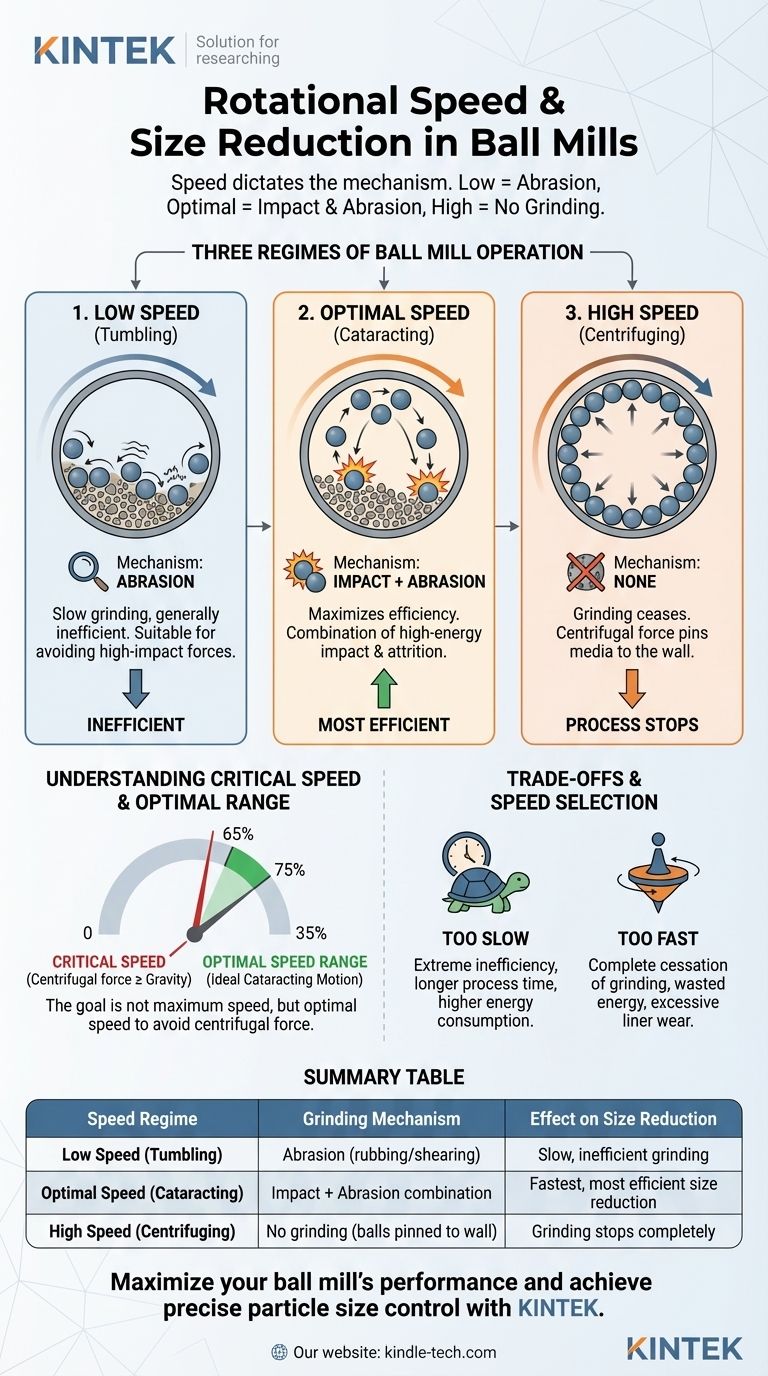

The speed of rotation is the most critical operational parameter in a ball mill, directly dictating the mechanism of size reduction. At low speeds, grinding occurs through abrasion as balls tumble over each other. As speed increases to an optimal point, a powerful impact mechanism is introduced as balls are lifted and fall onto the material. If the speed becomes too high, grinding ceases entirely as centrifugal force pins the balls to the mill's wall.

The goal is not to achieve the maximum possible speed, but to find the optimal speed. This speed, typically 65-75% of the "critical speed," creates a cascading and cataracting motion that maximizes the combination of impact and abrasion for the most efficient size reduction.

The Three Regimes of Ball Mill Operation

The effect of rotational speed on the grinding mechanism can be understood by breaking it down into three distinct operational regimes.

The Low-Speed Regime (Tumbling)

At low speeds, the grinding media is simply lifted a short distance up the side of the mill before it gently tumbles and slides back down.

