At its core, the difference between microwave and conventional pyrolysis is the heating mechanism. Conventional pyrolysis heats material slowly from the outside-in using conduction and convection, much like a standard oven. In contrast, microwave pyrolysis uses electromagnetic waves to heat the material rapidly and volumetrically from the inside-out.

The fundamental distinction is not what happens—the thermal decomposition of material in an oxygen-free environment—but how the heat is delivered. This difference in heat delivery profoundly impacts process speed, energy efficiency, and the quality of the final products.

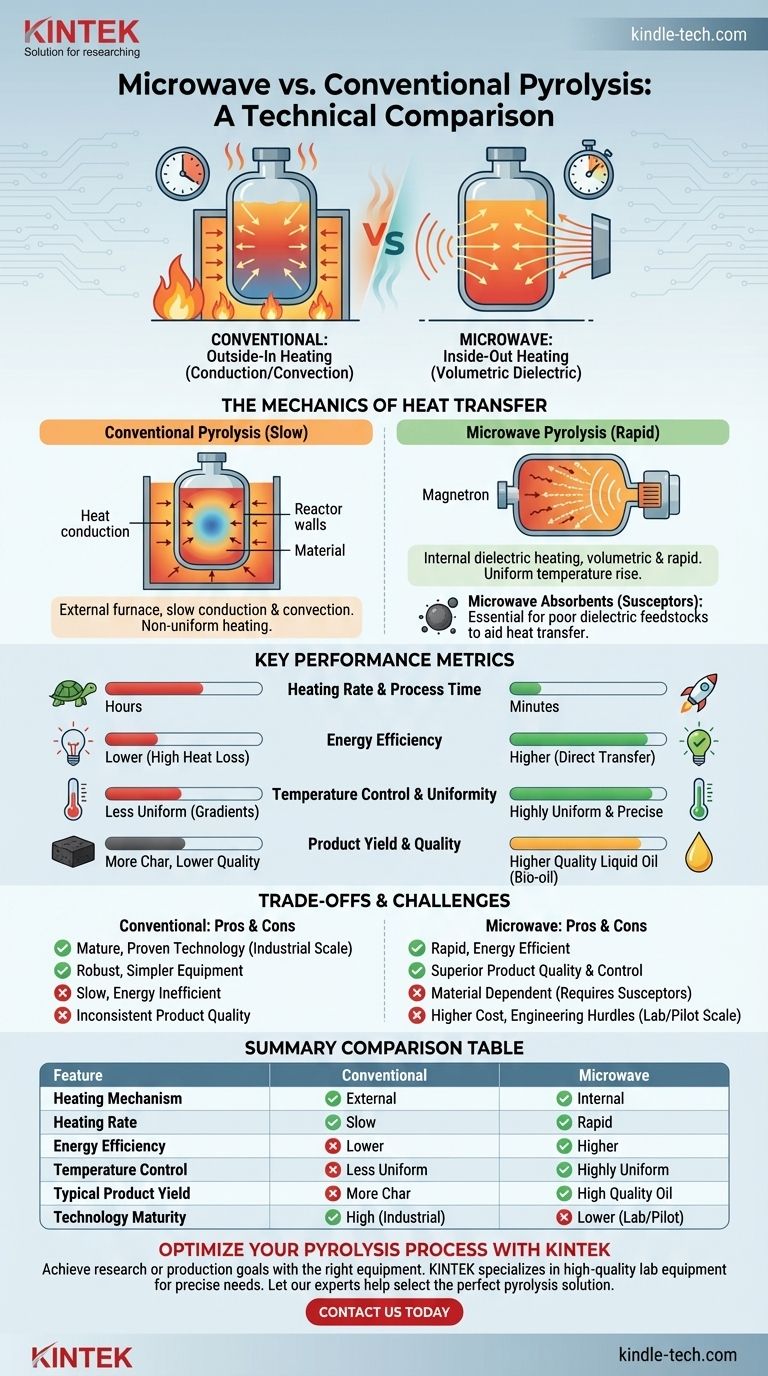

The Mechanics of Heat Transfer: Outside-In vs. Inside-Out

The method of heating is the single most important factor that differentiates these two processes and dictates their respective strengths and weaknesses.

Conventional Pyrolysis: Slow Conduction

In a conventional system, an external furnace heats the walls of a reactor. This thermal energy is then transferred to the feedstock through conduction (direct contact) and convection (fluid movement).

This process is inherently slow and inefficient. A significant temperature gradient forms, meaning the material on the outside of the reactor is much hotter than the material in the center. This leads to non-uniform heating and inconsistent product quality.

Microwave Pyrolysis: Rapid Volumetric Heating

Microwave pyrolysis uses microwave radiation to generate heat directly within the feedstock itself. This is a form of dielectric heating.

Instead of waiting for heat to travel from an external source, the microwaves agitate polar molecules throughout the material simultaneously, causing rapid and uniform temperature rise. This is known as volumetric heating and is analogous to how a microwave oven heats food far more quickly than a conventional oven.

The Critical Role of Microwave Absorbents

A key consideration is that many feedstocks, like certain plastics or dry biomass, have poor dielectric properties and do not absorb microwave energy well.

To overcome this, a microwave-absorbent material, or "susceptor," such as silicon carbide or activated carbon, is often mixed with the feedstock. This absorbent heats up rapidly in the microwave field and then transfers that heat efficiently to the target material through conduction.

Comparing Key Performance Metrics

The difference in heating mechanism creates significant divergences in performance, efficiency, and output.

Heating Rate and Process Time

Microwave pyrolysis offers exceptionally high heating rates, often reaching the target temperature in minutes. Conventional pyrolysis can take hours to heat the same volume of material, resulting in much longer process times and lower throughput.

Energy Efficiency

Microwave pyrolysis is generally more energy-efficient. Energy is delivered directly to the material being processed, with minimal energy wasted heating the large reactor vessel and surrounding insulation. Conventional systems suffer from significant heat loss to the environment.

Temperature Control and Uniformity

Because heat is generated internally, microwave systems provide much more precise and uniform temperature control. This minimizes hot and cold spots, preventing the under-reaction of some material and the over-reaction (or "cracking") of others, which is a common problem in conventional reactors.

Product Yield and Quality

The rapid and uniform heating of microwave pyrolysis often yields superior products. It typically favors the production of high-quality liquid oil (bio-oil) and reduces the formation of less valuable solid char. The resulting oils also tend to have a lower viscosity and are more suitable as chemical feedstocks.

Understanding the Trade-offs and Challenges

While microwave technology offers clear advantages in speed and product quality, it is not without significant challenges that have limited its widespread industrial use.

Material and Scale Limitations

Microwave pyrolysis is highly dependent on the feedstock's dielectric properties, often requiring the addition of susceptors, which adds cost and complexity. Furthermore, designing large-scale microwave reactors is a major engineering hurdle, as ensuring an even microwave field distribution in a large chamber is difficult.

Technology Maturity and Cost

Conventional pyrolysis is a mature, well-understood technology with numerous large-scale industrial installations operating globally. Its equipment is robust and comparatively simpler. Microwave pyrolysis systems are more complex, with higher initial capital costs for components like magnetrons and specialized reactor designs, and are still primarily found at the lab or pilot scale.

Making the Right Choice for Your Goal

The optimal method depends entirely on your specific objectives, from the scale of operation to the desired end product.

- If your primary focus is large-scale, bulk processing of mixed waste with proven technology: Conventional pyrolysis is the more established, reliable, and scalable choice.

- If your primary focus is producing high-quality liquid fuels or specific chemical precursors from a known feedstock: Microwave pyrolysis offers superior control and can yield a more valuable product slate.

- If your primary focus is research, process innovation, and rapid material screening: The speed and precision of microwave pyrolysis make it an ideal platform for development and experimentation.

Ultimately, choosing between these technologies requires a clear understanding of your goal, as each is a different tool designed for a specific type of chemical transformation.

Summary Table:

| Feature | Conventional Pyrolysis | Microwave Pyrolysis |

|---|---|---|

| Heating Mechanism | External, conduction/convection | Internal, volumetric (dielectric) |

| Heating Rate | Slow (hours) | Rapid (minutes) |

| Energy Efficiency | Lower (significant heat loss) | Higher (direct energy transfer) |

| Temperature Control | Less uniform (temperature gradients) | Highly uniform and precise |

| Typical Product Yield | More char | Higher quality liquid oil/bio-oil |

| Technology Maturity | High (industrial scale) | Lower (primarily lab/pilot scale) |

Ready to optimize your pyrolysis process? The right equipment is critical for achieving your research or production goals, whether you prioritize rapid, uniform heating or large-scale, proven technology. KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of laboratories like yours. Let our experts help you select the perfect pyrolysis solution for your specific application. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the raw materials for bio-oil? A Guide to Selecting the Best Biomass Feedstock

- What role does an orbital shaker play in laboratory-scale microbial degradation screening? Optimize Aerobic Metabolism

- Why is a precision temperature control system critical for UFG 304L stainless steel irradiation experiments?

- What are the stages of an electric arc furnace? The Complete Tap-to-Tap Cycle Explained

- What is hot isostatic pressing in powder metallurgy? Achieve Full Density for Superior Performance

- What role does a laboratory drying oven play in zeolite membrane preparation? Ensure Structural Integrity & Success

- What are the different types of ash test? Choose the Right Method for Your Material

- Why is temperature excursion alarming important in ultra-low freezers? Protect Your Valuable Samples from Catastrophic Loss