In short, the diameter of the grinding balls is a critical control parameter in milling. Smaller balls are more effective for grinding fine particles due to their greater surface area, while larger balls are necessary for breaking down coarse particles because they deliver higher impact energy. This choice directly dictates the efficiency of the process and the final quality of the ground material.

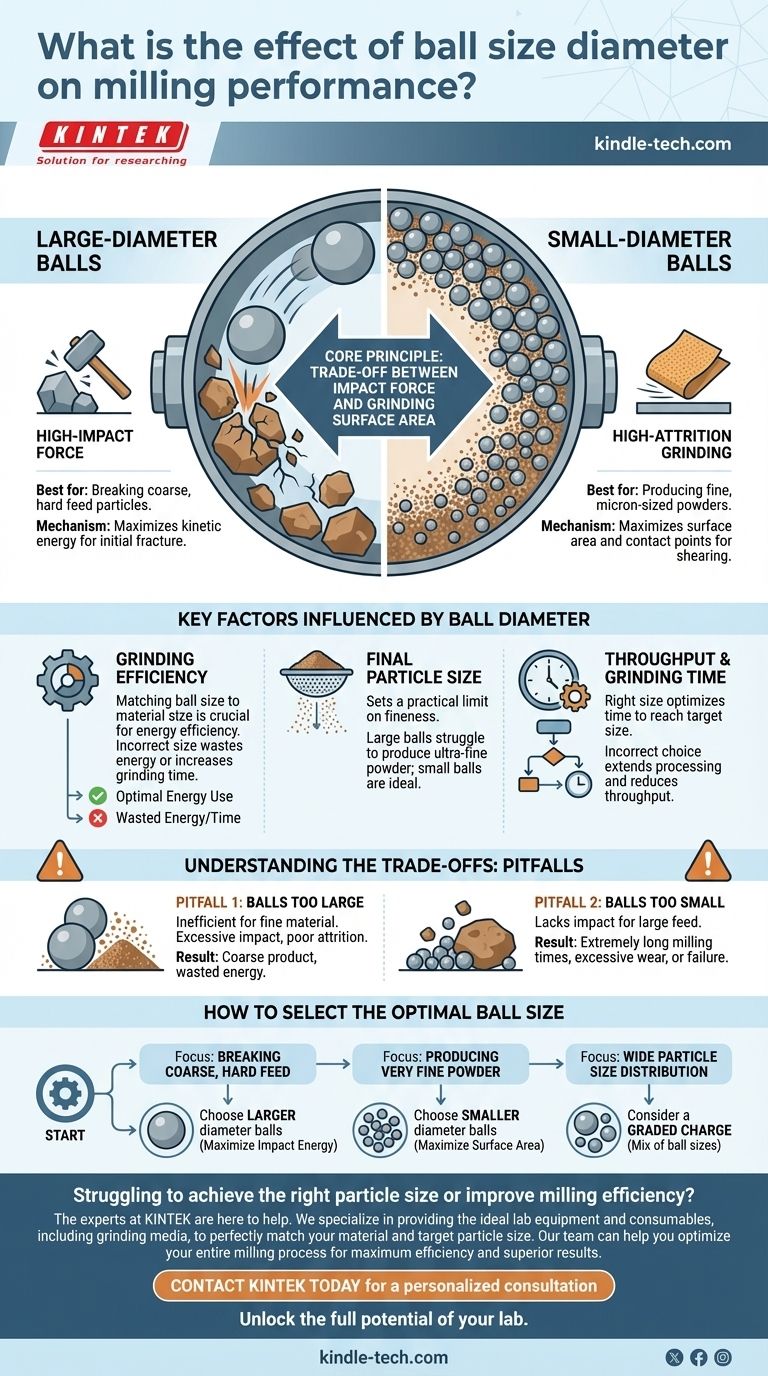

The core principle is a trade-off between impact force and grinding surface area. Selecting the optimal ball size requires matching the grinding media to the initial size of the material you are processing and the final particle size you wish to achieve.

The Physics of Grinding: Impact vs. Attrition

The effectiveness of a ball mill relies on two primary mechanisms: impact and attrition. The diameter of the grinding media directly determines which of these forces will dominate the process.

The Role of Large-Diameter Balls

Larger balls possess greater individual mass. As the mill rotates, this mass translates into higher kinetic energy, resulting in a powerful impact force when the balls strike the material.

This high-impact energy is essential for the initial stages of grinding, where the primary goal is to fracture large, coarse, and often hard feed particles. Think of it as using a sledgehammer to break a large rock into smaller pieces.

The Power of Small-Diameter Balls

A charge of smaller balls has a significantly higher total surface area and creates vastly more contact points than an equal volume of larger balls.

This configuration is ideal for attrition grinding, where particles are ground down by the shearing and rubbing action between the numerous balls. This is the mechanism required to produce very fine, micron-sized powders from material that is already relatively small. This is more akin to using sandpaper to smooth a surface.

Key Factors Influenced by Ball Diameter

Choosing the correct ball size is not just a theoretical exercise; it has direct, measurable effects on the performance and economics of your milling operation.

Grinding Efficiency

Matching the ball size to the material size is paramount for energy efficiency. Using balls that are too large for fine grinding wastes energy in heat and noise without effectively reducing particle size. Conversely, using balls that are too small for coarse material results in long, inefficient grinding times.

Final Particle Size

The diameter of the grinding media sets a practical limit on the fineness of the final product. A charge of large balls will struggle to produce an ultra-fine powder, while a charge of small balls is specifically suited for that purpose.

Throughput and Grinding Time

The right ball size optimizes the time required to reach the target particle size. An incorrect choice extends processing time, reduces equipment throughput, and increases operational costs.

Understanding the Trade-offs

There is no single "best" ball size; the optimal choice is always a function of the application. Misunderstanding this leads to common and costly inefficiencies.

Pitfall 1: Using Balls That Are Too Large

When grinding already fine material, large balls are highly inefficient. Their impact energy is excessive, and the limited number of contact points provides poor attrition, leading to a coarse final product and wasted energy.

Pitfall 2: Using Balls That Are Too Small

When attempting to grind large, coarse feed, small balls lack the necessary impact energy to cause fractures. This results in extremely long milling times, excessive wear on the media, or a complete failure to grind the material effectively.

The Interplay with Other Variables

Ball diameter does not exist in a vacuum. Its effect is deeply connected to other critical parameters, including the mill's rotational speed, the material's hardness, and the mill's filling ratio. A truly optimized process considers how all these factors work in concert.

How to Select the Optimal Ball Size

Your decision should be guided by a clear understanding of your starting material and your desired outcome.

- If your primary focus is breaking down coarse, hard feed material: Choose larger diameter balls to maximize the impact energy needed for initial fracture.

- If your primary focus is producing a very fine powder from smaller particles: Use smaller diameter balls to maximize the surface area and points of contact required for attrition grinding.

- If you need to process a material with a wide particle size distribution: Consider a graded charge, which is a mix of different ball sizes, to handle both coarse and fine particles simultaneously.

Ultimately, selecting the correct ball size is one of the most powerful levers you can pull to control the efficiency and outcome of your milling process.

Summary Table:

| Ball Size | Primary Mechanism | Best For | Key Advantage |

|---|---|---|---|

| Large Diameter | High-Impact Force | Breaking coarse, hard feed particles | Delivers maximum kinetic energy for initial fracture |

| Small Diameter | High-Attrition Grinding | Producing fine, micron-sized powders | Maximizes surface area and contact points for shearing |

Struggling to achieve the right particle size or improve your milling efficiency? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables, including grinding media, to perfectly match your material and target particle size. Our team can help you optimize your entire milling process for maximum efficiency and superior results.

Contact KINTEL today for a personalized consultation and let us help you unlock the full potential of your lab.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis