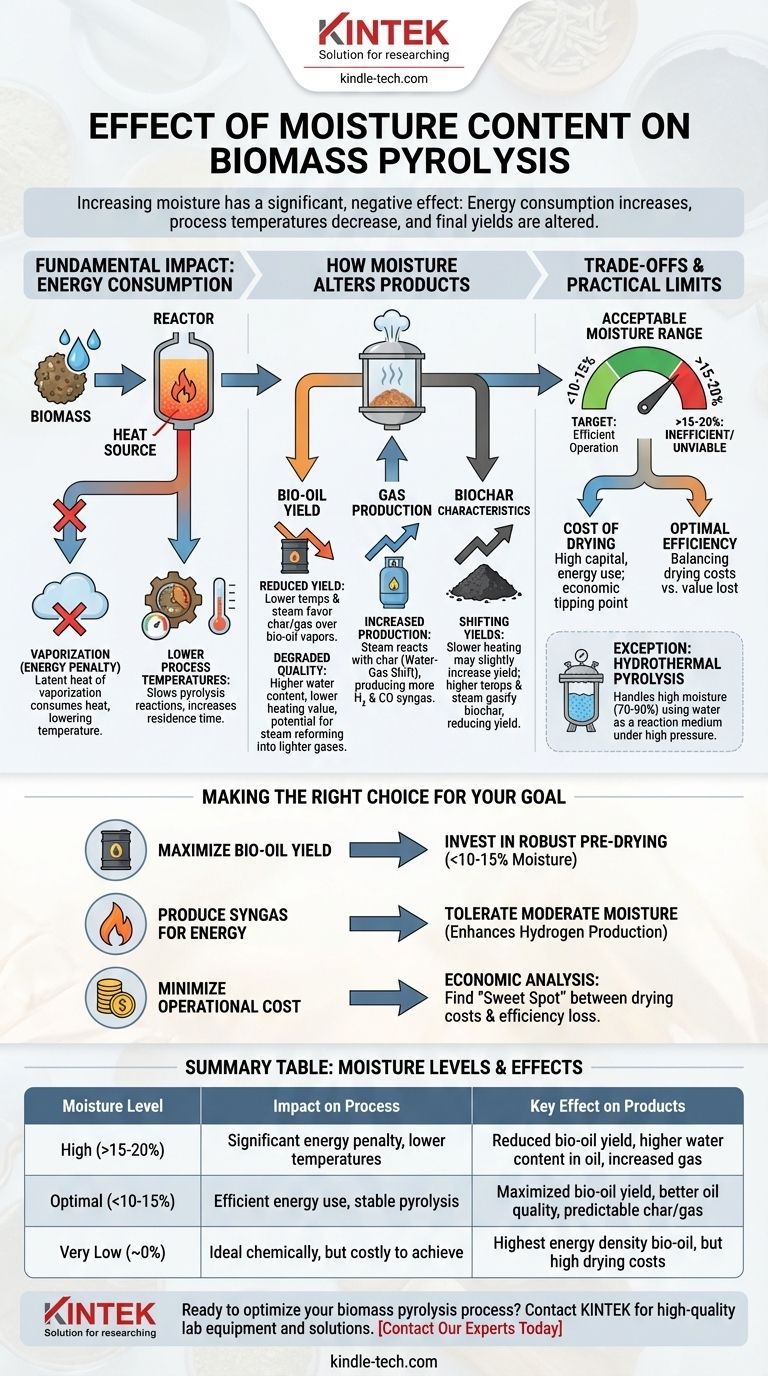

In short, increasing moisture content in biomass has a significant, and generally negative, effect on the pyrolysis process. Fundamentally, any water present must be heated and vaporized into steam before the biomass itself can break down. This consumes a substantial amount of energy, lowers the overall process temperature, and ultimately alters the final yields and quality of the bio-oil, biochar, and gas produced.

The core issue is that moisture acts as a major energy sink and a secondary reactant within the pyrolysis reactor. Effectively managing the moisture content of your feedstock is not a minor optimization—it is a critical prerequisite for achieving an efficient, stable, and predictable thermochemical conversion process.

The Fundamental Impact: Energy Consumption

The most immediate and unavoidable effect of moisture is on the energy balance of the pyrolysis reactor. This primary effect causes several downstream consequences.

The Energy Penalty of Vaporization

Water has a high latent heat of vaporization, meaning it requires a large amount of energy to convert from a liquid to steam.

This energy, often called the "energy penalty," is drawn directly from the heat source of the reactor. It is effectively wasted energy, as it is used to boil water rather than to break down the biomass structure.

Lowering Process Temperature

Because a portion of the input heat is diverted to vaporize water, the overall temperature achieved within the reactor is lower than it would be with dry feedstock.

Lower process temperatures slow down the primary pyrolysis reactions. This can significantly reduce the throughput of the system, as the biomass requires a longer residence time to fully convert.

How Moisture Alters Pyrolysis Products

Beyond the energy penalty, the presence of steam within the reactor actively changes the chemical reaction pathways, directly impacting the final product distribution.

Reduced Bio-oil Yield

For most pyrolysis operations, maximizing the liquid bio-oil is the primary goal. Moisture works directly against this objective.

Lower reaction temperatures and the presence of steam favor the formation of char and non-condensable gases over the condensable organic vapors that form bio-oil.

Degraded Bio-oil Quality

The bio-oil that is produced will be of lower quality. It will inherently have a higher water content, which lowers its heating value (energy density) and can make it more corrosive and unstable.

Furthermore, the steam can promote secondary reactions, such as steam reforming, which crack the valuable heavy organic molecules into lighter, less useful gases and more water.

Increased Gas Production

The steam generated from the moisture is not inert; it can react with the biomass and biochar at high temperatures.

Reactions like the water-gas shift and steam reforming consume char and organic vapors to produce more hydrogen (H₂) and carbon monoxide (CO). This increases the yield of non-condensable syngas at the expense of the desired bio-oil and biochar.

Shifting Biochar Characteristics

In general, the slower heating rates and lower temperatures caused by moisture tend to slightly increase biochar yield.

However, at higher temperatures, the steam becomes reactive enough to gasify the biochar, which would then decrease the final char yield. The precise effect depends heavily on the reactor conditions.

Understanding the Trade-offs and Practical Limits

While zero moisture is ideal from a chemical perspective, it is not practical or economical from an operational one.

The Cost of Drying

Pre-drying biomass to very low moisture levels requires significant capital investment in drying equipment and consumes a large amount of energy.

There is an economic tipping point where the cost of further drying outweighs the efficiency gains you achieve in the pyrolysis reactor.

The "Acceptable" Moisture Range

Most commercial pyrolysis systems are designed to handle some level of moisture. As a general rule, a feedstock moisture content of less than 10-15% by weight is considered the target for efficient operation.

Above 15-20%, the negative effects on energy consumption and product yield become increasingly severe, often rendering the process inefficient or economically unviable.

The Exception: Hydrothermal Pyrolysis

It is critical to distinguish conventional (fast) pyrolysis from hydrothermal pyrolysis (or liquefaction).

Hydrothermal processes are specifically designed to handle very wet feedstock (70-90% moisture) by operating with water in its liquid or supercritical state under high pressure. In this context, water is an essential part of the reaction medium, not a contaminant.

Making the Right Choice for Your Goal

Your strategy for managing moisture depends entirely on your desired output.

- If your primary focus is maximizing liquid bio-oil yield: You must invest in robust pre-drying to reduce feedstock moisture to below 15%, and ideally below 10%.

- If your primary focus is producing syngas for energy or synthesis: A moderate moisture content can be tolerated and may even be slightly beneficial by enhancing hydrogen production through steam reforming.

- If your primary focus is minimizing operational cost: You must conduct an economic analysis to find the "sweet spot" between the cost of drying your specific feedstock and the value lost from reduced efficiency and lower-quality products.

Ultimately, mastering moisture control is the key to unlocking consistent and efficient biomass conversion.

Summary Table:

| Moisture Level | Impact on Process | Key Effect on Products |

|---|---|---|

| High (>15-20%) | Significant energy penalty, lower temperatures | Reduced bio-oil yield, higher water content in oil, increased gas |

| Optimal (<10-15%) | Efficient energy use, stable pyrolysis | Maximized bio-oil yield, better oil quality, predictable char/gas |

| Very Low (~0%) | Ideal chemically, but costly to achieve | Highest energy density bio-oil, but high drying costs |

Ready to optimize your biomass pyrolysis process? At KINTEK, we specialize in providing high-quality lab equipment and consumables to help you achieve precise moisture control and maximize your pyrolysis yields. Whether you're focused on bio-oil, syngas, or biochar production, our solutions are designed to enhance your lab's efficiency and accuracy. Contact our experts today to discuss your specific needs and discover how KINTEK can support your laboratory's success in biomass conversion.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is pyrolysis oil made of? A Deep Dive into Its Complex Chemical Composition

- What are the future prospects for pyrolysis? Transforming Waste into Renewable Fuels and Carbon Removal

- What are the challenges of large-scale biomass energy use? The Hidden Hurdles to a Green Energy Source

- What are the uses of furnace in laboratory? A Guide to Material Transformation & Analysis

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What is target in sputtering? The Essential Source Material for Thin-Film Deposition

- Why is DC sputtering used for metals? Unlock Faster, More Cost-Effective Metal Deposition