The dominant size reduction mechanism here is abrasion, where particles are worn down by the rubbing and shearing action of the balls sliding against one another.

This regime results in very slow grinding and is generally inefficient, though it can be suitable for applications where high-impact forces must be avoided.

The Optimal Speed Regime (Cataracting)

As the speed increases, the balls are carried further up the mill wall, nearly to the top of the drum, before they detach and fall freely onto the material below.

This free-fall motion is known as cataracting, and it introduces a powerful impact force as the primary mechanism for breaking particles. Abrasion still occurs as the layers of balls shear against each other.

This combination of high-energy impact and continuous attrition provides the fastest and most efficient size reduction for the vast majority of materials.

The High-Speed Regime (Centrifuging)

If the rotational speed continues to increase, it will eventually reach what is known as the critical speed.

At this point, the centrifugal force pressing the balls against the mill wall becomes equal to or greater than the force of gravity pulling them down. The balls and material become pinned to the inner wall, rotating with the mill as a single mass.

In this state, there is no relative motion between the grinding media and the material, and therefore, size reduction stops completely.

Understanding Critical Speed

The concept of critical speed is fundamental to operating a ball mill effectively. It represents a theoretical maximum that you must operate below.

What is Critical Speed?

Critical speed is the rotational speed at which the innermost layer of grinding media will cling to the mill liner for a full revolution.

It is determined by the mill's internal diameter. A larger diameter mill will have a lower critical speed than a smaller diameter mill, as the balls have a longer distance to fall.

Why Optimal Speed is a Percentage

Productive grinding occurs within a specific range relative to the critical speed.

The industry standard for optimal performance is between 65% and 75% of the critical speed. This range provides the ideal trajectory for the balls, maximizing the impact energy generated as they fall without risking them being thrown too far and striking the opposite liner directly.

The Trade-offs of Speed Selection

Choosing a speed is not just about efficiency; it's about balancing outcomes and avoiding operational failures.

Risks of Operating Too Slowly

The primary consequence of operating at too low a speed is extreme inefficiency. The grinding process will take significantly longer, consuming more energy per unit of product. For harder materials, the abrasive forces may be insufficient to achieve the desired particle size at all.

Risks of Operating Too Fast

Operating too close to, or above, the critical speed results in a complete cessation of grinding, wasting time and energy. It also causes excessive wear on the mill liner as the media is held against it under high pressure, without performing any useful work.

Setting the Right Speed for Your Goal

Your choice of operating speed should be a deliberate decision based on the material you are processing and your desired outcome.

- If your primary focus is maximum grinding efficiency and throughput: Operate between 65% and 75% of the calculated critical speed to achieve a powerful cataracting motion.

- If your primary focus is fine grinding of a brittle material where impact fracture is undesirable: Consider a lower speed (around 50-60% of critical) where gentle abrasion is the more dominant mechanism.

- If your primary focus is understanding process limits: Approaching or exceeding the critical speed demonstrates the point at which centrifugal force overcomes gravity and all grinding action stops.

Ultimately, controlling rotational speed is how you control the balance between impact and abrasion—the very heart of the ball milling process.

Summary Table:

| Speed Regime | Grinding Mechanism | Effect on Size Reduction |

|---|---|---|

| Low Speed (Tumbling) | Abrasion (rubbing/shearing) | Slow, inefficient grinding |

| Optimal Speed (Cataracting) | Impact + Abrasion combination | Fastest, most efficient size reduction |

| High Speed (Centrifuging) | No grinding (balls pinned to wall) | Grinding stops completely |

Maximize your ball mill's performance and achieve precise particle size control. KINTEK specializes in laboratory equipment and consumables, providing solutions for all your grinding needs. Our experts can help you select the right equipment and optimize operational parameters like rotational speed for your specific materials. Contact us today to discuss how we can enhance your lab's efficiency and productivity!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Hybrid High Energy Vibratory Ball Mill for Lab Use

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory High Throughput Tissue Grinding Mill Grinder

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What are the requirements for ball milling jars in LiMOCl4 synthesis? Ensure Safety and Purity in High-Pressure Reactions

- What is the primary function of a planetary ball mill? Mastering SiC/Al Composite Mixing for Homogeneity

- What is the function of a planetary ball mill in the synthesis of (Cu–10Zn)-Al2O3 nanocomposites? High-Energy Alloying

- What are the unique energy transfer characteristics of PBM? Master Complex Heterocyclic Synthesis

- What is the primary function of a planetary ball mill in ODS steel prep? Achieving Nanoscale Mechanical Alloying