In short, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is known for a relatively high deposition rate compared to other low-temperature techniques. However, there is no single deposition rate for PECVD; the rate is a highly variable parameter that depends entirely on the specific process recipe, the material being deposited, and the equipment used.

The crucial insight is that the defining characteristic of PECVD is not just its speed, but its ability to achieve this high rate at low temperatures (around 350°C or less). The deposition rate is a process variable you must optimize, not a fixed constant of the technology.

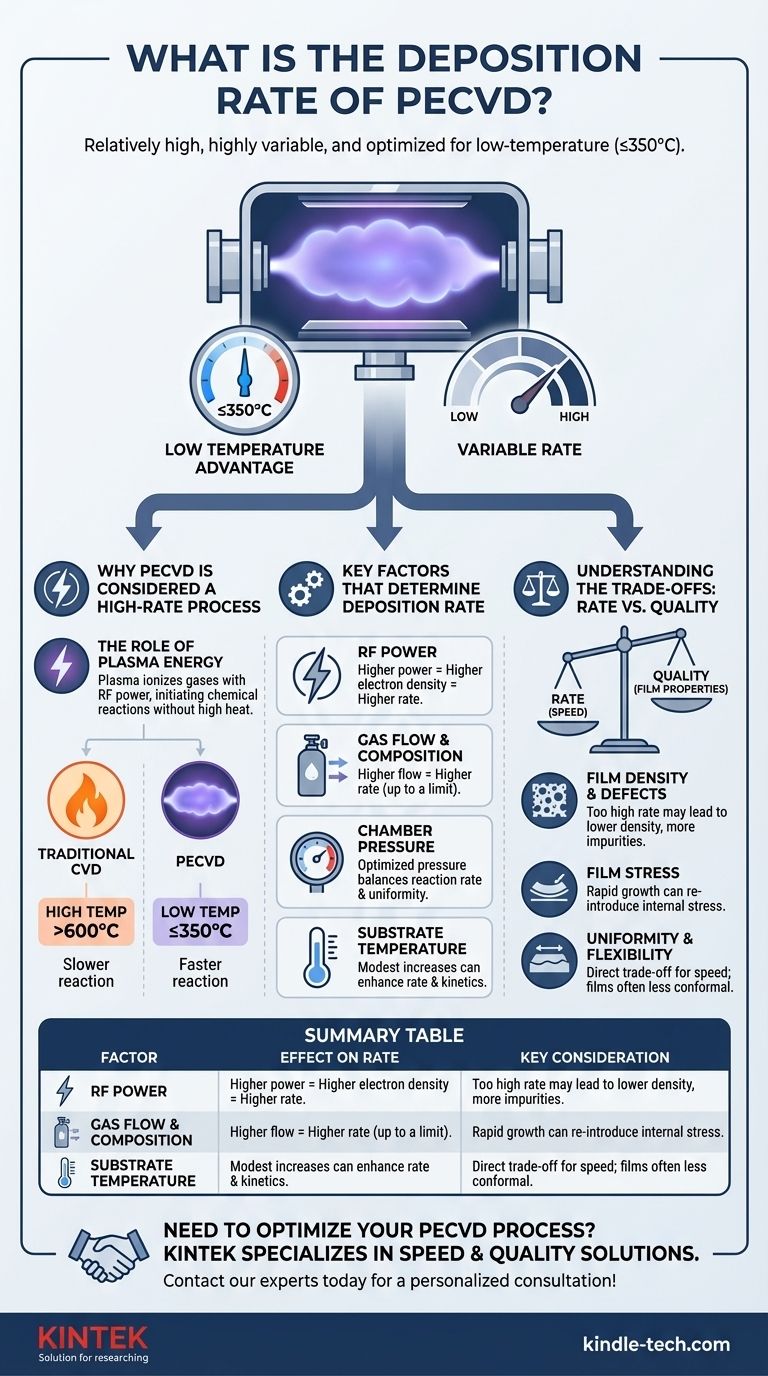

Why PECVD is Considered a High-Rate Process

The speed of PECVD comes from its core mechanism: the use of plasma to drive chemical reactions. This bypasses the need for high thermal energy, which is the limiting factor in many other deposition methods.

The Role of Plasma Energy

In traditional Chemical Vapor Deposition (CVD), high temperatures (often >600°C) are required to provide enough energy to break down the reactant gases and start the deposition reaction on the substrate.

PECVD uses a radio frequency (RF) power supply to ionize the gases, creating a plasma. This plasma contains highly energetic electrons and ions that collide with and decompose the reactant gas molecules, initiating the chemical reaction at a much lower temperature.

The Low-Temperature Advantage

This ability to deposit films at low temperatures is the primary advantage of PECVD. It directly enables a higher deposition rate for applications where high temperature is not an option.

The low-temperature process prevents thermal damage to the substrate, minimizes unwanted reactions between the film and the substrate, and reduces the internal stress that can form when materials with different thermal expansion rates are cooled down.

Key Factors That Determine Deposition Rate

You do not choose PECVD for a fixed rate; you tune the process to achieve a desired rate. The rate is a direct outcome of several interconnected process parameters.

RF Power

The power applied to create the plasma is a primary driver. Increasing RF power generally increases the density of energetic electrons, leading to more efficient gas decomposition and a higher deposition rate.

Gas Flow and Composition

The rate at which reactant gases are supplied to the chamber is critical. A higher flow rate can increase deposition speed, but only up to a point where the reaction becomes limited by other factors, like RF power or pressure.

Chamber Pressure

Pressure inside the reaction chamber affects the plasma's density and the mean free path of gas molecules. Optimizing pressure is essential for balancing the rate of reaction with the uniformity of the film being deposited.

Substrate Temperature

Even though PECVD is a "low-temperature" process, temperature still plays a role. A modest increase in substrate temperature can enhance surface mobility and reaction kinetics, which can sometimes increase the deposition rate and improve film quality.

Understanding the Trade-offs: Rate vs. Quality

Aggressively optimizing for the highest possible deposition rate almost always involves a compromise in the quality of the resulting film.

Impact on Film Density and Defects

Pushing the deposition rate too high can result in films that are less dense, more porous, or contain a higher concentration of impurities like hydrogen. The molecules simply don't have enough time to settle into an ideal, low-energy state on the surface.

Impact on Film Stress

While PECVD is known for producing low-stress films, extremely high deposition rates can re-introduce stress. This happens because the rapid film growth can "lock in" structural disorder.

Uniformity and Flexibility

According to process characteristics, PECVD films are often less flexible and conformal (able to coat complex shapes evenly) than films from slower, high-temperature processes like LPCVD (Low-Pressure CVD). This is a direct trade-off for speed and low temperature.

Making the Right Choice for Your Goal

The "correct" deposition rate is the one that meets the requirements of your specific application. You must balance throughput against film quality.

- If your primary focus is maximum throughput: Optimize RF power and gas flow for the highest rate, but be prepared to test and verify that the resulting film quality (e.g., density, stress, electrical properties) is still within your acceptable limits.

- If your primary focus is high-quality film properties: Start with a moderate, stable deposition rate. Focus on precise control of temperature and pressure to create a dense, uniform, and low-stress film.

- If your primary focus is depositing on sensitive substrates: Leverage the core strength of PECVD—its low temperature. The deposition rate is a secondary parameter you can adjust to achieve your goal without damaging the underlying material.

Ultimately, the deposition rate in PECVD is a powerful, adjustable parameter that you must engineer to balance speed with the specific film characteristics your project demands.

Summary Table:

| Factor | Effect on Deposition Rate | Key Consideration |

|---|---|---|

| RF Power | Higher power increases rate | Must balance with film quality and uniformity |

| Gas Flow/Composition | Higher flow can increase rate up to a limit | Critical for controlling film stoichiometry |

| Chamber Pressure | Affects plasma density and reaction kinetics | Optimization is key for rate and uniformity balance |

| Substrate Temperature | Modest increases can enhance rate | Core advantage is low-temperature operation (≤350°C) |

Need to Optimize Your PECVD Process for Speed and Quality?

KINTEK specializes in lab equipment and consumables, providing the expertise and solutions to help you master your PECVD deposition parameters. Whether your goal is maximum throughput, superior film quality, or processing sensitive substrates, we can help you achieve the perfect balance.

Let's discuss your specific application and how we can enhance your laboratory's capabilities. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application