The primary advantage of Chemical Vapor Deposition (CVD) over thermal oxidation is its profound versatility. While thermal oxidation is a highly specific process that converts a substrate material into its own oxide (like turning silicon into silicon dioxide), CVD is a deposition technique capable of creating thin films from a vast range of materials—including metals, ceramics, and alloys—onto virtually any suitable substrate.

The choice between CVD and oxidation is not about which is universally "better," but which is appropriate for the task. Oxidation is a specialized tool for creating a native oxide layer with exceptional quality, while CVD is a flexible platform for depositing a wide variety of non-native, high-purity films with precise control.

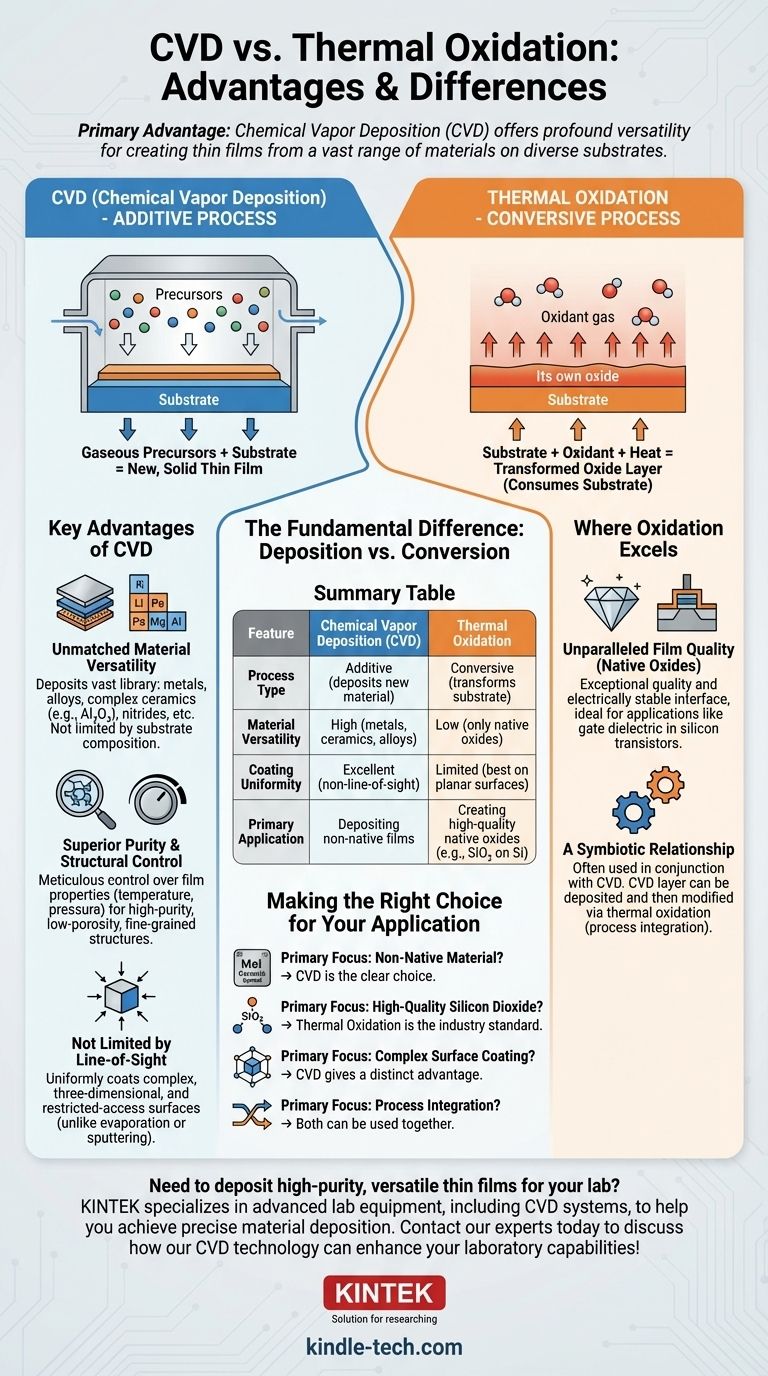

The Fundamental Difference: Deposition vs. Conversion

To understand the advantages, you must first grasp the core operational difference between these two processes. They do not accomplish the same goal.

CVD: Adding a New Layer

Chemical Vapor Deposition is an additive process. Gaseous chemical precursors are introduced into a reaction chamber where they decompose and react on a substrate's surface, forming a new, solid thin film.

The material being deposited is entirely different from the substrate it is being placed upon.

Oxidation: Transforming the Substrate

Thermal oxidation is a conversive process. The substrate (most commonly, a silicon wafer) is heated in an environment containing an oxidant (like oxygen or water vapor).

This process consumes a layer of the substrate itself to grow a film of its own oxide. It is not adding a new material, but rather transforming the existing one.

Key Advantages of the CVD Process

Because CVD is an additive process, it offers several capabilities that are impossible to achieve through oxidation.

Unmatched Material Versatility

CVD can deposit a vast library of materials. This includes pure metals, alloys, and complex ceramics like aluminum oxide (Al₂O₃), which offers excellent hardness and chemical stability.

Oxidation, by definition, can only create an oxide of the underlying material.

Superior Purity and Structural Control

The CVD process allows for meticulous control over film properties by adjusting parameters like temperature, pressure, and gas flow.

This enables the creation of high-purity films that can be single-crystal, polycrystalline, or amorphous, all with a fine-grained, low-porosity structure.

Not Limited by Line-of-Sight

Since CVD relies on gaseous reactants, it can uniformly coat complex, three-dimensional structures and restricted-access surfaces.

Processes like evaporation or sputtering (types of Physical Vapor Deposition, or PVD) are "line-of-sight" and struggle with non-flat topologies. Thermal oxidation is also generally performed on planar surfaces.

Understanding the Trade-offs and Limitations

No process is without its challenges. True objectivity requires acknowledging the potential downsides of CVD.

High Operating Temperatures

While some CVD processes operate at lower temperatures, many still require significant heat. This can introduce thermal instability or damage to sensitive substrates that cannot withstand the process temperatures.

Hazardous Precursors and By-products

The chemical precursors used in CVD are often highly toxic, flammable, and have high vapor pressures, making them dangerous to handle.

Furthermore, the chemical by-products of the reaction can be toxic and corrosive, requiring costly and problematic neutralization and disposal procedures.

Where Oxidation Excels: A Complementary Process

It is a mistake to view oxidation merely as a limited version of CVD. For its specific purpose, it is often the superior choice and can even be used in conjunction with CVD.

Unparalleled Film Quality for Native Oxides

For applications like creating the gate dielectric in a silicon transistor, thermal oxidation of silicon produces a silicon dioxide (SiO₂) layer with an exceptionally high-quality, electrically stable interface that is very difficult to replicate with deposited oxides.

A Symbiotic Relationship

CVD and oxidation are not always competitors; they are often partners in a larger fabrication flow.

A layer of polysilicon can be deposited using CVD and then subsequently be oxidized using a thermal process. This flexibility allows engineers to leverage the strengths of both methods in a single device.

Making the Right Choice for Your Application

Your decision depends entirely on the specific film you need to create and its intended function.

- If your primary focus is depositing a non-native material like a metal, nitride, or complex ceramic, CVD is the clear and often only choice.

- If your primary focus is creating the highest-quality silicon dioxide gate dielectric on silicon, thermal oxidation is the industry standard for this critical task.

- If your primary focus is coating a complex, three-dimensional surface uniformly, CVD's non-line-of-sight nature gives it a distinct advantage.

- If your primary focus is process integration, recognize that the two are often used together, such as depositing a layer with CVD and then modifying it with oxidation.

By understanding the core function of each—deposition versus conversion—you can select the precise tool needed to achieve your material engineering goals.

Summary Table:

| Feature | Chemical Vapor Deposition (CVD) | Thermal Oxidation |

|---|---|---|

| Process Type | Additive (deposits new material) | Conversive (transforms substrate) |

| Material Versatility | High (metals, ceramics, alloys) | Low (only native oxides) |

| Coating Uniformity | Excellent (non-line-of-sight) | Limited (best on planar surfaces) |

| Primary Application | Depositing non-native films | Creating high-quality native oxides (e.g., SiO₂ on Si) |

Need to deposit high-purity, versatile thin films for your lab?

KINTEK specializes in advanced lab equipment, including CVD systems, to help you achieve precise material deposition on complex substrates. Whether you're working with metals, ceramics, or alloys, our solutions provide the control and uniformity your research demands.

Contact our experts today to discuss how our CVD technology can enhance your laboratory capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition