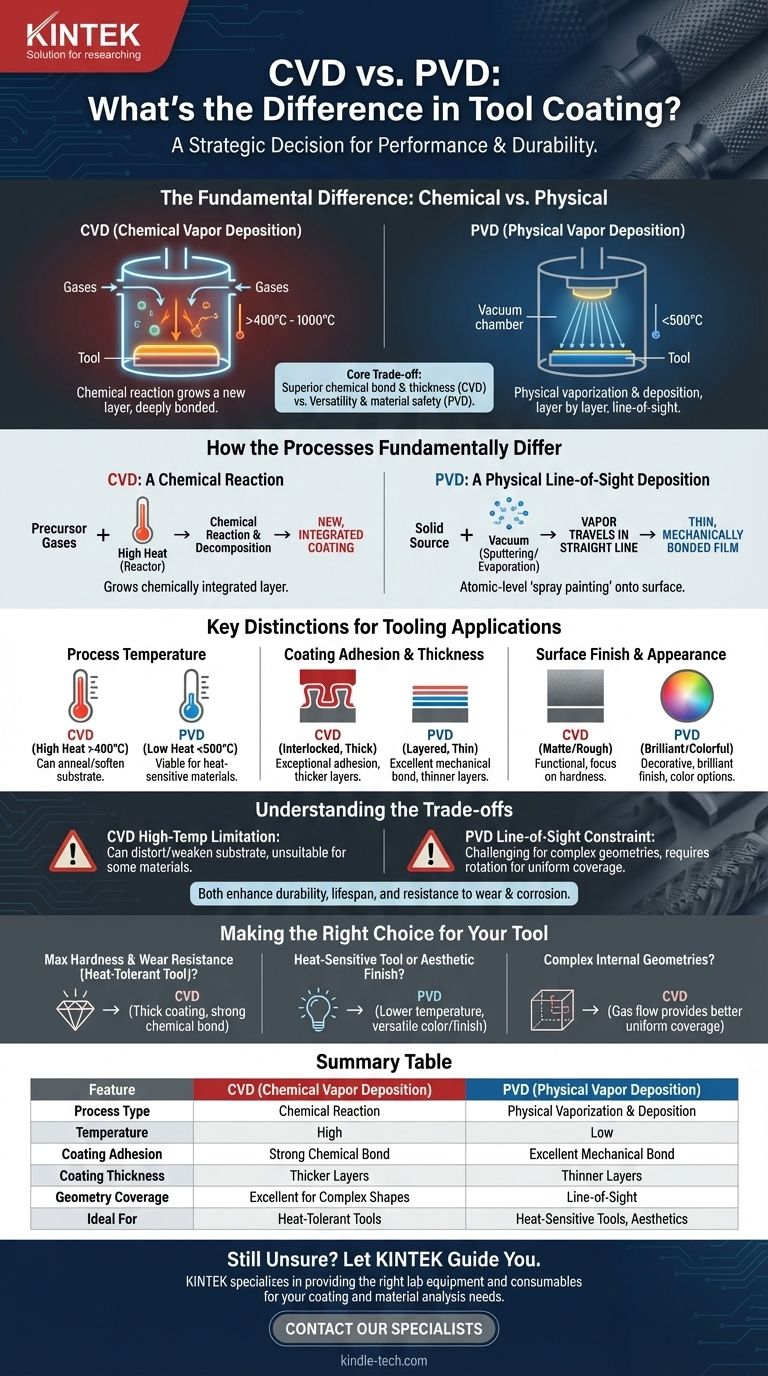

The fundamental difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how the coating material is applied to the tool's surface. CVD uses a chemical reaction where precursor gases form a new coating directly on the substrate at high temperatures. In contrast, PVD is a physical process that vaporizes a solid material in a vacuum and deposits it, layer by layer, onto the tool at much lower temperatures.

The choice between CVD and PVD is a strategic decision balancing the superior chemical bond and thickness of high-temperature CVD against the versatility and material safety of lower-temperature PVD. The right choice is determined entirely by the tool's base material and its intended application.

How the Processes Fundamentally Differ

To select the right coating, you must first understand the core mechanism of each method. They are not interchangeable processes; they are fundamentally different in their approach to building a surface layer.

CVD: A Chemical Reaction on the Surface

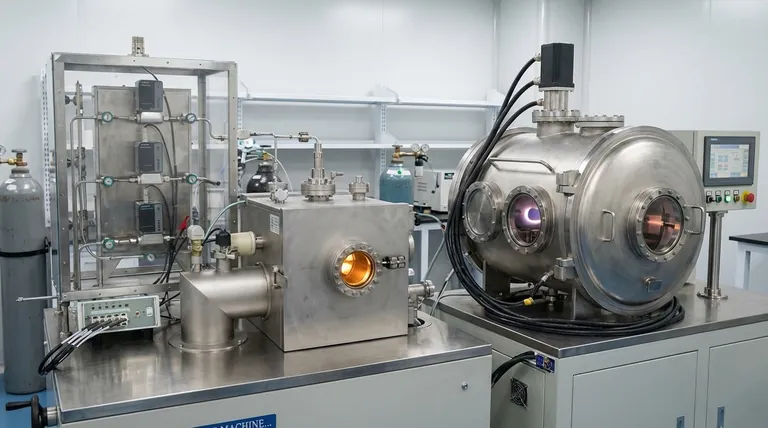

In Chemical Vapor Deposition, the tool is placed in a reactor chamber and heated to a high temperature. Volatile precursor gases are then introduced.

These gases react with each other and with the tool's surface, decomposing to form an entirely new, dense, and strongly bonded coating material. It's less like painting a surface and more like growing a new layer that is chemically integrated with the substrate.

PVD: A Physical Line-of-Sight Deposition

In Physical Vapor Deposition, the process occurs in a vacuum chamber. A solid source material (like titanium or chromium) is vaporized through methods like sputtering or evaporation.

This vapor travels in a straight line and condenses onto the cooler tool surface, forming a thin, bonded film. This is a mechanical or physical process, much like an atomic-level spray painting, without a chemical transformation of the coating material itself.

Key Distinctions for Tooling Applications

The differences in process lead to critical distinctions in performance, appearance, and which tools can be safely coated.

Process Temperature

This is often the single most important deciding factor. CVD is a high-temperature process, typically operating between 400°C and 1000°C.

PVD, on the other hand, is a much cooler process. This lower temperature makes it the only viable option for coating substrates that are sensitive to heat, such as certain tool steels or materials whose hardness (temper) would be ruined by CVD's high heat.

Coating Adhesion and Thickness

Because CVD involves a chemical reaction, the resulting coating is deeply interlocked with the substrate, providing exceptional adhesion. CVD coatings can also be applied in thicker layers.

PVD coatings have excellent adhesion but are mechanically bonded to the surface rather than chemically grown from it. These coatings are typically much thinner than CVD coatings.

Surface Finish and Appearance

PVD is renowned for producing a brilliant, decorative finish and can be applied in a wide range of colors. This makes it ideal for applications where appearance is a factor.

CVD coatings are primarily functional, focused on hardness and wear resistance, and typically do not offer the same level of aesthetic control.

Understanding the Trade-offs

Neither method is universally superior. Your choice involves accepting a specific set of advantages and limitations.

The High-Temperature Limitation of CVD

The primary drawback of CVD is its heat. While this heat creates a very strong bond, it can also anneal, soften, or distort the underlying tool material. It is completely unsuitable for materials that cannot withstand these temperatures without losing their essential structural properties.

The Line-of-Sight Constraint of PVD

Because PVD deposits material in a straight line from the source, it can be challenging to achieve a uniform coating on tools with complex shapes or deep internal channels. The parts often need to be rotated to ensure even coverage. CVD gases, by contrast, can flow around and into complex geometries, providing a more uniform coating.

Durability and Resistance

Both processes significantly enhance a tool's durability, lifespan, and resistance to wear and corrosion. CVD often provides a harder, more wear-resistant surface due to its thickness and chemical bond, making it a classic choice for demanding cutting tools made from materials like cemented carbide. PVD offers excellent improvements in lubricity and wear resistance on a wider variety of tool materials.

Making the Right Choice for Your Tool

Your specific application and tool material dictate the optimal choice. The decision should not be based on which process is "better" in a vacuum, but which is appropriate for the job.

- If your primary focus is maximum hardness and wear resistance on a heat-tolerant tool (like carbide inserts): CVD is often the superior choice due to its thicker coating and incredibly strong chemical bond.

- If your primary focus is coating a heat-sensitive tool steel or you need an aesthetic finish: PVD is the only viable option due to its lower process temperature and versatility in color and finish.

- If your primary focus is coating a tool with complex internal geometries: CVD's gas-based nature generally provides more uniform coverage in hard-to-reach areas compared to the line-of-sight PVD process.

Understanding these core principles moves the decision from a guess to a calculated engineering choice.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Process Type | Chemical Reaction | Physical Vaporization & Deposition |

| Temperature | High (400°C - 1000°C) | Low (Typically < 500°C) |

| Coating Adhesion | Strong Chemical Bond | Excellent Mechanical Bond |

| Coating Thickness | Thicker Layers | Thinner Layers |

| Geometry Coverage | Excellent for Complex Shapes | Line-of-Sight (May Require Rotation) |

| Ideal For | Heat-Tolerant Tools (e.g., Carbide) | Heat-Sensitive Tools, Aesthetic Finishes |

Still Unsure Which Coating Process is Best for Your Specific Tools?

The choice between CVD and PVD is critical for maximizing your tool's performance and lifespan. At KINTEK, we specialize in providing the right lab equipment and consumables for your coating and material analysis needs. Our experts can help you navigate these technical decisions to ensure optimal results for your laboratory or production environment.

Contact our specialists today to discuss your tool coating requirements and discover how KINTEK's solutions can enhance your operations.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films