The primary advantages of thermal evaporation over sputtering are its significantly higher deposition rates and its lower equipment cost and complexity. This makes it a faster and more cost-effective method for depositing thin films, especially in high-volume production environments.

The choice between thermal evaporation and sputtering is not about which method is universally better, but which one aligns with your specific priorities. Thermal evaporation excels in speed and cost-efficiency, while sputtering offers superior film quality, adhesion, and material versatility.

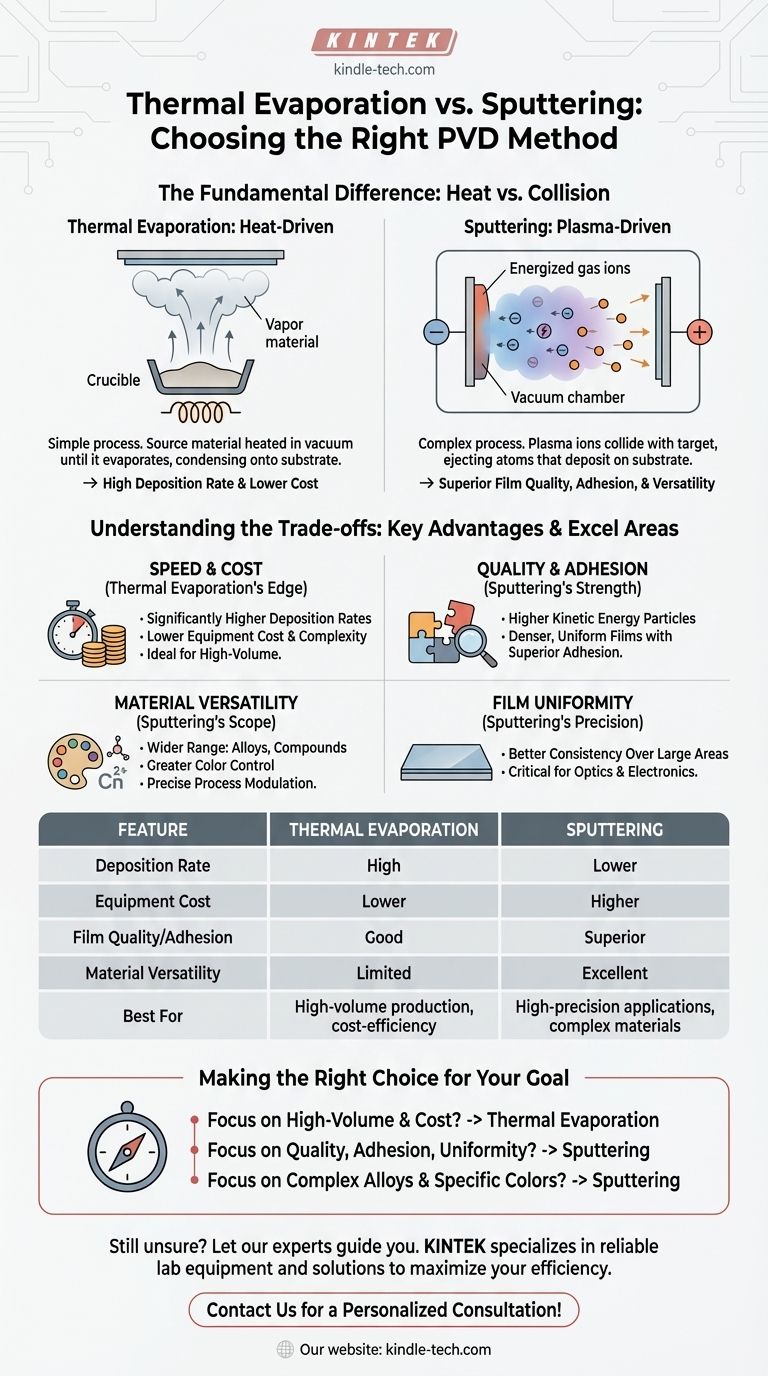

The Fundamental Difference: Heat vs. Collision

The advantages and disadvantages of each method stem directly from their underlying physical mechanisms.

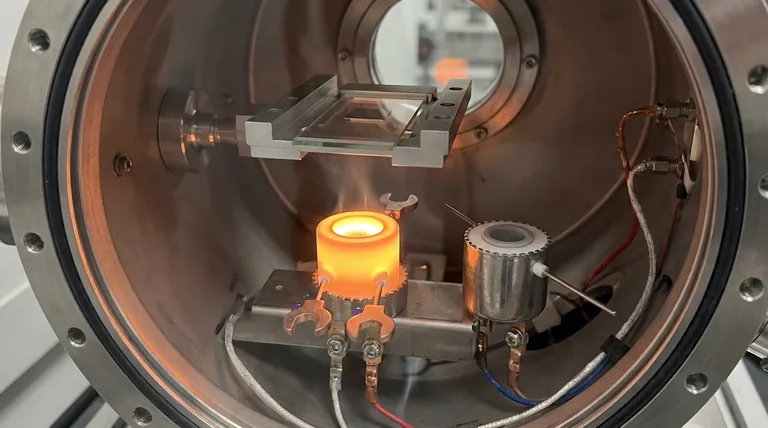

How Thermal Evaporation Works

Thermal evaporation is a relatively straightforward process. A source material, typically in a crucible, is heated in a vacuum until it evaporates, creating a robust vapor stream that condenses on a substrate to form a thin film.

How Sputtering Works

Sputtering is a more complex plasma-based process. A high voltage is applied to a target made of the coating material in a vacuum chamber filled with an inert gas like argon. This creates a plasma, and the positively charged gas ions are accelerated into the target, knocking off atoms or small clusters of atoms that then deposit onto the substrate.

Key Advantages of Thermal Evaporation

The simplicity of the thermal evaporation process leads to its main benefits.

Superior Deposition Speed

Because thermal evaporation generates a dense vapor stream, it can deposit material much more quickly than sputtering. This makes it highly efficient for applications where short cycle times and high throughput are critical.

Lower Cost and Simplicity

The equipment required for thermal evaporation is generally less complex and therefore less expensive than a sputtering system. It does not require high-voltage power supplies or the intricate gas and pressure controls needed to maintain a stable plasma.

Understanding the Trade-offs: When Sputtering Excels

While thermal evaporation is faster and cheaper, sputtering is often chosen for applications where film characteristics are paramount.

Film Quality and Adhesion

Sputtering ejects particles with higher kinetic energy. This results in films that are typically denser, more uniform, and have significantly better adhesion to the substrate compared to evaporated films.

Material and Color Versatility

Sputtering can deposit a wider range of materials, including alloys and compounds, with greater control. It also offers superior color versatility through process modulation, whereas thermal evaporation is often limited to the natural color of the source material.

Film Uniformity

The sputtering process generally provides a more uniform and controlled deposition over a larger area. The ejected atoms have a wider distribution, leading to better film consistency, which is critical for precision applications like optics and electronics.

Making the Right Choice for Your Goal

Selecting the correct physical vapor deposition (PVD) method requires a clear understanding of your project's end goal.

- If your primary focus is high-volume production and cost-efficiency: Thermal evaporation is the clear choice due to its high deposition rates and lower system complexity.

- If your primary focus is superior film quality, adhesion, and uniformity: Sputtering is the ideal method, providing the precision required for high-performance applications.

- If your primary focus is working with complex alloys or achieving specific colors: Sputtering offers far greater control and versatility over the final film properties.

Ultimately, understanding the core trade-off between the speed of evaporation and the quality of sputtering empowers you to select the most effective technology for your specific needs.

Summary Table:

| Feature | Thermal Evaporation | Sputtering |

|---|---|---|

| Deposition Rate | High | Lower |

| Equipment Cost | Lower | Higher |

| Film Quality/Adhesion | Good | Superior |

| Material Versatility | Limited | Excellent |

| Best For | High-volume production, cost-efficiency | High-precision applications, complex materials |

Still unsure which PVD method is right for your lab? The choice between thermal evaporation and sputtering depends entirely on your specific production goals and quality requirements. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance and reliable solutions.

Let our experts help you select the perfect thin film deposition system to maximize your efficiency and achieve your desired film properties. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

People Also Ask

- What is the deposition of thin films? A Guide to Coating Technology for Modern Devices

- What is the difference between thermal and electron beam evaporation? Unlock the Right Thin Film Deposition Method

- What is the vaporization of zinc? A Critical Safety & Quality Challenge in Welding

- Why e-beam evaporation is developed for thin film processing? Unlock High-Purity Films for Advanced Applications

- What is the mechanism of evaporation? Unlock High-Purity Thin Film Deposition

- What is the key trade-off when loading material for evaporation? Balancing Capacity vs. Stability

- What is step coverage in thermal evaporation? Avoid Device Failure with the Right Deposition Method

- What are the disadvantages of thermal evaporation method? Key Limitations in Purity and Performance