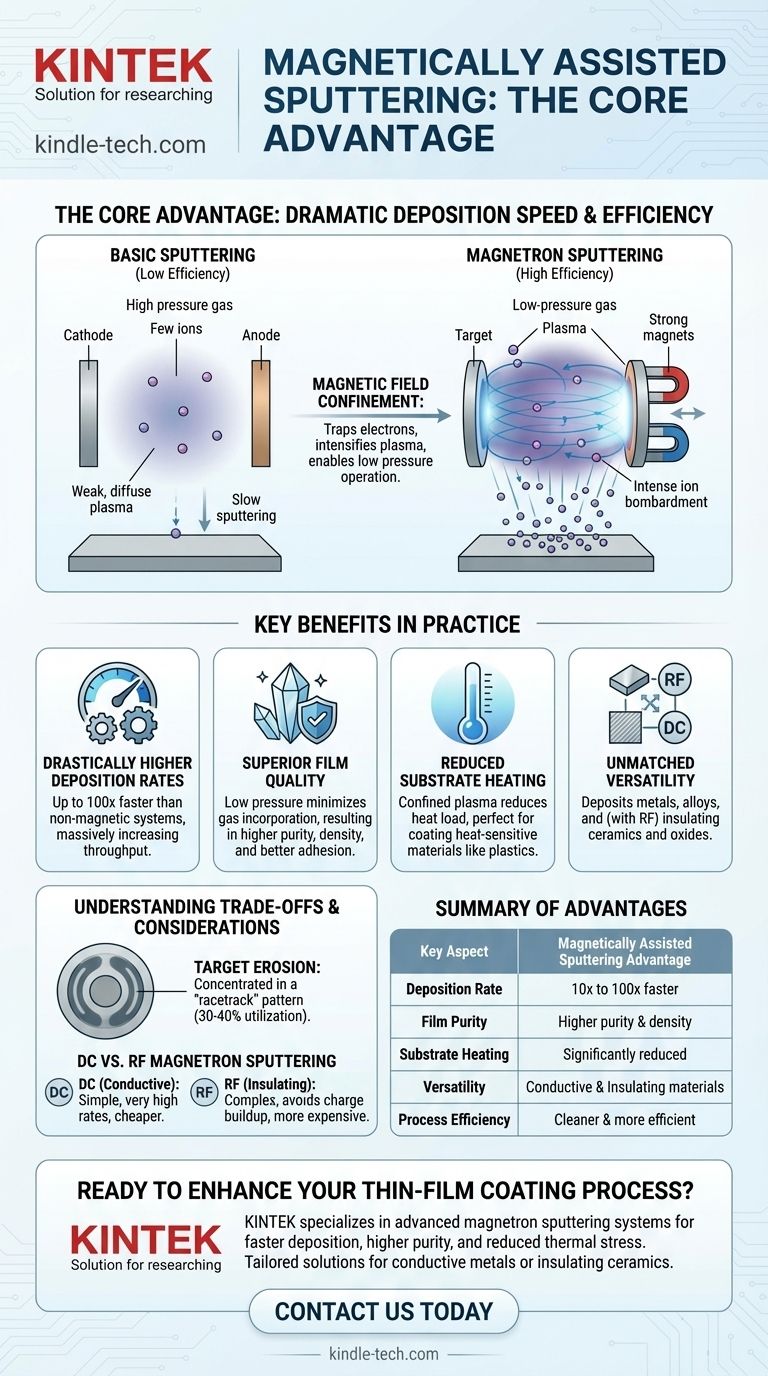

The core advantage of magnetically assisted sputtering is a dramatic increase in deposition speed and process efficiency. By using magnetic fields to trap electrons near the target material, a much denser plasma is created, which intensifies ion bombardment and sputters material away far more rapidly than non-magnetic methods, all while operating at a lower, cleaner pressure.

Magnetron sputtering isn't a fundamentally different process, but a critical enhancement. It uses magnetic fields to solve the core inefficiency of basic sputtering, resulting in significantly faster deposition, higher-purity films, and lower substrate heating, making it the dominant method for industrial thin-film applications.

How Magnetic Fields Revolutionize Sputtering

To understand the advantage of adding magnets, we must first recognize the limitation of basic sputtering. The enhancement addresses the fundamental inefficiency of plasma generation.

The Problem with Basic Sputtering

In a simple sputtering system, a high voltage is applied in a low-pressure gas (usually Argon). This creates a plasma, but it is weak and diffuse.

To generate enough ions to sputter the target at a reasonable rate, the gas pressure must be relatively high. This high pressure leads to unwanted collisions between the sputtered atoms and gas atoms, reducing deposition efficiency and potentially contaminating the film.

The Magnetic Solution: Plasma Confinement

Magnetron sputtering places strong magnets behind the target material. These magnets create a field that traps electrons in a confined region near the surface of the target.

This magnetic trap forces the electrons into a spiral path, dramatically increasing the distance they travel before reaching an anode. This confinement is the key to the entire process.

A Cascade of Efficiency Gains

Because the electrons are trapped, their probability of colliding with and ionizing neutral argon atoms increases by orders of magnitude.

This creates a self-sustaining, dense plasma located directly in front of the target. This dense cloud of positive argon ions is then accelerated into the target, resulting in a much higher and more focused ion bombardment.

The Benefit of Low-Pressure Operation

Since the plasma is generated so efficiently by the magnetic field, the overall gas pressure in the chamber can be significantly reduced.

Lower pressure means there are fewer gas atoms for the sputtered material to collide with on its journey to the substrate. This results in a more direct "line-of-sight" deposition, leading to denser, purer films with better adhesion.

Key Benefits in Practice

The underlying physics translates directly into tangible, practical advantages that have made magnetron sputtering an industrial standard.

Drastically Higher Deposition Rates

The most significant benefit is speed. Due to the intense and focused ion bombardment, deposition rates can be ten to one hundred times higher than in non-magnetic systems, massively increasing manufacturing throughput.

Superior Film Quality

The ability to operate at low pressures is critical for quality. It minimizes the chance of argon gas being incorporated into the growing film, resulting in higher film purity and density. The higher energy of the arriving atoms also promotes better adhesion to the substrate.

Reduced Substrate Heating

Because the dense plasma is confined to the target area, the substrate is exposed to less direct plasma bombardment and fewer stray electrons. This significantly reduces the heat load, making it possible to coat heat-sensitive materials like plastics without causing damage.

Unmatched Versatility

Magnetron sputtering can be used to deposit virtually any material, including metals, alloys, and compounds. When paired with a Radio Frequency (RF) power supply, it can even sputter electrically insulating materials like ceramics and oxides, which is impossible with standard DC sputtering.

Understanding the Trade-offs and Considerations

While powerful, magnetron sputtering is not without its specific operational characteristics and limitations.

Target Erosion and Utilization

The magnetic field that confines the plasma is not uniform across the target face. This causes the sputtering to be concentrated in a specific "racetrack" pattern.

This non-uniform erosion means that material in the center and at the edges of the target is underutilized, typically leading to a target utilization of only 30-40% before it must be replaced.

DC vs. RF Magnetron Sputtering

The type of power supply used is a critical distinction.

- DC (Direct Current): Simpler, cheaper, and offers very high rates, but only works for electrically conductive target materials.

- RF (Radio Frequency): More complex and expensive, but necessary for insulating (dielectric) materials. It alternates the voltage rapidly to prevent a positive charge from building up on the target surface, which would otherwise halt the sputtering process.

Making the Right Choice for Your Goal

Selecting the correct sputtering approach depends entirely on your material and desired outcome.

- If your primary focus is speed and throughput for conductive materials: DC magnetron sputtering is the industry standard for its unmatched deposition rates.

- If your primary focus is depositing high-quality insulating films (like ceramics or oxides): RF magnetron sputtering is the essential choice to achieve a stable and effective process.

- If your primary focus is coating heat-sensitive substrates (like polymers): Magnetron sputtering's ability to reduce substrate heating makes it far superior to non-magnetic or evaporative techniques.

- If your primary focus is achieving the highest possible film purity: The low-pressure operation of any magnetron system is a significant advantage, as it minimizes gas incorporation into the growing film.

Ultimately, adding a magnetic field transforms sputtering from a basic deposition method into a highly controllable, efficient, and versatile tool for modern engineering.

Summary Table:

| Key Aspect | Magnetically Assisted Sputtering Advantage |

|---|---|

| Deposition Rate | 10x to 100x faster than non-magnetic methods |

| Film Purity | Higher purity and density due to low-pressure operation |

| Substrate Heating | Significantly reduced, ideal for heat-sensitive materials |

| Versatility | Capable of depositing metals, alloys, and insulating ceramics |

| Process Efficiency | Dense plasma confinement enables cleaner, more efficient deposition |

Ready to Enhance Your Thin-Film Coating Process?

KINTEK specializes in advanced lab equipment, including magnetron sputtering systems designed to deliver faster deposition speeds, higher film purity, and reduced thermal stress on sensitive substrates. Whether you're working with conductive metals or insulating ceramics, our solutions are tailored to meet your laboratory's specific needs.

Contact us today to discover how our sputtering technology can optimize your research and production outcomes.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is the meaning of deposition of vapor? A Guide to Thin-Film Coating Technologies

- What are the advantages of ALD? Achieve Atomic-Level Precision for Superior Thin Films

- Which one is better, HPHT or CVD? Choosing the Right Lab-Grown Diamond for Your Priorities

- What are the principles of CVD process? Master High-Purity Thin Film Deposition

- What is the role of DLI-MOCVD in nuclear cladding tube coatings? Achieve Uniform Inner Surface Deposition

- What are the chemical Vapour deposition process parameters? Master CVD for Superior Thin Films

- What are the steps of the ALD process? Achieve Atomic-Level Precision for Your Thin Films

- What are the two main categories of modern CVD processes? Comparing LPCVD and UHVCVD for Precision Film Growth