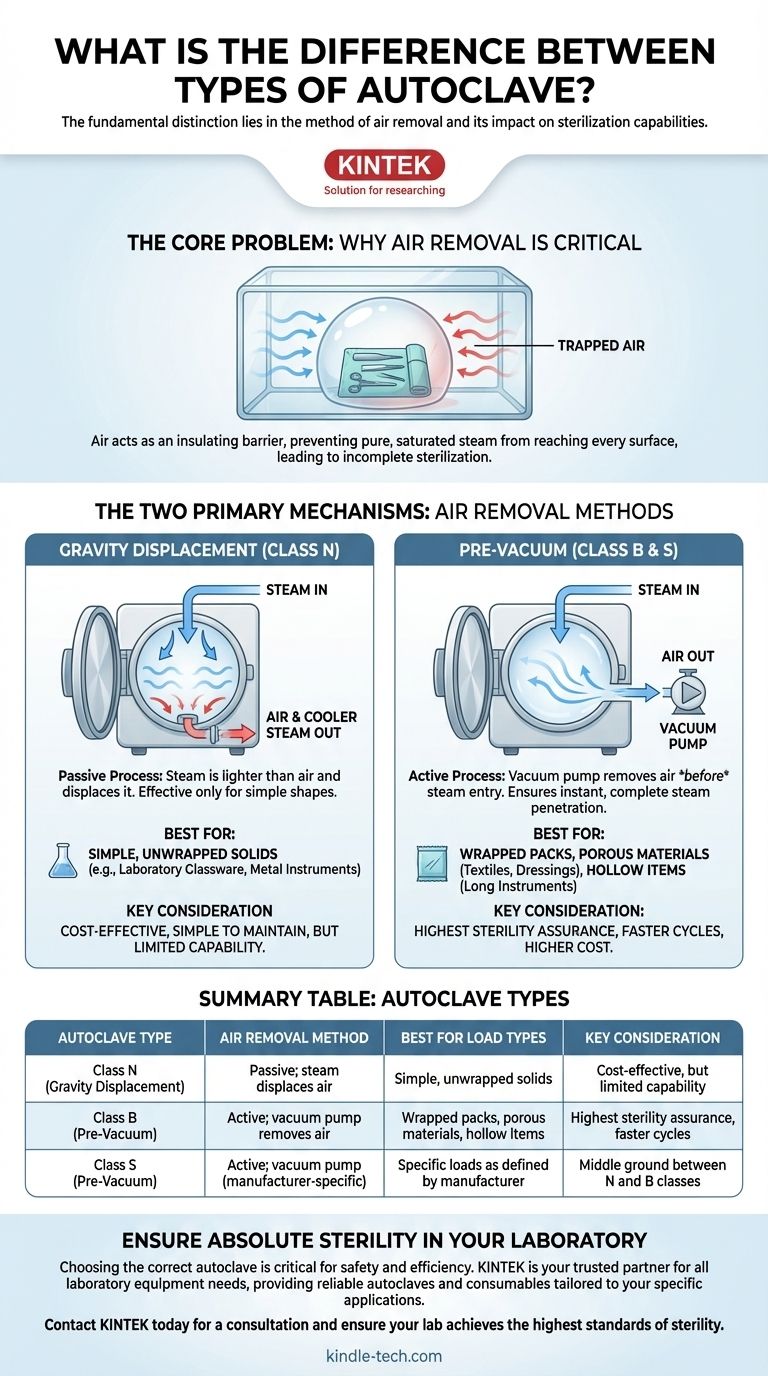

The fundamental difference between autoclave types lies in their method of air removal, which directly impacts their ability to sterilize different kinds of materials. While they vary in size and operation, the core distinction is between passive gravity displacement systems and active vacuum-assisted systems.

The critical takeaway is that an autoclave's classification is not about its size, but about its efficiency in removing air from the chamber. Trapped air is the primary obstacle to effective steam sterilization, and different autoclave types solve this problem with varying levels of sophistication and cost.

The Core Problem: Why Air Removal is Critical

Every autoclave must achieve one essential goal: ensure that pure, saturated steam makes direct contact with every surface of the items being sterilized. The presence of air pockets prevents this contact, leading to incomplete sterilization.

The Impact of Trapped Air

Air acts as an insulating barrier, preventing steam from reaching the required temperature and pressure to kill microorganisms.

This is especially problematic with complex items like surgical textiles, hollow instruments, or wrapped instrument packs, where air can easily become trapped inside.

The Two Primary Mechanisms

To solve this, autoclaves use one of two fundamental methods for removing air before the sterilization phase begins. This difference in mechanism is what defines the primary types.

The Primary Autoclave Types Explained

The classification of autoclaves, often designated by letters like N, S, and B, directly relates to their air removal method and the complexity of the loads they can safely process.

Gravity Displacement Autoclaves (Class N)

This is the simplest and most common type of autoclave, often used in laboratory settings.

It operates on the principle that steam is lighter than air. As steam is fed into the chamber, it fills the upper areas and displaces the cooler, denser air, forcing it down and out through a drain vent.

Because this process is passive, it is less effective at removing air from complex shapes. Therefore, Class N autoclaves are only suitable for sterilizing simple, unwrapped, solid items like basic lab glassware or metal instruments.

Pre-Vacuum Autoclaves (Class B & Class S)

These more advanced systems use a vacuum pump to actively remove air before steam is introduced. This process is often called pre-vacuum or vacuum-induced sterilization.

By creating a vacuum, the system ensures there are no air pockets left, allowing steam to penetrate dense and complex loads instantly and completely.

Class B autoclaves represent the highest standard. They use a series of vacuum and pressure pulses to reliably remove air from the most challenging loads, including porous materials (gowns, dressings) and long, hollow instruments.

Class S autoclaves are designed for specific load types as defined by the manufacturer and use a vacuum pump, but may not have the same broad capability as a Class B unit. They are a middle ground between N and B.

Understanding the Trade-offs

Choosing the right autoclave requires balancing capability against cost and complexity. The most advanced system is not always the most appropriate.

Cost vs. Capability

Gravity displacement (Class N) systems are significantly less expensive and simpler to maintain.

Pre-vacuum (Class B) systems are more expensive due to the addition of a vacuum pump and more complex controls, but they offer far greater versatility and assurance of sterility for all load types.

Cycle Speed and Efficiency

Pre-vacuum cycles are considerably faster. Actively removing air is more efficient than waiting for passive displacement, which reduces overall cycle time and increases throughput.

Load Complexity Determines the Need

The single most important factor is the nature of the items you need to sterilize. Attempting to sterilize a wrapped surgical kit in a Class N gravity autoclave poses a significant risk of failure.

Making the Right Choice for Your Goal

Your selection must be based on the most challenging items you intend to process.

- If your primary focus is sterilizing unwrapped, solid items like glassware or simple tools: A Gravity Displacement (Class N) autoclave is a cost-effective and suitable choice.

- If your primary focus is sterilizing wrapped instruments, porous textiles, or hollow items for medical use: A Pre-Vacuum (Class B) autoclave is essential to guarantee complete steam penetration and sterility.

- If your primary focus is industrial curing of composites or vulcanizing rubber: You will need a specialized industrial autoclave designed for specific material processing, which operates on similar principles but is built for different applications than medical sterilization.

Ultimately, understanding how an autoclave removes air empowers you to choose the correct tool for ensuring absolute sterility.

Summary Table:

| Autoclave Type | Air Removal Method | Best For Load Types | Key Consideration |

|---|---|---|---|

| Class N (Gravity Displacement) | Passive; steam displaces air | Simple, unwrapped solids (e.g., glassware) | Cost-effective, but limited capability |

| Class B (Pre-Vacuum) | Active; vacuum pump removes air | Wrapped packs, porous materials, hollow items | Highest sterility assurance, faster cycles |

| Class S (Pre-Vacuum) | Active; vacuum pump (manufacturer-specific) | Specific loads as defined by manufacturer | Middle ground between N and B classes |

Ensure Absolute Sterility in Your Laboratory

Choosing the correct autoclave is critical for the safety and efficiency of your operations. Whether you process simple glassware or complex, wrapped surgical kits, the right equipment guarantees effective sterilization.

KINTEK is your trusted partner for all laboratory equipment needs. We specialize in providing reliable autoclaves and consumables tailored to your specific applications, from research labs to clinical settings.

Let us help you select the perfect autoclave to protect your work, your samples, and your team. Our experts are ready to provide personalized recommendations based on your load types and throughput requirements.

Contact KINTEL today for a consultation and ensure your lab achieves the highest standards of sterility.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?