release of volatile gases from the feedstock, changing the reaction pathways and often increasing the yield of bio-char.

Understanding the Trade-offs: Rate vs. Product Quality

Optimizing for a specific rate introduces a series of engineering and chemical trade-offs that must be carefully managed.

### The Speed vs. Yield Dilemma

A high pyrolysis rate (fast pyrolysis) is excellent for maximizing bio-oil production. However, achieving this requires very rapid heat transfer, which is a significant engineering challenge, especially at large scales.

Slower rates are easier to manage but fundamentally shift the product distribution away from liquids and towards solids.

### The Char vs. Oil Conflict

There is a direct and inverse relationship between char and oil yield. The conditions that favor a high rate of decomposition to produce oil (fast heating, short residence time) are precisely the opposite of what is needed to produce high-quality char (slow heating, long residence time).

You must choose which product stream is your priority, as you cannot simultaneously maximize both from a single process.

### Feedstock Inconsistency

A major operational challenge is that real-world feedstocks, like municipal solid waste or agricultural residues, are not uniform. Variations in composition, particle size, and moisture content can cause fluctuations in the pyrolysis rate, making it difficult to maintain consistent product quality without pre-treatment.

Optimizing the Rate for Your Goal

The ideal pyrolysis rate is not a single number; it is a parameter you adjust based on your desired outcome. Use these principles as your guide.

- If your primary focus is producing bio-char (for soil amendment or carbon sequestration): Employ a slow heating rate (typically less than 10°C/minute) and a long residence time to maximize solid yield.

- If your primary focus is maximizing bio-oil (for biofuel or chemical production): Use a very fast heating rate (hundreds or thousands of °C/second) with a short vapor residence time (typically <2 seconds).

- If your primary focus is generating syngas (for heat or power): Operate at very high temperatures (>700°C) with a longer residence time to encourage the secondary cracking of all vapors into simple gas molecules.

Ultimately, mastering the pyrolysis rate is mastering the transformation of a raw material into a valuable and specific end product.

Summary Table:

| Goal | Optimal Pyrolysis Rate Strategy | Key Product |

|---|---|---|

| Bio-Char Production | Slow heating rate (<10°C/min), long residence time | Maximizes solid carbon yield |

| Bio-Oil Production | Very fast heating rate (100s-1000s °C/sec), short vapor residence time (<2 sec) | Maximizes liquid fuel yield |

| Syngas Production | High temperature (>700°C), long residence time | Maximizes combustible gas yield |

Ready to optimize your pyrolysis process for maximum yield and efficiency?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored for pyrolysis research and development. Whether you are developing processes for bio-char, bio-oil, or syngas production, our reactors and analytical tools are designed to give you precise control over critical parameters like heating rate and residence time.

Let our expertise help you master your transformation process. Contact our team today to discuss your specific laboratory needs and discover the right KINTEK solutions for your project.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does the calcination process work? Master Thermal Decomposition for Material Purification

- What are the requirements for activated carbon? Matching Properties to Your Application for Success

- What are the problems of rotary kiln of cement and their remedies? Achieve Long-Term Reliability and Efficiency

- What is the impact of pyrolysis techniques on biochar characteristics application to soil? Tailor Biochar for Your Soil's Needs

- What are the different types of rotary kiln incinerators? Find the Right Design for Your Waste Stream

- What is the temperature range for biomass pyrolysis? Control Your Output of Biochar, Bio-oil, or Syngas

- How does a rotary kiln work? Unlock Continuous, High-Volume Thermal Processing

- What is the temperature range of a rotary kiln incinerator? Optimize Waste Destruction & Efficiency