The primary advantage of PVD over CVD is its significantly lower process temperature. This allows Physical Vapor Deposition (PVD) to coat heat-sensitive materials without altering their fundamental properties or causing distortion, while also preserving the part's original surface finish.

The choice between PVD and CVD is not about finding a universally "better" technology, but about aligning the process with your specific material, part geometry, and desired outcome. PVD's physical process is ideal for lower-temperature applications, while CVD's chemical process excels at coating complex, non-line-of-sight surfaces.

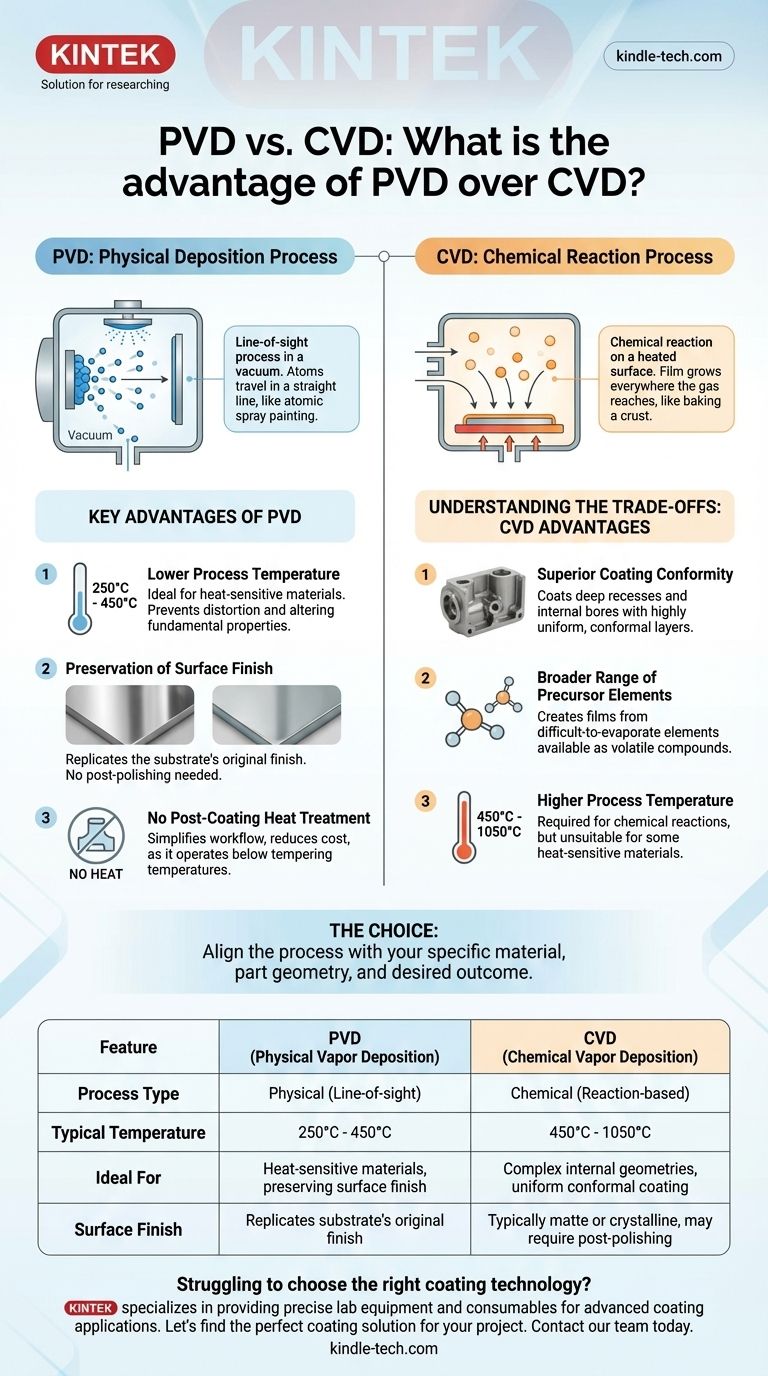

The Fundamental Process Distinction

To understand the advantages of each method, we must first look at how they work. The core difference between PVD and CVD dictates every other performance characteristic, from temperature to surface finish.

PVD: A Physical Deposition Process

PVD is a line-of-sight process that occurs in a vacuum. A solid source material is vaporized through physical means (like sputtering with ions or evaporating with heat), and the resulting atoms travel in a straight line to deposit onto the substrate.

Think of it as an atomic-level form of spray painting. The "paint" (the vaporized atoms) can only stick to the surfaces it can directly "see" from the source.

CVD: A Chemical Reaction Process

Chemical Vapor Deposition (CVD), by contrast, relies on a chemical reaction. Gaseous precursor chemicals are introduced into a chamber where they react on a heated substrate surface, forming a solid film.

This is more like baking a crust onto a loaf of bread. The heat of the substrate itself drives the reaction, causing the film to "grow" directly on the surface wherever the gas can reach.

Key Advantages of PVD in Practice

The physical nature of PVD leads to several distinct operational advantages.

Lower Process Temperature

PVD processes typically operate at much lower temperatures, generally between 250°C and 450°C.

In contrast, CVD requires significantly higher temperatures—often between 450°C and 1050°C—to initiate the necessary chemical reactions. This heat makes CVD unsuitable for materials like hardened tool steels, aluminum, or polymers that would be softened, damaged, or warped.

Preservation of Surface Finish

PVD faithfully replicates the substrate's original surface finish. If you coat a highly polished part with PVD, the result will be a highly polished coating.

CVD, due to its chemical growth process, typically results in a matte or crystalline finish. Achieving a polished look with a CVD-coated part requires expensive and time-consuming post-processing.

No Post-Coating Heat Treatment

Because PVD operates below the tempering temperature of most steels, parts do not require subsequent heat treatment to restore their hardness or mechanical properties. This simplifies the manufacturing workflow and reduces cost.

Understanding the Trade-offs: When to Consider CVD

While PVD's low temperature is a major advantage, it is not the right solution for every problem. CVD's unique characteristics make it superior for certain applications.

The Line-of-Sight Limitation

The primary drawback of PVD is that it is a line-of-sight process. It cannot effectively coat deep recesses, internal bores, or the hidden surfaces of complex parts.

Superior Coating Conformity

CVD excels where PVD fails. Because it uses a gas that can flow into any open space, CVD can deposit a highly uniform (conformal) coating on all surfaces of a complex part, both internal and external.

Broader Range of Precursor Elements

CVD can create films from elements that are difficult to evaporate or sputter but are readily available as volatile chemical compounds. This opens up a different range of possible coating chemistries compared to PVD.

Making the Right Choice for Your Goal

Selecting the correct technology requires a clear understanding of your primary objective.

- If your primary focus is coating heat-sensitive materials: PVD is the clear choice due to its low operating temperature, preventing damage to substrates like hardened steels or aluminum.

- If your primary focus is preserving a high-polish or decorative finish: PVD is superior because it directly replicates the original surface texture without needing post-polishing.

- If your primary focus is coating complex internal geometries: CVD is the only viable option, as its gaseous precursors can reach all surfaces, unlike PVD's line-of-sight deposition.

- If your primary focus is achieving the most uniform coating on an intricate part: CVD's ability to create highly conformal layers on all exposed surfaces makes it the better technology.

Understanding these core differences empowers you to select the precise coating technology that aligns perfectly with your material, geometry, and performance requirements.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (Line-of-sight) | Chemical (Reaction-based) |

| Typical Temperature | 250°C - 450°C | 450°C - 1050°C |

| Ideal For | Heat-sensitive materials, preserving surface finish | Complex internal geometries, uniform conformal coating |

| Surface Finish | Replicates substrate's original finish | Typically matte or crystalline, may require post-polishing |

Struggling to choose the right coating technology for your lab equipment or components? The choice between PVD and CVD is critical for protecting your materials and achieving the desired performance. KINTEK specializes in providing the precise lab equipment and consumables you need for advanced coating applications. Our experts can help you navigate these complex decisions to ensure optimal results for your specific materials and part geometries.

Let's find the perfect coating solution for your project. Contact our team today via our simple form to discuss your requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications