At its core, the difference is the presence of a liquid. A wet ball mill grinds materials within a liquid medium, typically water or a solvent, to form a slurry. In contrast, a dry ball mill operates without any liquid, grinding the material in its natural, dry state. This fundamental distinction dictates the efficiency, final particle size, and suitability of the process for different materials.

The choice between wet and dry milling is not about which is universally "better," but which is appropriate for your specific goal. Wet milling is the superior method for producing extremely fine particles and preventing material agglomeration, while dry milling offers process simplicity when a dry final product is needed and ultra-fine grinding is not the primary objective.

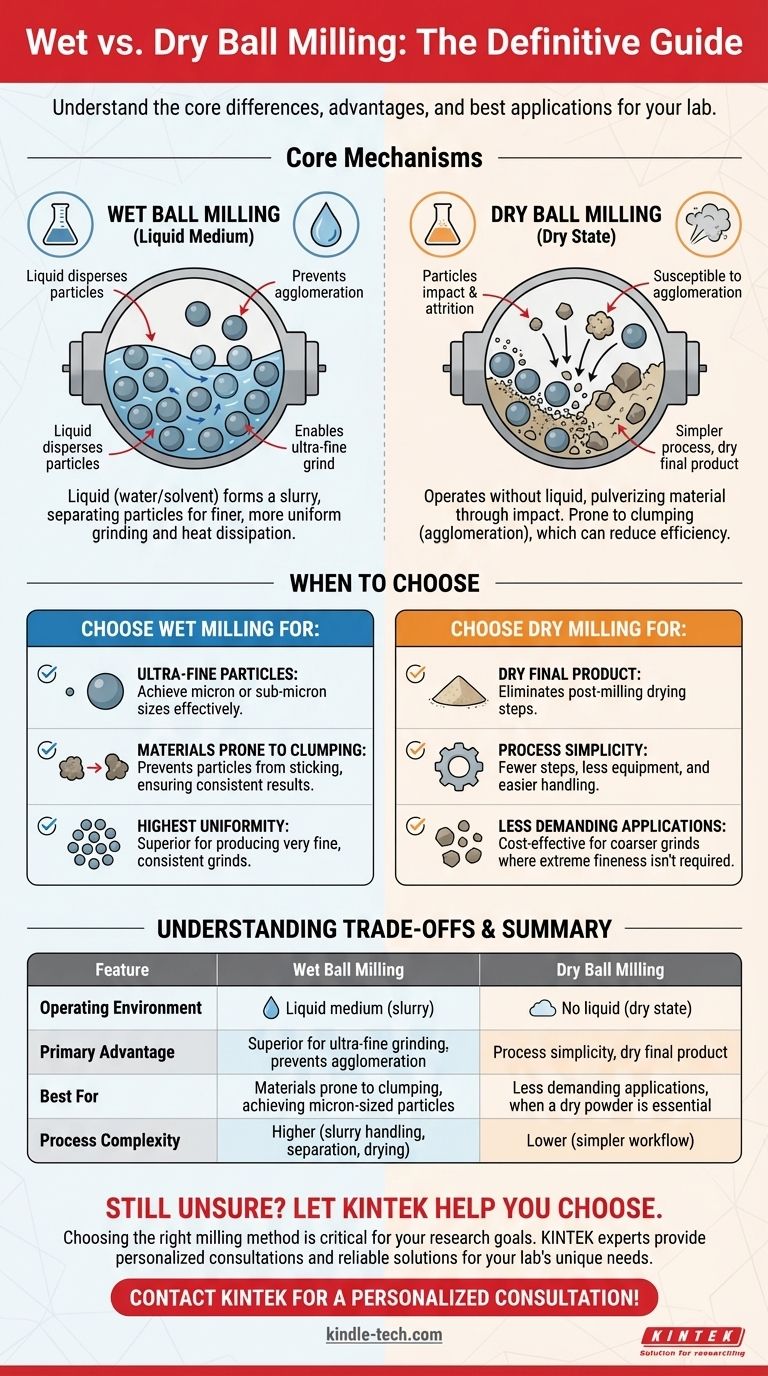

Core Mechanisms: How Each Process Works

The operating environment inside the mill fundamentally changes the grinding dynamics and the nature of the final product. Understanding this is key to selecting the right method.

The Role of Liquid in Wet Milling

In wet milling, the material is mixed with a liquid to create a slurry. This liquid isn't just a passive filler; it plays several critical roles.

The liquid medium helps to disperse the particles, preventing fine powders from clumping back together (agglomeration) due to electrostatic forces.

This constant separation allows the grinding media (the balls) to make efficient contact with individual particles, enabling a much finer and more uniform final grind. It also helps dissipate heat generated during milling and reduces wear on the mill components.

The Simplicity of Dry Milling

Dry milling is a more straightforward process. The material is simply loaded into the mill with the grinding media and pulverized through impact and attrition.

Without a liquid dispersant, this method is more susceptible to agglomeration, where fine particles stick together. This can create a cushioning effect that reduces grinding efficiency, especially when targeting very small particle sizes.

The primary advantage is simplicity, as it avoids the need for handling slurries and eliminates a post-milling drying step.

When to Choose Wet vs. Dry Milling

Your material's properties and your desired outcome are the deciding factors. Each method excels under different conditions.

Use Wet Milling for Ultra-Fine Particles

If your goal is to reduce a material to the smallest possible particle size (into the micron or sub-micron range), wet milling is almost always the more efficient choice.

The liquid prevents the newly fractured, fine particles from re-bonding, allowing the milling process to continue breaking them down effectively.

Use Wet Milling for Materials Prone to Clumping

For materials with a high tendency to agglomerate or stick together, wet milling is superior. The slurry environment physically separates the particles, ensuring consistent and efficient grinding.

Use Dry Milling When a Dry Product is Essential

If your downstream process requires a dry powder, dry milling eliminates the costly and time-consuming step of drying a slurry. This simplifies the overall workflow significantly.

Use Dry Milling for Less Demanding Applications

When extreme fineness is not a requirement and the material has a low tendency to clump, dry milling is often the more practical and cost-effective method.

Understanding the Trade-offs

Choosing a method involves balancing efficiency, complexity, and cost. There is no single solution that fits all scenarios.

Efficiency and Particle Size

For achieving a very fine grind, wet milling is more energy-efficient. It overcomes the physical barriers of agglomeration that can stall the size-reduction progress in a dry environment.

However, for a coarser grind, dry milling can be more efficient because it eliminates the energy and time required for subsequent drying.

Process Complexity and Cost

Dry milling is fundamentally a simpler process. It involves fewer steps, less equipment (no pumps, filters, or dryers), and easier material handling.

Wet milling introduces complexity through slurry preparation, containment, and post-process separation and drying. This translates to higher initial capital costs and potentially higher operating costs.

Material Compatibility

The choice can be dictated by the material itself. Some materials may react chemically with the liquid medium (especially water), making dry milling the only viable option.

Making the Right Choice for Your Goal

To make a definitive decision, evaluate your primary objective.

- If your primary focus is achieving the finest possible particle size: Wet ball milling is the more effective and efficient method.

- If your primary focus is process simplicity and a dry final product: Dry ball milling is the clear choice, provided the material doesn't severely agglomerate.

- If your primary focus is grinding a material that is sticky or easily clumps: Wet ball milling will provide a much more consistent and successful result.

Ultimately, the right milling technique is the one that aligns directly with your material's properties and the specific requirements of your final product.

Summary Table:

| Feature | Wet Ball Milling | Dry Ball Milling |

|---|---|---|

| Operating Environment | Liquid medium (slurry) | No liquid (dry state) |

| Primary Advantage | Superior for ultra-fine grinding, prevents agglomeration | Process simplicity, dry final product |

| Best For | Materials prone to clumping, achieving micron-sized particles | Less demanding applications, when a dry powder is essential |

| Process Complexity | Higher (slurry handling, separation, drying) | Lower (simpler workflow) |

Still Unsure Which Milling Method is Best for Your Lab?

Choosing between wet and dry ball milling is critical for achieving your desired particle size and maintaining process efficiency. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and reliable solutions.

Let our experts help you select the perfect ball mill for your specific material and application. We can guide you to the most efficient and cost-effective solution for your grinding challenges.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What are the parameters of a planetary ball mill? Master Speed, Time, and Media for Perfect Grinding

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- What are the advantages of planetary ball milling? Achieve High-Energy Grinding and Material Synthesis

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation