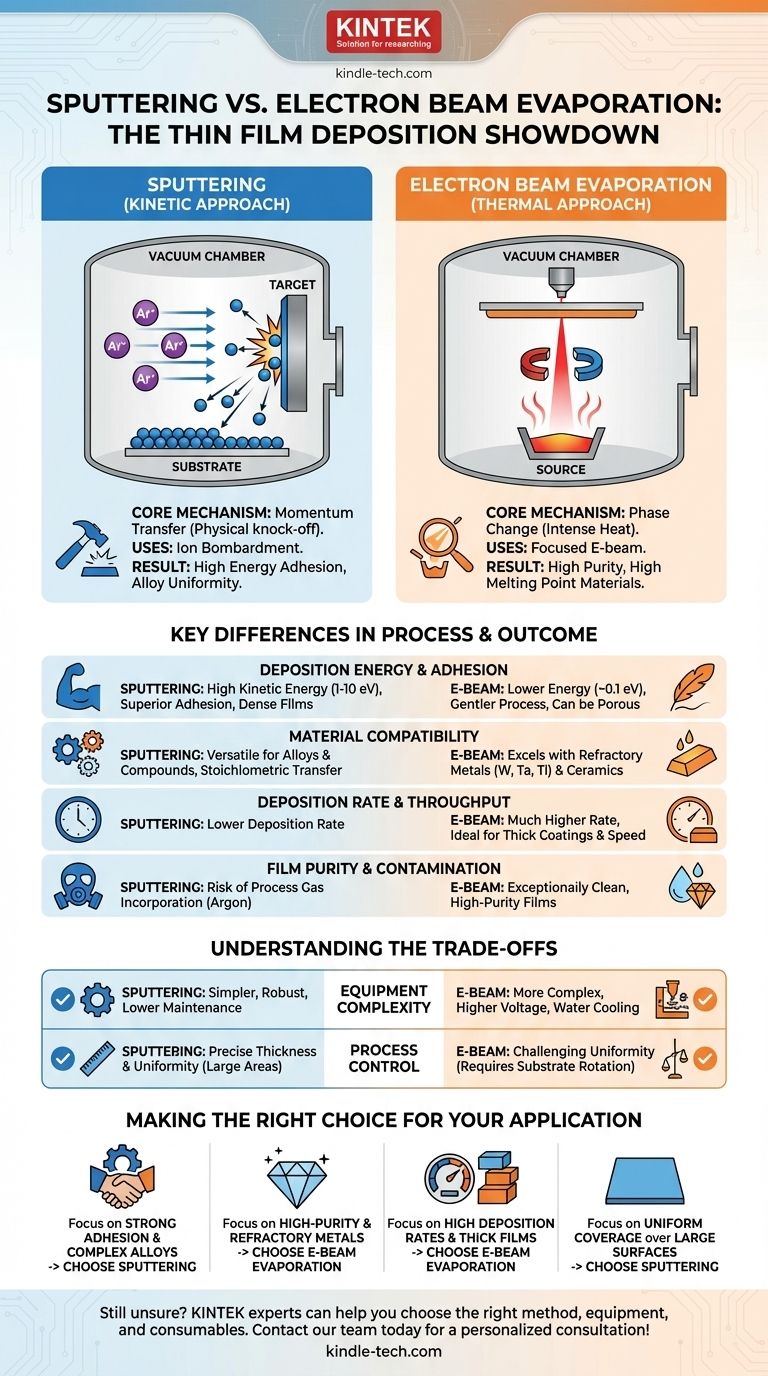

In essence, the primary difference lies in how atoms are liberated from a source material. Sputtering is a kinetic process that uses ion bombardment to physically knock atoms off a target, much like a sandblaster. Electron beam (e-beam) evaporation is a thermal process that uses a focused beam of electrons to heat a material until it boils and turns into a vapor.

The core distinction is one of force versus heat. Sputtering uses momentum transfer for a more energetic deposition that excels in adhesion and alloy uniformity, while e-beam evaporation uses thermal energy for a cleaner, faster deposition ideal for high-purity, high-melting-point materials.

The Core Mechanism: Momentum vs. Heat

To choose the right method, you must first understand their fundamentally different physical principles. One is a mechanical collision, the other is a phase change driven by intense heat.

How Sputtering Works (The Kinetic Approach)

Sputtering begins by introducing an inert gas, typically argon, into a vacuum chamber and creating a plasma.

An electric field accelerates these positively charged argon ions towards the source material, known as the target.

Upon impact, the energetic ions transfer their momentum to the target atoms, knocking them loose. These ejected atoms then travel through the chamber and coat the substrate, forming a thin film.

How E-Beam Evaporation Works (The Thermal Approach)

In an e-beam system, a high-intensity beam of electrons is generated from a hot filament.

Powerful magnets steer and focus this beam onto a small spot within a crucible containing the source material.

The immense energy from the electron beam rapidly heats the material past its melting and boiling points, causing it to evaporate. This vapor rises through the vacuum chamber and condenses on the cooler substrate, forming the film.

Key Differences in Process and Outcome

The choice between these two methods has significant consequences for the final film's properties, the materials you can use, and the overall efficiency of your process.

Deposition Energy & Film Adhesion

Sputtered atoms have significantly higher kinetic energy (typically 1-10 eV) compared to evaporated atoms (around 0.1 eV).

This high energy helps atoms physically embed into the substrate surface, resulting in denser films with superior adhesion. E-beam deposition is a gentler process, which can be an advantage for delicate substrates.

Material Compatibility

E-beam evaporation excels at depositing materials with very high melting points, such as tungsten, tantalum, and titanium, as well as ceramics and optical dielectrics that are difficult or impossible to sputter effectively.

Sputtering is more versatile for creating films from alloys or compounds. Because the atoms are knocked off mechanically, the composition of the deposited film is much more likely to match the composition of the source target.

Deposition Rate & Throughput

For most materials, e-beam evaporation offers a much higher deposition rate than sputtering.

This makes it the preferred method for applying thick coatings or in high-throughput industrial applications where speed is a critical factor.

Film Purity & Contamination

Because it only heats the source material in a high vacuum, e-beam evaporation is an exceptionally clean process that produces very high-purity films.

In sputtering, there is a small but real risk of the process gas (argon) becoming embedded or incorporated into the growing film, which can be undesirable in certain high-purity applications like semiconductor manufacturing.

Understanding the Trade-offs

Neither method is universally superior. The optimal choice depends on balancing equipment complexity, process control, and potential drawbacks.

Equipment Complexity and Cost

Sputtering systems can be relatively simple and robust, often requiring minimal maintenance. They are well-suited for reliable, repeatable coatings over large areas.

E-beam systems are generally more complex. They require high-voltage power supplies, powerful electromagnets for beam control, and water-cooling systems for the crucible, which can increase both initial cost and maintenance requirements.

Substrate Heating

Both processes can heat the substrate, but through different mechanisms.

The plasma in a sputtering chamber radiates heat and can cause significant substrate heating. In e-beam, the primary source of heat is radiation from the molten source material in the crucible. The best choice often depends on which type of heat transfer is more manageable for a given substrate.

Process Control

Sputtering generally offers more straightforward and precise control over film thickness and uniformity, especially over large or complexly shaped substrates.

Achieving high uniformity with e-beam evaporation can be more challenging and often requires complex substrate rotation and careful source placement.

Making the Right Choice for Your Application

Your final decision should be guided by the specific requirements of your material and the desired properties of your thin film.

- If your primary focus is strong film adhesion and depositing complex alloys: Sputtering is the superior choice due to its high-energy deposition and stoichiometric transfer.

- If your primary focus is high-purity films of refractory metals or optical coatings: Electron beam evaporation provides the cleanliness and thermal energy needed for these demanding materials.

- If your primary focus is high deposition rates for thick films: Electron beam evaporation's speed and efficiency make it the clear leader for throughput.

- If your primary focus is achieving uniform coverage over large, intricate surfaces: Sputtering often provides a more controllable and inherently uniform coating solution.

Ultimately, selecting the correct deposition method requires a clear understanding of your end goal and the physical principles that will get you there.

Summary Table:

| Feature | Sputtering | Electron Beam Evaporation |

|---|---|---|

| Core Mechanism | Kinetic (Momentum Transfer) | Thermal (Heating/Vaporization) |

| Primary Advantage | Superior Adhesion, Alloy Uniformity | High Purity, High Melting Point Materials |

| Deposition Rate | Lower | Higher |

| Film Density | High (Dense Films) | Lower (Can be porous) |

| Ideal For | Alloys, Complex Shapes, Strong Adhesion | Refractory Metals, Optical Coatings, Thick Films |

Still unsure which thin film deposition method is right for your application? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables for your specific laboratory needs, whether you're working with sputtering targets or e-beam evaporation sources. Let us help you achieve the perfect coating for your project. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is bio-oil in biomass? A Guide to the Liquid Fuel from Pyrolysis

- What role do thermostatic shakers and Erlenmeyer flasks play in bioconversion? Optimize Your Xylose to Xylitol Process

- What is the purpose of using an ultrasonic cleaner or dispersion instrument? Boost Photocatalytic CO2 Reduction Efficiency

- Why is argon gas used in sputtering? For High-Purity, Efficient Thin Film Deposition

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- Why is it necessary to use an industrial drying oven for sludge torrefaction? Ensure Data Integrity and Efficiency

- Does annealing strengthen a material? Why Softening is Key to Better Manufacturing

- What role do high-pressure homogenizers or ultrasonic cell disrupters play in the mechanical processing of nanocellulose?