The essential first step before any Physical Vapor Deposition (PVD) coating is a rigorous, multi-stage cleaning process. This typically involves mechanical or abrasive methods like blasting or polishing to create the desired surface texture, followed by an aqueous ultrasonic cleaning phase with specialized detergents to remove all oils, greases, and organic films. The part is then thoroughly rinsed and dried to ensure a perfectly pristine surface ready for coating.

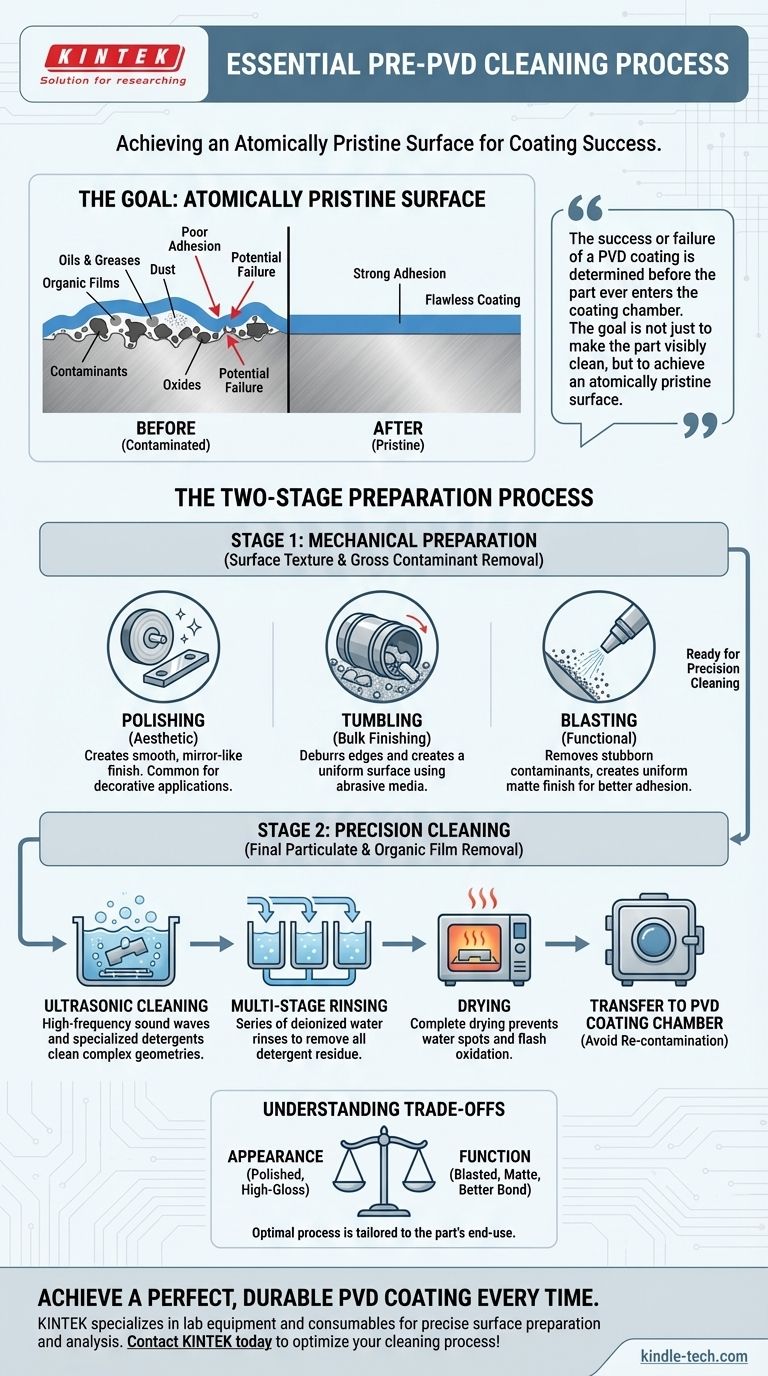

The success or failure of a PVD coating is determined before the part ever enters the coating chamber. The goal is not just to make the part visibly clean, but to achieve an atomically pristine surface, as even microscopic contaminants will prevent proper coating adhesion and create defects.

The Goal: An Atomically Pristine Surface

PVD is a line-of-sight process where a material is deposited one atom at a time in a vacuum. The quality of this atomic-level bond is entirely dependent on the condition of the substrate surface.

Why Perfect Cleanliness is Non-Negotiable

Any foreign material—oils from handling, residual lubricants, oxides, or even dust—acts as a barrier. This prevents the coating material from forming a direct, strong bond with the substrate.

The result is poor adhesion, which can lead to the coating flaking, peeling, or blistering under stress. A contaminated surface guarantees a failed coating.

The Core Cleaning & Preparation Stages

The preparation process can be broken down into two main categories: initial surface texturing and final precision cleaning. The specific methods chosen depend on the substrate material, its initial condition, and the desired final appearance.

Stage 1: Mechanical Surface Preparation

This stage addresses the physical texture of the part and removes gross contaminants like scale, heavy oxides, or recast layers from processes like EDM.

- Polishing: Used to create a smooth, bright, mirror-like finish. This is common for decorative applications where aesthetics are paramount.

- Tumbling: A bulk finishing process where parts are processed in a tumbler with abrasive media to deburr edges and create a uniform surface.

- Sand or Glass-Bead Blasting: Involves projecting abrasive media at the surface. This technique is excellent for removing stubborn contaminants and creating a uniform, non-directional matte finish that can improve coating adhesion for functional parts.

Stage 2: Aqueous & Ultrasonic Cleaning

After mechanical preparation, the part must undergo precision cleaning to remove all fine particulate and organic films.

- Ultrasonic Cleaning: This is the cornerstone of PVD preparation. Parts are submerged in a tank with specialized, environmentally friendly detergents. High-frequency sound waves create microscopic cavitation bubbles that implode on the part's surface, scrubbing it clean even in tiny crevices and complex geometries.

- Multi-Stage Rinsing: After the detergent bath, parts go through a series of rinse tanks, often using deionized water, to remove any remaining detergent residue.

- Drying: The final step is drying the parts completely, typically in a hot air oven, to prevent water spots or flash oxidation before they are moved to the vacuum chamber.

Understanding the Trade-offs

Choosing a cleaning protocol is a balance between the required finish, the part's material, and cost. There is no single process that fits all applications.

Appearance vs. Function

The choice between polishing and blasting is a primary example. A polished surface provides a decorative, high-gloss appearance. A blasted surface provides a functional matte finish that can hide minor surface imperfections and often promotes better mechanical bonding for hard-use coatings.

Abrasive vs. Non-Abrasive

Mechanical methods like blasting are inherently abrasive and can slightly alter the dimensions of a part. For extremely high-tolerance components, this must be accounted for, or a less aggressive cleaning method must be selected.

Chemical Etching

In some cases, acid etching may be used to remove tough oxides from specific materials. While effective, this is a highly controlled process that carries the risk of over-etching or damaging the substrate if not managed perfectly.

Making the Right Choice for Your Goal

The optimal cleaning process is always tailored to the part's end-use. Once cleaned, parts must be handled with gloves and immediately transferred for coating to avoid re-contamination.

- If your primary focus is a decorative, mirror-like finish: Your process must include mechanical polishing followed by a multi-stage ultrasonic wash, rinse, and dry cycle.

- If your primary focus is maximum adhesion on a functional tool: Abrasive blasting to create a uniform matte texture, followed by thorough ultrasonic cleaning, is the standard approach.

- If your primary focus is coating a part with complex internal features: Advanced, multi-stage ultrasonic cleaning is critical to ensure cleaning solutions reach every surface, followed by meticulous rinsing and drying.

Ultimately, treating surface preparation as the most foundational step in the coating process is the key to achieving a flawless and durable PVD finish.

Summary Table:

| Stage | Key Processes | Primary Goal |

|---|---|---|

| 1. Mechanical Preparation | Polishing, Tumbling, Blasting | Remove gross contaminants, create desired surface texture |

| 2. Precision Cleaning | Ultrasonic cleaning with detergents, multi-stage rinsing, drying | Remove all oils, greases, and organic films for an atomically clean surface |

Achieve a perfect, durable PVD coating every time. The right surface preparation is critical for coating success. KINTEK specializes in lab equipment and consumables for precise surface preparation and analysis, serving laboratories that demand reliability. Let our experts help you optimize your cleaning process for flawless results.

Contact KINTEK today to discuss your specific application needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings