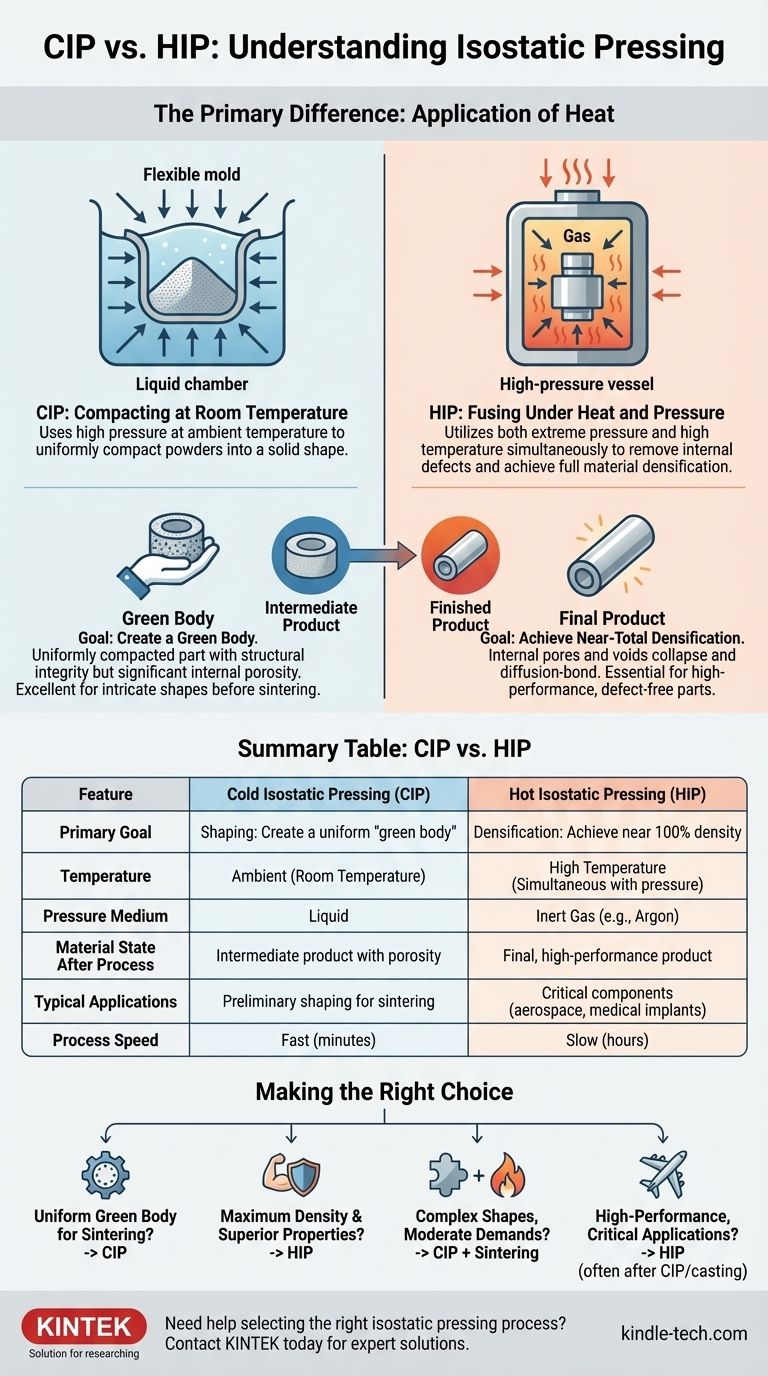

At its core, the primary difference between Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) is the application of heat. CIP uses high pressure at ambient temperature to uniformly compact powders into a solid shape. In contrast, HIP utilizes both extreme pressure and high temperature simultaneously to remove internal defects and achieve full material densification.

Choosing between CIP and HIP is not about selecting a superior process, but about matching the right tool to the task. CIP is fundamentally a shaping process for creating initial forms, while HIP is a thermal treatment for achieving near-total densification and superior material properties.

The Fundamental Processes: Shaping vs. Densification

To understand when to use each process, you must see them as distinct tools for different stages of manufacturing. One is for initial forming, the other for final perfecting.

Cold Isostatic Pressing (CIP): Compacting at Room Temperature

CIP involves placing material powder in a flexible mold and submerging it in a liquid chamber. This liquid is then pressurized, exerting uniform pressure from all directions onto the mold.

The primary goal of CIP is to create a "green body." This is a uniformly compacted part with enough structural integrity to be handled but still containing significant internal porosity.

Because it compacts the powder evenly, CIP is an excellent preliminary step for producing intricate or complex shapes that will undergo further processing, such as sintering or HIP.

Hot Isostatic Pressing (HIP): Fusing Under Heat and Pressure

HIP places a component inside a high-pressure vessel that is then filled with an inert gas, typically Argon. The vessel is heated to very high temperatures while the gas is pressurized.

The combination of heat and isostatic pressure causes the material to become plastic. This allows internal pores and voids within the material to collapse and diffusion-bond together.

The purpose of HIP is not to create the initial shape, but to heal internal defects in castings or consolidate powders into a fully dense, high-performance final product.

Comparing the Outcomes: Green Body vs. Final Product

The state of the material after each process reveals their distinct roles. A part leaving a CIP cycle is an intermediate product, while a part leaving a HIP cycle is often a finished one.

Properties Achieved with CIP

CIP produces a component with highly uniform density. This uniformity is critical because it prevents warping and distortion during subsequent high-temperature processes like sintering.

However, the mechanical properties of a CIP'd part are modest. It is solid but has not yet achieved the strength or toughness required for demanding applications.

Properties Achieved with HIP

HIP results in a material that is close to 100% of its theoretical maximum density. This elimination of porosity dramatically enhances its mechanical properties.

Materials that have undergone HIP exhibit superior strength, ductility, fatigue life, and fracture toughness. This makes the process essential for components where failure is not an option.

Understanding the Trade-offs: Time and Complexity

While HIP delivers superior final properties, those benefits come with significant trade-offs in processing time and complexity.

Process Speed and Throughput

CIP is a relatively fast process, with cycle times often measured in minutes. This makes it suitable for higher-volume preliminary shaping.

HIP is significantly slower, requiring hours for a complete cycle. This is due to the time needed to heat the vessel, apply pressure, hold at temperature, and cool down safely.

Suitable Applications and Geometries

CIP is ideal for creating the initial form of simple or intricate shapes that need uniform density before final sintering. It is a cost-effective shaping method.

HIP is used for the final densification of critical components, often with complex geometries, such as aerospace turbine blades, medical implants, and high-stress industrial tooling.

Making the Right Choice for Your Goal

Your choice between CIP and HIP—or the decision to use them in sequence—depends entirely on your material's performance requirements and application.

- If your primary focus is creating a uniform green body for subsequent sintering: CIP is the correct and most cost-effective choice.

- If your primary focus is achieving maximum density and superior mechanical properties in a final component: HIP is the essential process.

- If your primary focus is producing complex shapes without critical performance demands: A sequence of CIP followed by conventional sintering is often sufficient.

- If your primary focus is manufacturing high-performance, defect-free parts for critical applications: You will almost certainly rely on HIP, often processing a part previously formed by CIP, casting, or additive manufacturing.

Ultimately, understanding these processes as complementary tools—one for shaping, the other for perfecting—is the key to advanced materials manufacturing.

Summary Table:

| Feature | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Primary Goal | Shaping: Create a uniform "green body" | Densification: Achieve near 100% density |

| Temperature | Ambient (Room Temperature) | High Temperature (Simultaneous with pressure) |

| Pressure Medium | Liquid | Inert Gas (e.g., Argon) |

| Material State After Process | Intermediate product with porosity | Final, high-performance product |

| Typical Applications | Preliminary shaping for sintering | Critical components (aerospace, medical implants) |

| Process Speed | Fast (minutes) | Slow (hours) |

Need help selecting the right isostatic pressing process for your lab's materials?

At KINTEK, we specialize in lab equipment and consumables, providing expert solutions for all your materials processing needs. Whether you are shaping a new material with CIP or aiming for maximum densification with HIP, our team can help you choose the right tool to achieve superior results and enhance your lab's efficiency.

Contact us today to discuss your specific application and discover how KINTEK can support your advanced materials manufacturing goals.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- What's the difference between cold press and regular press? Choosing Between Quality and Efficiency

- What is isostatic pressing in powder metallurgy? Unlock Superior Part Density and Complexity

- Purpose of CIP in c-LLZO ceramic pellets? Achieve >90% Density & Superior Uniformity with Cold Isostatic Pressing