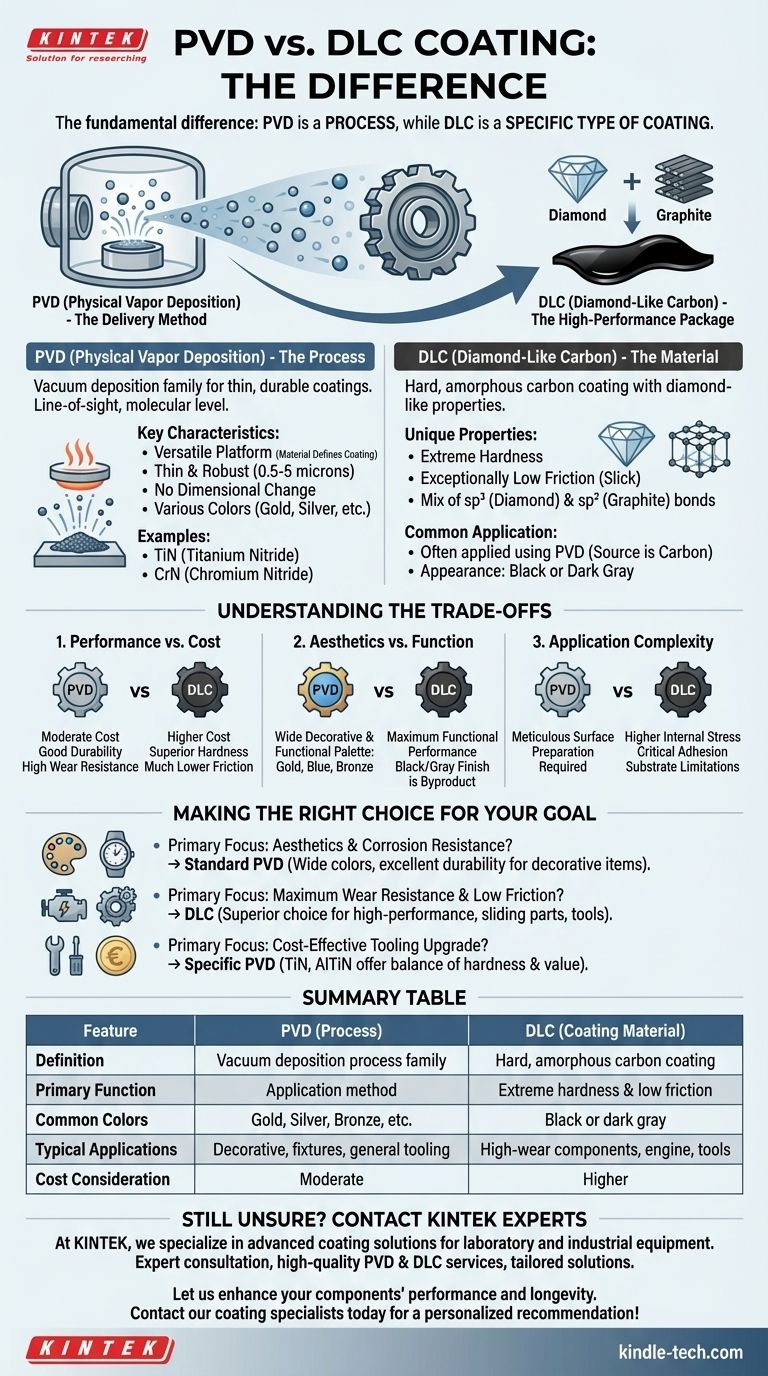

The fundamental difference is that Physical Vapor Deposition (PVD) is a process, while Diamond-Like Carbon (DLC) is a specific type of coating. In fact, the PVD process is one of the most common ways to apply a DLC coating. Think of PVD as the "delivery method" and DLC as one of the specialized "packages" that can be delivered.

While people often compare them, PVD and DLC are not mutually exclusive. The correct distinction is between PVD as a broad application technology and DLC as a high-performance carbon-based material that is often applied using that PVD technology.

What is PVD (Physical Vapor Deposition)?

PVD describes a family of vacuum deposition processes used to create thin, highly durable coatings. It is a line-of-sight process that takes place at the molecular level inside a vacuum chamber.

The General Process

Imagine spray painting, but instead of liquid paint, you are using a vapor of atoms. A solid source material—such as titanium, chromium, or carbon—is vaporized through methods like heating or ion bombardment.

This vapor then travels through the vacuum and condenses onto the part you want to coat, forming a very thin, dense, and strongly bonded film.

Key Characteristics of PVD

PVD is a versatile platform technology. The "PVD" label itself doesn't tell you the coating's material, only how it was applied.

The resulting film is a thin but robust protective layer, typically between 0.5 and 5 microns thick. This provides excellent wear and corrosion resistance without changing the part's dimensions or tolerances.

Because many different source materials can be used, PVD can produce coatings in a wide variety of colors and with different properties. Common PVD coatings include Titanium Nitride (TiN), which is gold-colored, and Chromium Nitride (CrN), which is silver-colored.

What is DLC (Diamond-Like Carbon)?

DLC is a specific class of hard, amorphous carbon material used for high-performance coatings. Its name comes from the fact that it exhibits some of the valuable properties of natural diamond.

The Unique Properties of DLC

The defining features of DLC are its extreme hardness and exceptionally low coefficient of friction. In simple terms, it's both incredibly hard-wearing and very "slick."

This unique combination comes from its atomic structure, which contains a mix of diamond-type (sp³) and graphite-type (sp²) carbon bonds. The ratio of these bonds determines its exact properties.

The PVD-DLC Connection

While other methods exist (like PACVD), PVD is a primary technique used to apply DLC coatings. In this scenario, the "source material" vaporized in the PVD process is carbon. The result is a specific, high-performance coating we call DLC, which is almost always black or dark gray in appearance.

Understanding the Trade-offs

Choosing between a standard PVD coating and a DLC coating involves clear trade-offs tied to performance needs and budget.

Performance vs. Cost

A standard PVD coating like Titanium Nitride (TiN) offers a significant improvement in hardness and wear resistance at a moderate cost.

DLC coatings provide superior hardness and, critically, a much lower friction surface. This extra performance comes at a significantly higher cost due to the more complex deposition process.

Aesthetics vs. Function

If your primary goal is a specific color (gold, blue, bronze, etc.) combined with good durability, a standard PVD coating is the correct choice. PVD offers a wide decorative and functional palette.

If your goal is maximum functional performance—especially for sliding parts or high-wear components where slickness is paramount—the black or gray finish of DLC is a byproduct of its superior function.

Application Complexity

Applying any PVD coating requires meticulous surface preparation. However, the high internal stress in some DLC films makes proper adhesion even more critical and challenging. DLC may not be suitable for all substrate materials or geometries.

Making the Right Choice for Your Goal

To select the right finish, you must define your primary objective.

- If your primary focus is aesthetics and corrosion resistance: A standard PVD coating offers a wide range of colors and textures with excellent durability for watches, fixtures, and decorative items.

- If your primary focus is maximum wear resistance and low friction: DLC is the superior choice, essential for high-performance applications like engine components, cutting tools, and firearm internals.

- If your primary focus is a cost-effective tooling upgrade: A specific PVD coating like TiN or AlTiN (Aluminum Titanium Nitride) is often the industry standard, providing a fantastic balance of hardness and value.

Ultimately, choosing correctly means matching the unique strengths of a specific coating material to the precise demands of your application.

Summary Table:

| Feature | PVD (Process) | DLC (Coating Material) |

|---|---|---|

| Definition | A family of vacuum deposition processes | A specific class of hard, amorphous carbon coating |

| Primary Function | Application method for various coatings | Extreme hardness and low friction surface |

| Common Colors | Gold (TiN), Silver (CrN), Bronze, etc. | Black or dark gray |

| Typical Applications | Decorative items, fixtures, general tooling | High-wear components, engine parts, cutting tools |

| Cost Consideration | Moderate cost for good durability | Higher cost for superior performance |

Still unsure which coating is right for your application?

At KINTEK, we specialize in advanced coating solutions for laboratory and industrial equipment. Whether you need the decorative durability of a standard PVD coating or the extreme performance of a DLC finish, our experts can help you select the perfect solution for your specific needs.

We provide:

- Expert consultation on coating selection

- High-quality PVD and DLC coating services

- Solutions tailored to your budget and performance requirements

Let us enhance your components' performance and longevity. Contact our coating specialists today for a personalized recommendation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating