The fundamental problem with plastic waste is that it has no natural end product. Unlike organic materials that decompose, plastic is non-biodegradable, meaning it does not break down into harmless substances. Instead, it persists in the environment for hundreds or even thousands of years, simply fragmenting into smaller pieces or accumulating in landfills and oceans.

The true "end product" of plastic waste is long-term environmental contamination. Its defining quality—durability—ensures it accumulates in our ecosystems for centuries, posing a significant threat to land, water, and wildlife.

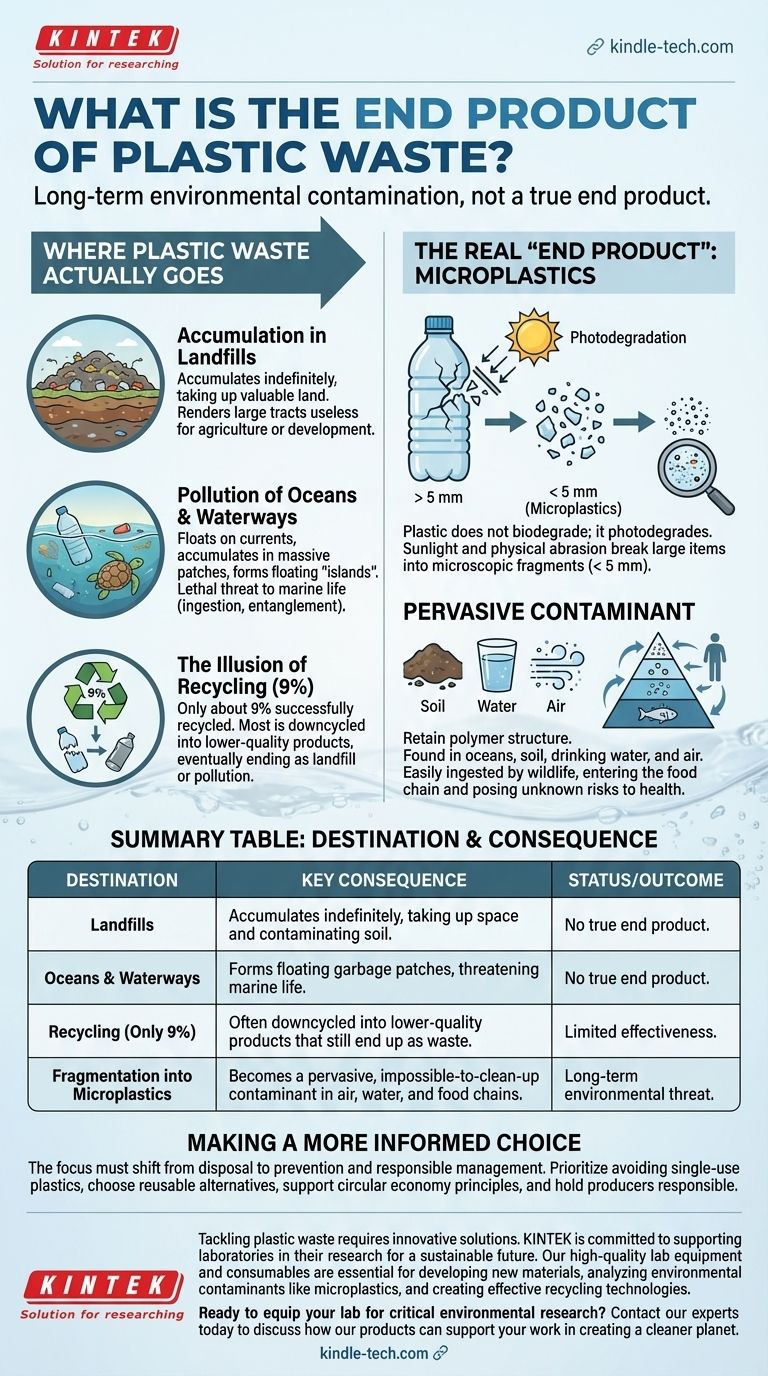

Where Plastic Waste Actually Goes

When we "throw away" plastic, it doesn't truly disappear. It is simply moved to one of several destinations, each with its own severe environmental consequences.

Accumulation in Landfills

The vast majority of plastic waste ends up in landfills. Because it is non-biodegradable, it takes up valuable space indefinitely.

Over time, this accumulation can render large tracts of land useless for other purposes like agriculture or development.

Pollution of Oceans and Waterways

A significant amount of plastic waste finds its way into rivers and, ultimately, the ocean. Being less dense than water, much of it floats and travels on currents.

This plastic accumulates in massive patches, sometimes forming floating "islands." This poses a direct and lethal threat to marine life through ingestion and entanglement. The current trajectory suggests our oceans could contain more plastic than fish by weight by 2050.

The Illusion of Recycling

While recycling is a crucial part of the solution, it is not a final destination for most plastics. Currently, only about 9% of all plastic waste is successfully recycled.

Even when recycled, most plastics are downcycled into lower-quality products that cannot be recycled again, eventually ending their lifecycle in a landfill or as pollution.

The Real "End Product": Microplastics

The most insidious outcome for plastic waste is its fragmentation into smaller and smaller particles known as microplastics.

What Fragmentation Means

Plastic does not biodegrade; it photodegrades. Sunlight and physical abrasion break large plastic items into microscopic fragments, some less than 5 millimeters in size.

These particles retain their polymer structure. They are still plastic, just in a form that is impossible to clean up and easy to disperse.

A Pervasive Contaminant

Microplastics have become a pervasive global contaminant. They are found in our oceans, soil, drinking water, and even the air we breathe.

Because of their small size, they are easily ingested by wildlife, entering the food chain at every level and posing a yet-unquantified risk to ecosystem and human health.

Making a More Informed Choice

Understanding that plastic has no true end-of-life cycle is the first step toward addressing the problem. The focus must shift from disposal to prevention and responsible management.

- If your primary focus is reducing your personal impact: Prioritize avoiding single-use plastics and choose reusable alternatives whenever possible.

- If your primary focus is systemic change: Support businesses and policies that champion circular economy principles, improve recycling infrastructure, and hold producers responsible for their packaging.

Ultimately, we must treat plastic not as a disposable convenience but as a durable material that requires a permanent management strategy.

Summary Table:

| Destination of Plastic Waste | Key Consequence |

|---|---|

| Landfills | Accumulates indefinitely, taking up space and contaminating soil. |

| Oceans & Waterways | Forms floating garbage patches, threatening marine life. |

| Recycling (Only 9%) | Often downcycled into lower-quality products that still end up as waste. |

| Fragmentation into Microplastics | Becomes a pervasive, impossible-to-clean-up contaminant in air, water, and food chains. |

Tackling plastic waste requires innovative solutions. KINTEK is committed to supporting laboratories in their research for a sustainable future.

Our high-quality lab equipment and consumables are essential for researchers developing new materials, analyzing environmental contaminants like microplastics, and creating effective recycling technologies. Whether you need reliable filtration systems, analytical instruments, or durable labware for your environmental science projects, KINTEK provides the tools for discovery.

Ready to equip your lab for critical environmental research? Contact our experts today to discuss how our products can support your work in creating a cleaner planet.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Polyethylene Separator for Lithium Battery

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

People Also Ask

- What is the temperature at the bottom of the blast furnace? Unlocking the Heart of Iron Production

- How does microwave pretreatment improve the leaching efficiency of rare earth elements? Boost Extraction with KINTEK

- What is the effect of sintering on microstructures? Achieve Precise Control of Material Properties

- At what temperature do terpenes evaporate? Unlock the Full Flavor and Effects of Your Cannabis

- How is a crucible used in the crucible? Unpacking Arthur Miller's Powerful Metaphor

- What is the financial cost of using biomass? Unpacking the $70-$160/MWh Price Range

- How does a laboratory drying oven contribute to TiO2 synthesis? Unlock Advanced Material Stability & Chemical Bonding

- What are the defects in the heat treatment process? Prevent Cracking, Warping, and Soft Spots