At a fundamental level, the difference between a standard grinder and a wet grinder lies in their mechanism and purpose. A standard "mixer grinder" uses high-speed rotating blades to chop and pulverize ingredients, generating significant heat. A wet grinder, in contrast, uses heavy, slow-moving grinding stones to crush and shear ingredients with minimal heat, mimicking a traditional stone grinding process.

The core distinction is not about one being better, but about choosing the right tool for the job. A grinder uses speed for quick, dry tasks, while a wet grinder uses pressure and time for superior texture in wet preparations, particularly batters.

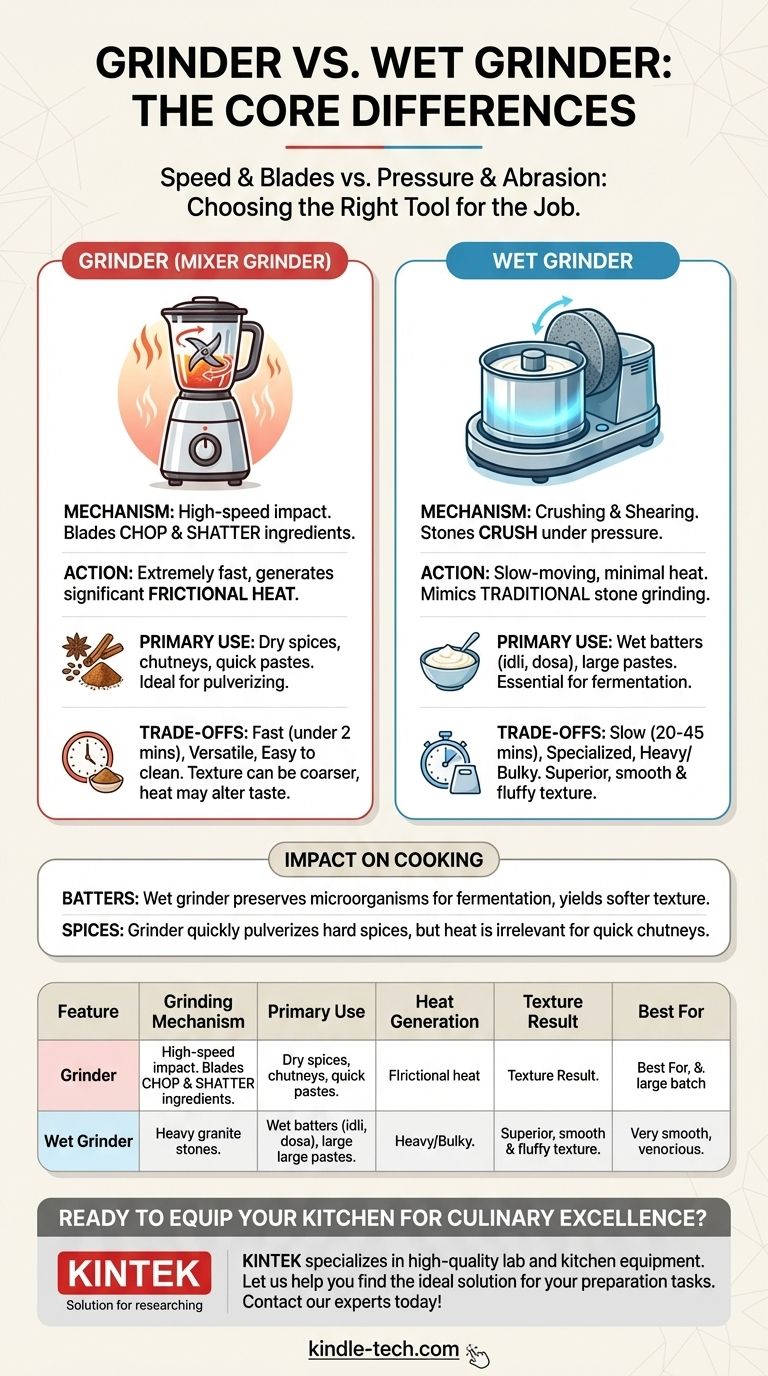

The Core Difference: Mechanism and Principle

To truly understand which appliance to use, you must first grasp how each one works. Their opposing approaches to grinding—speed versus pressure—dictate their ideal applications in the kitchen.

The Grinder (Mixer Grinder): Speed and Blades

A standard mixer grinder operates on the principle of high-speed impact. Its powerful motor spins small, sharp blades at a very high RPM (Revolutions Per Minute).

These blades don't truly "grind"; they violently chop and shatter ingredients into progressively smaller pieces. This process is extremely fast but generates considerable frictional heat.

Think of it as a highly specialized and powerful blender, designed for pulverizing both dry and wet ingredients into powders or coarse pastes.

The Wet Grinder: Pressure and Abrasion

A wet grinder works on a principle of crushing and shearing. It uses a low-speed motor to rotate one or more heavy granite stones against a stationary stone base.

Ingredients are caught between the stones and are crushed under pressure. This action breaks down the cellular structure of grains and lentils without generating significant heat.

This mechanism is an automated version of a traditional mortar and pestle, prioritizing texture and preservation of the ingredient's natural flavor over speed.

How This Impacts Your Cooking

The difference in heat generation and grinding texture has a profound impact on the final dish, especially in delicate preparations like fermented batters.

Why Wet Grinders Excel at Batters

Wet grinders are the specialized tool for making batters for dishes like idli, dosa, and vada. The slow, heat-free process is critical for two reasons.

First, the lack of heat preserves the microorganisms on the surface of the lentils and rice, which are essential for proper fermentation. Excessive heat from a mixer grinder can kill these organisms, leading to a flat, dense batter.

Second, the crushing action creates a uniquely smooth and fluffy texture that high-speed blades cannot replicate. This results in softer idlis and crispier dosas.

Why Standard Grinders Excel at Dry Spices and Chutneys

For tasks like creating spice blends (masalas) from whole spices, the speed of a mixer grinder is a major advantage. It can quickly pulverize hard spices like cinnamon and cloves into a fine powder.

It is also the ideal tool for making quick chutneys and pastes. While it generates some heat, it is usually not detrimental to these preparations, and the task is completed in a minute or two.

Understanding the Practical Trade-offs

Choosing between these appliances involves balancing quality, time, and convenience.

Texture and Taste

A wet grinder produces a superior, more authentic texture for batters and large-quantity pastes. The taste is cleaner because the ingredients are never "cooked" by the friction of the blades.

A mixer grinder can slightly alter the taste of sensitive ingredients due to heat. The final texture, while often fine, can be coarser than what a wet grinder achieves.

Time and Quantity

A mixer grinder is extremely fast. Most tasks are completed in under two minutes. It is also more efficient for grinding very small quantities.

A wet grinder is a slow, deliberate process. Grinding a batch of batter typically takes between 20 and 45 minutes. It is designed to handle larger quantities efficiently.

Versatility

A modern mixer grinder is a multi-purpose workhorse. It typically comes with several jars for dry grinding, wet chutney making, and liquid blending, making it highly versatile for daily kitchen tasks.

A wet grinder is a specialist tool. Its primary function is grinding batters. While some models have attachments for kneading dough or scraping coconuts, its core application is narrow.

Cleaning and Space

Mixer grinder jars are relatively small and easy to wash. The entire unit has a smaller footprint on the counter.

Wet grinders are heavy and bulky due to the solid granite stones. Disassembling and cleaning the stones requires more effort.

Which Appliance is Right for You?

Your choice depends entirely on your culinary goals and the types of dishes you prepare most often.

- If your primary focus is making authentic Indian batters for idli and dosa: A wet grinder is non-negotiable for achieving the correct texture and fermentation.

- If your primary focus is grinding dry spices, making daily chutneys, and general blending: A high-quality mixer grinder is the more versatile and practical choice.

- If you are a serious home cook exploring a wide range of cuisines: You will likely find a need for both, using the mixer grinder for quick, daily tasks and the wet grinder for specialized preparations.

Understanding the fundamental difference between high-speed chopping and low-speed crushing empowers you to select the precise tool for the perfect culinary result.

Summary Table:

| Feature | Grinder (Mixer Grinder) | Wet Grinder |

|---|---|---|

| Grinding Mechanism | High-speed rotating blades | Slow-moving granite stones |

| Primary Use | Dry spices, chutneys, quick pastes | Wet batters (idli, dosa), large pastes |

| Heat Generation | High (due to friction) | Minimal (preserves fermentation) |

| Texture Result | Coarser, suitable for powders | Superiorly smooth and fluffy |

| Best For | Versatility, speed, daily tasks | Authentic texture, fermentation-critical dishes |

Ready to Equip Your Kitchen for Culinary Excellence?

Whether you need a versatile grinder for daily spice blending or a specialized wet grinder for authentic batters, having the right equipment is key to achieving perfect results. KINTEK specializes in providing high-quality lab and kitchen equipment to meet your precise needs.

Let us help you find the ideal solution for your preparation tasks.

Contact our experts today to discuss your requirements and discover how our reliable equipment can enhance your efficiency and outcomes!

Visual Guide

Related Products

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

- Powerful Plastic Crusher Machine

- Lab Vibration Mill

People Also Ask

- What food is cryogenic grinding? The Ultimate Guide to Preserving Flavor & Aroma

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- What is the function of mechanical grinding equipment in lignocellulosic pretreatment? Maximize Yeast Biodiesel Yields

- Why is a cryogenic grinder required for cured alkyd resin HRMAS NMR? Ensure Structural Integrity & Sample Precision

- What is cold grinding? Achieve Ultra-Fine Particles Without Thermal Damage