In short, biochar is the solid, carbon-rich material that remains after biomass is heated in an oxygen-free environment through a process called pyrolysis. Unlike burning, which produces ash, pyrolysis thermally decomposes organic matter like wood, crop waste, or manure, fundamentally transforming it into a stable, porous carbon structure.

Biochar is not a byproduct of pyrolysis; it is a co-product. Its value lies in the fact that its properties—from porosity to nutrient content—can be precisely engineered by controlling the pyrolysis conditions, turning a waste stream into a powerful tool for soil enhancement and carbon sequestration.

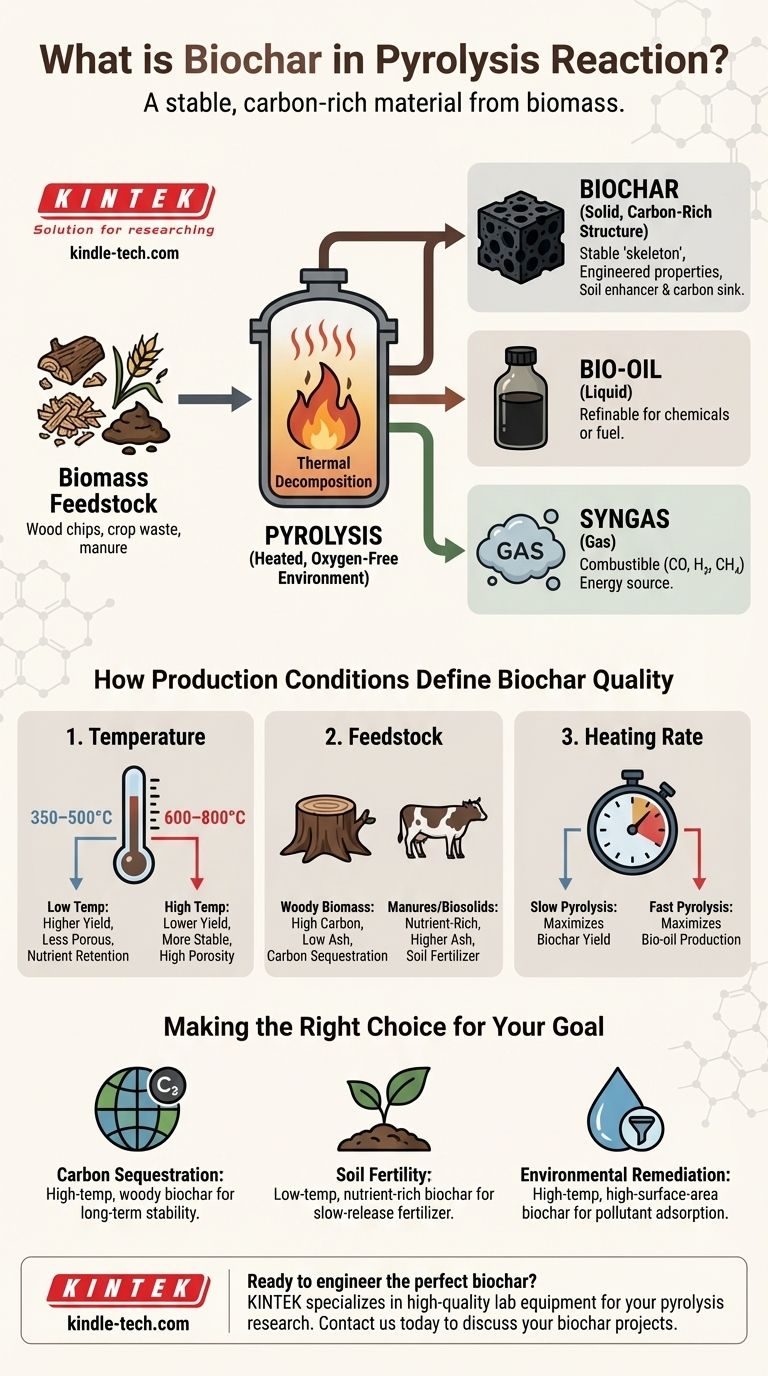

Deconstructing the Pyrolysis Reaction

To understand biochar, you must first understand the process that creates it. Pyrolysis is a thermochemical reaction that fundamentally alters the structure of organic material.

What is Pyrolysis?

Pyrolysis is the heating of an organic material, known as feedstock, in the near-total absence of oxygen. Without oxygen, the material cannot combust (burn). Instead of turning to ash and smoke, it breaks down into a mixture of solids, liquids, and gases.

Think of it as high-temperature cooking in a sealed container. The process "bakes" the carbon into a stable form rather than burning it away.

The Three Key Products

The pyrolysis of biomass yields three distinct products, and the ratio of these products can be manipulated:

- Biochar (Solid): The carbonaceous solid residue. This is the stable "skeleton" of the original biomass.

- Bio-oil (Liquid): A dark brown liquid, also known as pyrolysis oil. It's a complex mix of oxygenated organic compounds that can be refined into chemicals or used as a fuel.

- Syngas (Gas): A mixture of combustible gases, primarily carbon monoxide (CO), hydrogen (H₂), methane (CH₄), and carbon dioxide (CO₂). This gas can be captured and burned to generate heat or electricity, often to power the pyrolysis process itself.

How Production Conditions Define Biochar Quality

The term "biochar" describes a wide range of materials. Its specific characteristics are not accidental; they are a direct result of the feedstock used and the precise conditions of the pyrolysis reaction.

The Critical Role of Temperature

Temperature is the most influential variable in determining biochar's final properties.

- Low-Temperature Pyrolysis (350–500°C): This produces a higher yield of biochar. The resulting material has more residual volatile compounds and is less porous, but it often retains more nutrients from the original feedstock.

- High-Temperature Pyrolysis (600–800°C): This results in a lower yield of biochar but creates a product that is more stable, has a higher percentage of fixed carbon, and possesses a much greater surface area and porosity.

The Influence of Feedstock

The material you start with dictates the biochar's innate chemical composition.

- Woody Biomass (e.g., wood chips): Produces a high-carbon, low-ash biochar that is structurally robust. It is ideal for carbon sequestration and improving soil structure.

- Manures and Biosolids: Produce a lower-carbon, higher-ash biochar that is rich in nutrients like phosphorus and potassium. This type is better suited as a slow-release fertilizer.

The Impact of Heating Rate

How quickly the feedstock is heated to the target temperature also shifts the output.

- Slow Pyrolysis: A slow heating rate maximizes the production of biochar. This is the preferred method when biochar is the primary desired product.

- Fast Pyrolysis: A very rapid heating rate cracks the organic vapors into smaller molecules before they can polymerize, maximizing the yield of bio-oil.

Understanding the Trade-offs and Key Considerations

While biochar holds immense promise, a clear-eyed, objective view requires acknowledging its complexities and potential pitfalls.

Not All Biochar is Created Equal

The single most common mistake is treating all biochar as a uniform product. Using a high-pH biochar from wood on an already alkaline soil can harm crop growth. Similarly, a low-nutrient biochar will not serve as an effective fertilizer. The application must match the specific properties of the biochar.

Potential for Contaminant Concentration

Pyrolysis does not destroy heavy metals like lead or cadmium. If the initial feedstock (such as municipal sludge or industrial waste) is contaminated, these toxins can become concentrated in the resulting biochar, making it unsuitable and potentially hazardous for agricultural use.

Energy and Economic Viability

The pyrolysis process is energy-intensive. A sustainable operation must be designed to use the syngas and bio-oil it co-produces to power itself, creating a closed-loop system. The high capital cost of pyrolysis reactors and the logistics of sourcing feedstock remain significant barriers to widespread adoption.

Making the Right Choice for Your Goal

The "best" biochar is the one engineered for a specific purpose. Your intended application must guide the selection or production process.

- If your primary focus is long-term carbon sequestration: You need a high-temperature (>600°C) biochar made from woody biomass to maximize carbon stability and permanence in the soil.

- If your primary focus is improving soil fertility: You should use a lower-temperature biochar made from a nutrient-rich feedstock like manure or crop residue to act as a slow-release fertilizer.

- If your primary focus is environmental remediation: You need a high-temperature, high-surface-area biochar designed to adsorb specific pollutants like heavy metals or organic chemicals.

Ultimately, biochar is a highly versatile material whose function is deliberately designed through the careful control of the pyrolysis reaction.

Summary Table:

| Key Factor | Impact on Biochar |

|---|---|

| Temperature | Low temp (350–500°C): higher yield, more nutrients. High temp (600–800°C): more stable, porous, ideal for carbon sequestration. |

| Feedstock | Woody biomass: high carbon, low ash. Manures: nutrient-rich, acts as slow-release fertilizer. |

| Heating Rate | Slow pyrolysis: maximizes biochar yield. Fast pyrolysis: maximizes bio-oil production. |

| Primary Use | Carbon sequestration: high-temp, woody biochar. Soil fertility: low-temp, nutrient-rich biochar. |

Ready to engineer the perfect biochar for your specific needs?

KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and production. Whether you're focused on soil enhancement, carbon sequestration, or environmental remediation, our expertise helps you optimize pyrolysis conditions to create biochar with precisely the properties you require.

Contact us today to discuss how our solutions can advance your biochar projects and deliver measurable results.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What type of pyrolysis occurs at rapid heating rates and moderate temperatures? Maximizing Bio-Oil Yield

- What are the advantages of rotary kiln? Achieve Superior Uniformity in High-Temperature Processing

- What are the components of a rotary furnace? A Guide to Its Core Systems for Uniform Heating

- What energy product is produced by pyrolysis? Biochar, Bio-oil, and Syngas Explained

- Why choose pyrolysis? Turn Waste into Valuable Resources with Advanced Thermal Conversion

- Does pyrolysis of plastic produce co2? Unpacking the Emissions of a Circular Technology

- What are the feedstocks used in pyrolysis? Unlock the Potential of Diverse Organic Materials

- What happens to the feedstock during pyrolysis? A Guide to Controlled Thermal Decomposition