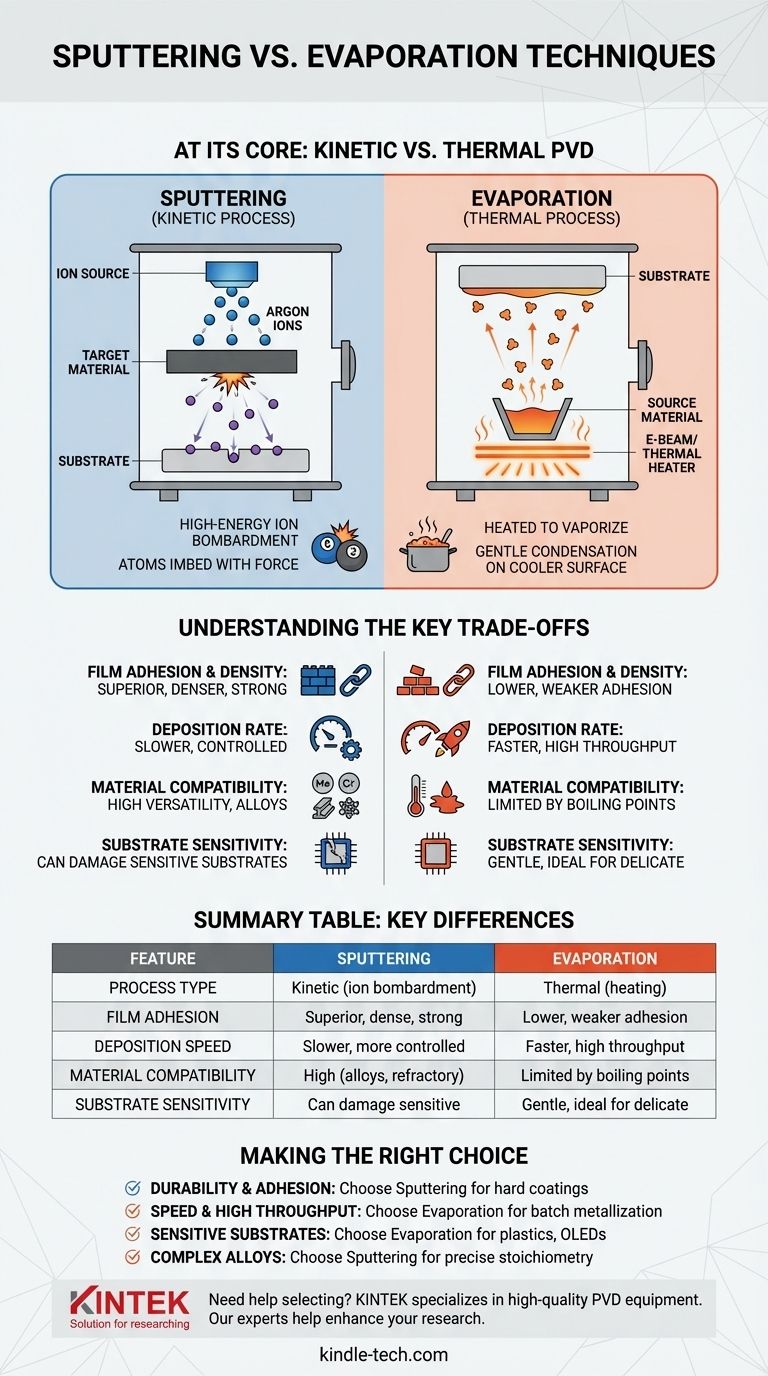

At its core, the difference is kinetic versus thermal. Sputtering is a physical process where high-energy ions bombard a target material, kinetically knocking atoms loose like microscopic billiard balls. Evaporation is a thermal process where a source material is heated in a vacuum until it boils, creating a vapor that condenses onto a cooler substrate, much like steam condensing on a cold mirror.

Choosing between them is a fundamental trade-off. Sputtering generally produces denser, more adhesive films and can handle a wider range of materials, but it is slower. Evaporation is faster and gentler on the substrate but often results in less durable films with weaker adhesion.

Understanding the Core Mechanisms

Both sputtering and evaporation are forms of Physical Vapor Deposition (PVD), meaning they physically transfer material onto a surface without a chemical reaction. However, how they generate that vaporized material is fundamentally different, which dictates the final properties of the film.

Evaporation: A Thermal Process

In thermal or e-beam evaporation, the source material is placed in a high-vacuum chamber and heated until its atoms or molecules gain enough thermal energy to vaporize.

This vapor travels through the vacuum and condenses on the target substrate, which is kept at a lower temperature, forming the thin film.

The atoms arrive at the substrate with relatively low kinetic energy. Think of it as a cloud of steam gently condensing on a surface.

Sputtering: A Kinetic Process

Sputtering does not rely on heat to vaporize the material. Instead, it creates a plasma from an inert gas (usually argon) inside a low-vacuum chamber.

An electric field accelerates these argon ions, causing them to collide with the source material (the "target") with immense force.

These collisions physically eject, or "sputter," atoms from the target. These ejected atoms travel and deposit onto the substrate with high kinetic energy, essentially embedding themselves into the surface.

How Mechanism Dictates Film Properties

The difference between a low-energy "condensation" and a high-energy "bombardment" has significant consequences for the final thin film.

Film Adhesion and Density

Sputtering produces films with superior adhesion. The high energy of the sputtered atoms causes them to physically impact and intermix with the top layer of the substrate, creating a strong, graded interface.

Evaporated films typically have lower adhesion because the low-energy atoms simply rest on the substrate surface with weaker Van der Waals forces.

Consequently, sputtered films are also denser and less porous, as the energetic atoms arrange themselves more tightly upon arrival.

Deposition Rate and Control

Evaporation generally offers a much higher deposition rate. Heating a material to its boiling point can produce a large volume of vapor quickly, making it ideal for depositing thick layers or for high-throughput manufacturing.

Sputtering is a slower, more controlled process. The rate of deposition is directly tied to the ion current and voltage, allowing for precise control over film thickness, which is critical for complex optical or electronic devices.

Film Purity and Structure

Because evaporation occurs in a high vacuum, it can produce very pure films, especially for single elements.

Sputtering operates in a low-pressure gas environment, and some of the inert sputtering gas (argon) can become entrapped in the growing film. This can induce compressive stress in the film.

The high-energy nature of sputtering also results in a finer, smaller grain structure, while the lower-energy deposition of evaporation leads to larger grains.

Understanding the Key Trade-offs

Neither technique is universally better; the choice is driven by the specific requirements of your application.

Quality vs. Speed

The most common trade-off is film quality versus deposition speed. If your primary need is a durable, dense, and highly adhesive coating, sputtering is often the superior choice despite being slower.

If speed and throughput are the priority for a simpler metallization layer, evaporation is far more efficient.

Material Compatibility

Sputtering is exceptionally versatile. It can deposit virtually any material, including high-temperature refractory metals, insulators, and complex alloys, because it doesn't rely on melting points. The composition of a sputtered alloy film is typically identical to the target.

Evaporation struggles with materials that have very high boiling points. It can also be problematic for alloys, as the constituent elements may have different vapor pressures, causing them to evaporate at different rates and altering the film's final composition.

Substrate Sensitivity

The high-energy bombardment in sputtering can damage sensitive substrates, such as plastics or organic electronic materials (like OLEDs).

Evaporation is a much gentler process. The low thermal load and low kinetic energy of the arriving atoms make it the ideal choice for coating delicate or heat-sensitive substrates.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your project's non-negotiable requirements.

- If your primary focus is durability and adhesion: Choose sputtering for its dense, well-adhered films, ideal for hard coatings on tools or high-performance optical filters.

- If your primary focus is speed and high throughput: Choose evaporation for its rapid deposition rates, suitable for applications like batch metallization on solar panels or glass.

- If your primary focus is depositing on sensitive substrates: Choose evaporation for its gentle, low-energy process, which is essential for plastics and organic electronics like OLEDs.

- If your primary focus is depositing complex alloys or compounds: Choose sputtering for its ability to maintain the target's stoichiometry, ensuring the composition of your film is correct.

By understanding these fundamental differences, you can confidently select the deposition technique that aligns perfectly with your material, substrate, and performance requirements.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Process Type | Kinetic (ion bombardment) | Thermal (heating to vaporize) |

| Film Adhesion | Superior, dense, and strong | Lower, weaker adhesion |

| Deposition Speed | Slower, more controlled | Faster, high throughput |

| Material Compatibility | High (alloys, refractory metals) | Limited by boiling points |

| Substrate Sensitivity | Can damage sensitive substrates | Gentle, ideal for delicate materials |

Need help selecting the right deposition technique for your lab's specific requirements? At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your Physical Vapor Deposition (PVD) needs. Whether you require the superior adhesion of sputtering or the high-speed throughput of evaporation, our experts can help you choose the perfect solution to enhance your research or production outcomes. Contact us today to discuss your project and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained