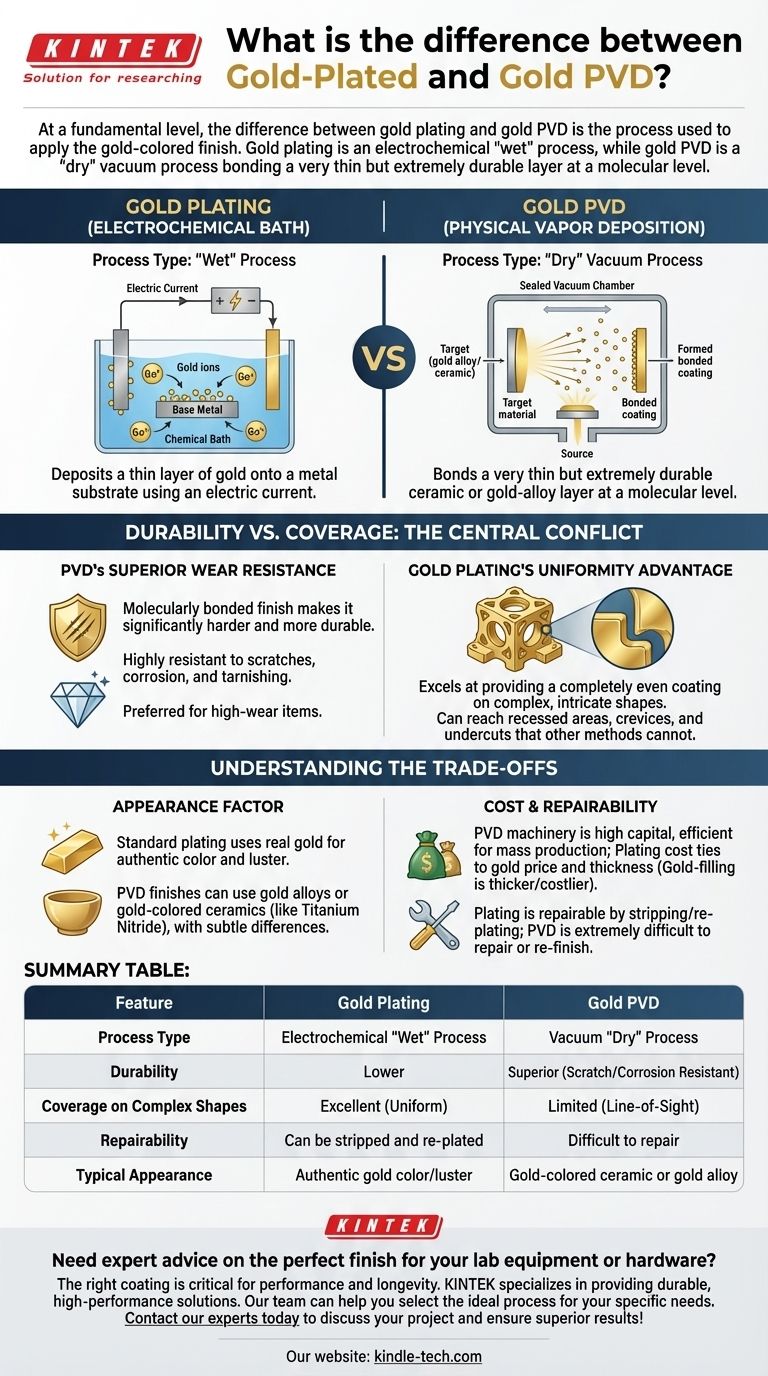

At a fundamental level, the difference between gold plating and gold PVD is the process used to apply the gold-colored finish. Gold plating is an electrochemical "wet" process that uses an electric current to deposit a thin layer of gold onto a metal substrate. In contrast, gold PVD (Physical Vapor Deposition) is a "dry" vacuum process that bonds a very thin but extremely durable ceramic or gold-alloy layer to the surface at a molecular level.

The core decision between gold PVD and gold plating is a trade-off between durability and application complexity. PVD provides superior scratch and wear resistance, while gold plating offers more uniform coverage on intricate shapes.

How the Processes Fundamentally Differ

To choose the right finish, you must first understand how each is created. The method directly dictates the final properties of the product.

Gold Plating: An Electrochemical Bath

Gold plating, or electroplating, is a well-established process. A base metal object is submerged in a chemical solution containing dissolved gold ions.

When an electric current is passed through this bath, the gold ions are deposited onto the surface of the object, creating a thin, solid layer of gold.

Gold PVD: A Vacuum Chamber Transformation

Physical Vapor Deposition is a more modern, high-tech process. The object is placed inside a high-vacuum chamber.

A target of the coating material—either a real gold alloy or, more commonly, a hard ceramic like Titanium Nitride—is vaporized. This vapor then travels through the vacuum and condenses onto the object, forming a very thin, hard, and tightly bonded coating.

Durability vs. Coverage: The Central Conflict

The primary technical differences between these two methods lead to a clear divergence in performance, centered on how they wear and how they are applied.

PVD's Superior Wear Resistance

The PVD process creates a finish that is molecularly bonded to the substrate, making it significantly harder and more durable than electroplated gold.

This makes PVD finishes highly resistant to scratches, corrosion, and tarnishing from sweat or chemicals. It is the preferred choice for items that experience high wear.

Gold Plating's Uniformity Advantage

Electroplating excels at providing a completely even coating, even on highly complex or intricate objects.

Because the object is fully immersed in a liquid solution, the electric field can deposit gold into recessed areas, crevices, and undercuts that other methods can't reach.

The "Line-of-Sight" Limitation of PVD

PVD is a "line-of-sight" process. Think of it like spray painting: the vaporized material can only coat surfaces it can directly "see."

While objects are often rotated during the process to ensure better coverage, PVD can struggle to uniformly coat deep recesses or complex internal geometries.

Understanding the Trade-offs

Neither process is universally superior. The optimal choice depends on balancing cost, appearance, and the intended use of the final product.

The Appearance Factor

Standard gold plating uses real gold, giving it the authentic color and luster one expects.

PVD coatings can be made with real gold alloys, but many common PVD finishes use gold-colored ceramics like Titanium Nitride. While very close in appearance, the color may have a subtle difference from pure gold.

The Cost Implication

The cost is complex. PVD machinery is a significant capital investment, but the process can be very efficient for mass production.

Gold plating costs are more directly tied to the fluctuating price of gold and the desired thickness of the coating. For a thicker gold layer, a process called gold-filling is used, which is significantly more expensive than both plating and PVD.

The Repair and Re-Finishing Challenge

An often-overlooked factor is repairability. A worn gold-plated item can be relatively easily stripped and re-plated to look new again.

A PVD coating is extremely difficult to remove. If a PVD finish is deeply scratched or damaged, it is often considered permanent and cannot be practically repaired or refinished.

Making the Right Choice for Your Goal

To make a definitive decision, evaluate your project's single most important priority.

- If your primary focus is maximum durability and longevity: PVD is the clear choice for items like watches, tools, or high-contact hardware that must resist scratches and wear.

- If your primary focus is coating a complex, intricate shape: Gold plating provides superior and more uniform coverage for detailed jewelry or ornate fixtures with many crevices.

- If your primary focus is the most authentic gold color at a lower cost: Traditional gold plating delivers the look of real gold and is often more affordable than high-end PVD processes that use gold alloys.

- If your primary focus is the thickest possible gold layer: You should investigate gold-filled products, which use heat and pressure to bond a much thicker layer of gold for the highest precious metal content.

By understanding the fundamental trade-off between process and performance, you can select the finish that aligns perfectly with your design's functional and aesthetic goals.

Summary Table:

| Feature | Gold Plating | Gold PVD |

|---|---|---|

| Process Type | Electrochemical "Wet" Process | Vacuum "Dry" Process |

| Durability | Lower | Superior (Scratch/Corrosion Resistant) |

| Coverage on Complex Shapes | Excellent (Uniform) | Limited (Line-of-Sight) |

| Repairability | Can be stripped and re-plated | Difficult to repair |

| Typical Appearance | Authentic gold color/luster | Gold-colored ceramic or gold alloy |

Need expert advice on the perfect finish for your lab equipment or hardware? The right coating is critical for performance and longevity. KINTEK specializes in providing durable, high-performance solutions for laboratory and industrial applications. Our team can help you select the ideal process for your specific needs. Contact our experts today to discuss your project and ensure superior results!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Gold Disc Electrode

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer