The primary benefit of PECVD is its ability to deposit high-quality, uniform thin films at significantly lower temperatures than conventional Chemical Vapor Deposition (CVD). This is achieved by using plasma to supply the energy needed for chemical reactions, rather than relying solely on high heat. This fundamental difference makes PECVD ideal for coating materials that cannot withstand thermal stress.

The core advantage of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is that it decouples the reaction energy from thermal energy. By using an electric field to create plasma, it enables the growth of dense, high-performance films on temperature-sensitive substrates without causing damage.

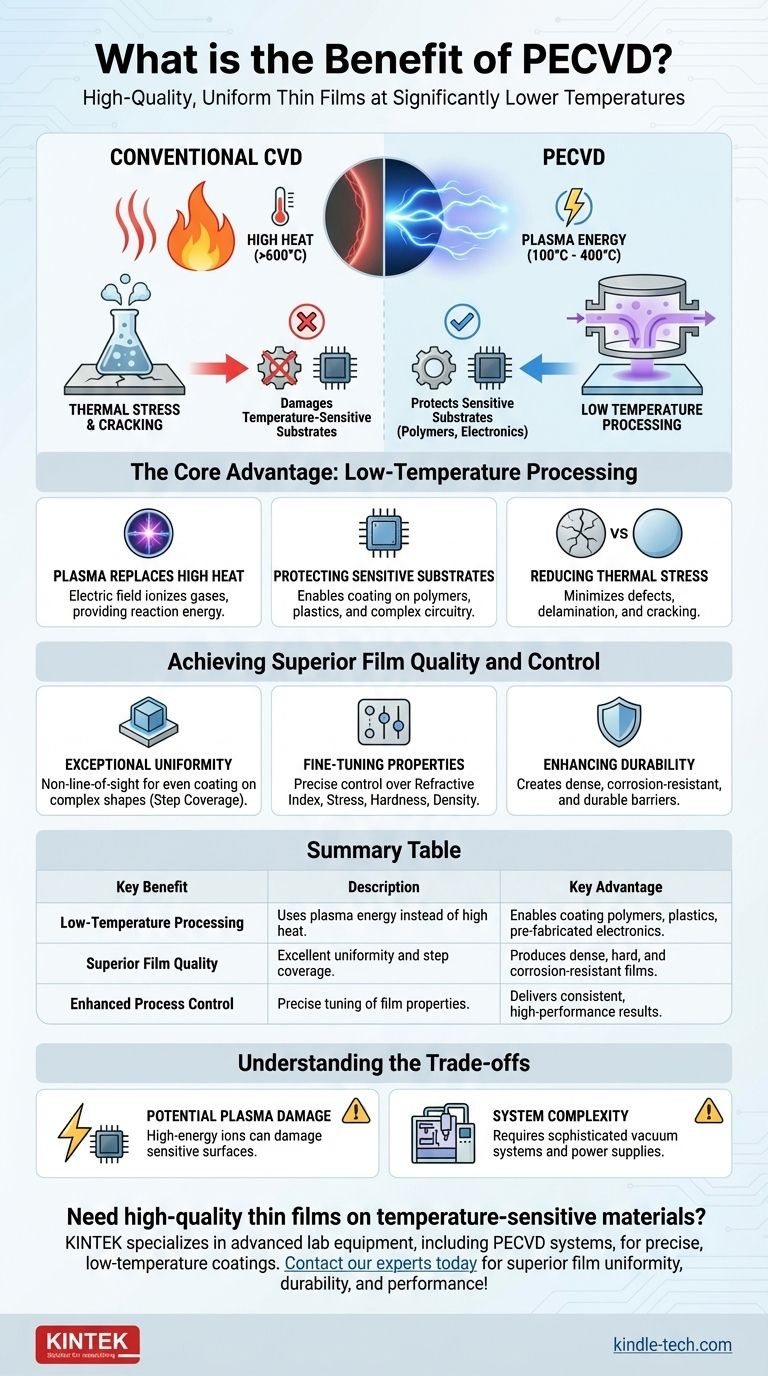

The Core Advantage: Low-Temperature Processing

The most significant distinction of PECVD is its low-temperature operation. This capability unlocks applications that are impossible with traditional, high-temperature thermal CVD.

How Plasma Replaces High Heat

In conventional CVD, precursor gases must be heated to very high temperatures (often >600°C) to gain enough energy to react and form a film on the substrate. PECVD uses an electric field to ionize these gases, creating a highly energetic plasma. This plasma provides the activation energy for the reaction, allowing the process to run at much lower temperatures, typically between 100°C and 400°C.

Protecting Sensitive Substrates

This lower temperature is critical when working with materials that have a low melting point or are already integrated with other components. For example, you can deposit films on polymers, plastics, or fully fabricated semiconductor wafers with complex circuitry without damaging the underlying structures.

Reducing Thermal Stress and Cracking

High temperatures introduce significant thermal stress as materials expand and contract. This stress can lead to defects, delamination, or cracking in the deposited film. By operating at lower temperatures, PECVD dramatically reduces this risk, resulting in higher quality, more reliable layers.

Achieving Superior Film Quality and Control

Beyond its low-temperature advantage, PECVD provides a high degree of control over the final product, leading to superior and more consistent films.

Exceptional Uniformity and Step Coverage

Like other CVD methods, PECVD is a non-line-of-sight process. This means the precursor gases can flow around and coat complex, three-dimensional shapes evenly. The result is excellent step coverage and highly uniform film thickness across the entire surface of the substrate.

Fine-Tuning Material Properties

The use of plasma allows for precise control over the deposition process. By adjusting parameters like gas flow, pressure, and plasma power, operators can fine-tune critical material properties of the film, such as its refractive index, internal stress, hardness, and density.

Enhancing Durability and Performance

The resulting films are dense, adhere well to the substrate, and provide powerful functional benefits. PECVD coatings are widely used to create corrosion-resistant barriers and to increase the surface rigidness and durability of a product.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. The use of plasma, which is its primary advantage, also introduces specific considerations that may not be present in simpler thermal processes.

Potential for Plasma-Induced Damage

The high-energy ions within the plasma can sometimes cause physical or electrical damage to the substrate surface. This is a critical factor to manage in applications like semiconductor manufacturing, where the underlying electronic devices are extremely sensitive.

Film Chemistry Complexity

Plasma chemistry can be very complex. Films deposited via PECVD can sometimes incorporate elements from the precursor gases, such as hydrogen, which may be undesirable for certain applications. This requires careful process tuning and characterization.

System and Process Complexity

PECVD systems are generally more complex and expensive than standard thermal CVD reactors due to the need for RF power supplies, matching networks, and sophisticated vacuum systems. This can translate to higher initial capital investment and maintenance requirements.

Is PECVD the Right Choice for Your Application?

Choosing the correct deposition method depends entirely on your substrate, desired film properties, and operational constraints.

- If your primary focus is depositing on heat-sensitive materials: PECVD is the superior choice over thermal CVD due to its fundamentally low-temperature operation.

- If your primary focus is achieving specific optical or mechanical properties: PECVD offers exceptional control over film characteristics like refractive index, stress, and hardness.

- If your primary focus is coating complex, non-planar surfaces: The non-line-of-sight nature of PECVD ensures excellent uniformity and step coverage.

- If your primary focus is absolute film purity with minimal contamination: You must carefully consider and mitigate the potential for ion damage and hydrogen incorporation inherent in the plasma process.

Ultimately, PECVD empowers engineers and scientists to create high-performance thin films in situations where heat would be a destructive barrier.

Summary Table:

| Key Benefit | Description | Key Advantage |

|---|---|---|

| Low-Temperature Processing | Uses plasma energy instead of high heat for deposition. | Enables coating of polymers, plastics, and pre-fabricated electronics. |

| Superior Film Quality | Excellent uniformity and step coverage on complex shapes. | Produces dense, hard, and corrosion-resistant films. |

| Enhanced Process Control | Precise tuning of film properties like stress and refractive index. | Delivers consistent, high-performance results. |

Need to deposit high-quality thin films on temperature-sensitive materials? KINTEK specializes in advanced lab equipment, including PECVD systems, to help you achieve precise, low-temperature coatings for your most demanding applications. Our expertise ensures you get the right solution for superior film uniformity, durability, and performance. Contact our experts today to discuss how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition