The feedstock for biochar is any organic, carbon-rich material, often referred to as biomass. This includes a vast range of materials such as wood chips, agricultural crop residues like corn stover or rice husks, forestry waste, animal manures, and even biosolids. The specific material used is the single most important factor determining the final properties of the biochar.

While almost any biomass can be used to create biochar, the critical insight is that the choice of feedstock directly controls the resulting biochar's chemical and physical properties. This dictates its suitability for specific applications, from carbon sequestration to soil amendment.

The Foundation: What Qualifies as a Feedstock?

The core principle behind biochar production, a process called pyrolysis, is heating organic material in a low-oxygen environment. This means the primary requirement for a feedstock is that it must be biomass—material derived from living or recently living organisms.

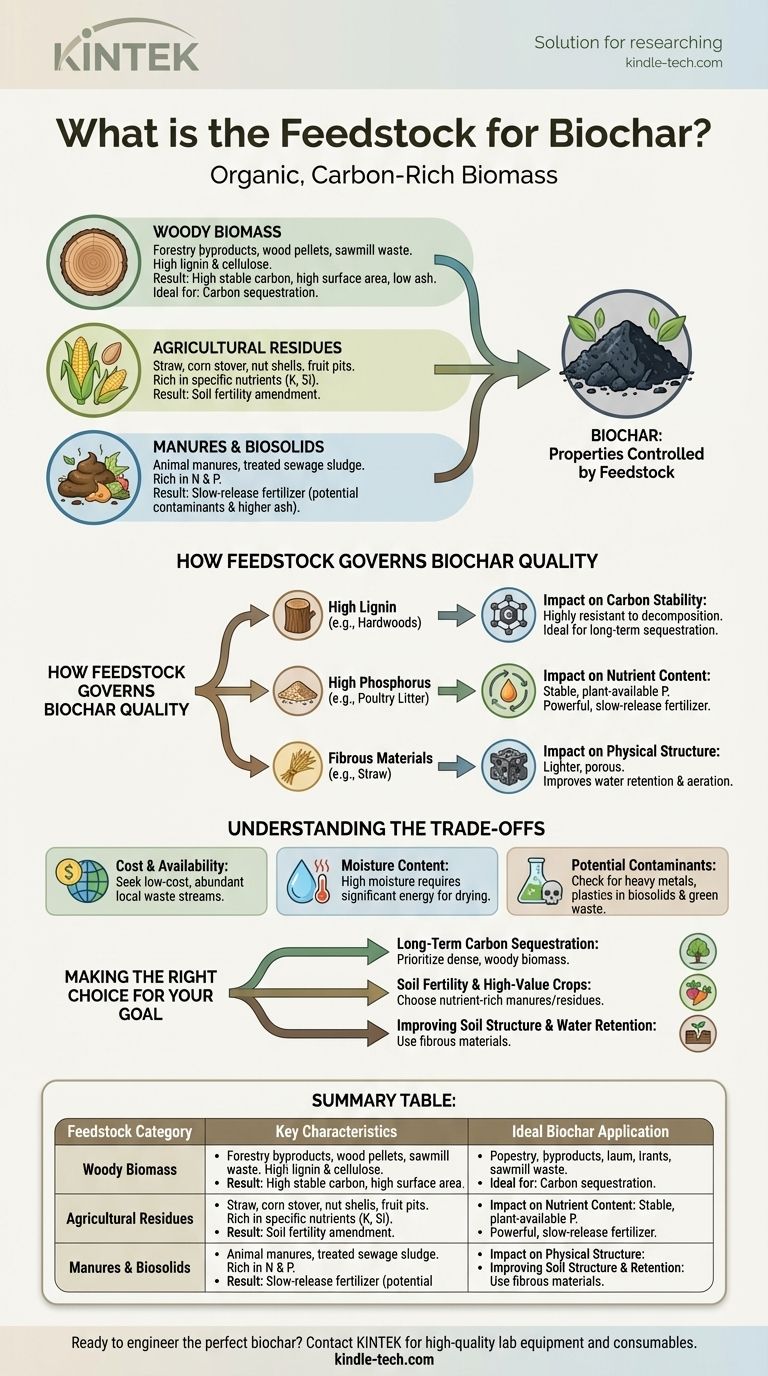

Key Feedstock Categories

Feedstocks are generally grouped by their origin, with each category producing biochar with distinct characteristics.

- Woody Biomass: This includes forestry byproducts, wood pellets, and waste from sawmills. These feedstocks are high in lignin and cellulose, which results in a biochar that is typically high in stable carbon, has a high surface area, and is low in ash.

- Agricultural Residues: Materials like straw, corn stover, nut shells, and fruit pits fall into this category. The resulting biochar often contains higher levels of specific plant nutrients, such as potassium (K) or silica (Si), making it valuable for replenishing soils.

- Manures and Biosolids: Animal manures and treated sewage sludge are rich in nutrients like nitrogen (N) and phosphorus (P). Biochar from these sources can act as a slow-release fertilizer but may also have a higher ash content and require careful testing for potential contaminants.

How Feedstock Governs Biochar Quality

The starting material is not just a fuel for the process; it's the blueprint for the final product. The feedstock's composition directly influences the biochar's performance, especially when used as a soil amendment.

Impact on Carbon Stability

Feedstocks with high lignin content, such as hardwoods, produce biochar with a more stable carbon structure. This makes it highly resistant to decomposition, which is ideal for long-term carbon sequestration in soil.

Impact on Nutrient Content

Feedstocks like poultry litter or bone meal are naturally high in phosphorus. When converted to biochar, this phosphorus becomes a stable, plant-available nutrient source, creating a powerful, slow-release fertilizer.

Impact on Physical Structure

The physical nature of the feedstock matters. For example, fibrous materials like straw can produce a lighter, more porous biochar, which is excellent for improving water retention and aeration in dense clay soils.

Interaction with Production Conditions

The choice of feedstock also dictates the ideal production process. A dense, wet feedstock requires more energy and a longer residence time at a high temperature to convert fully compared to a light, dry feedstock like grass clippings.

Understanding the Trade-offs

Selecting a feedstock is a balancing act between ideal characteristics and practical realities. There is no single "best" material; the right choice depends on the intended application and local availability.

Cost and Availability

The most significant factor is often accessibility. The ideal feedstock is a low-cost, abundant local waste stream. Using a material that would otherwise end up in a landfill transforms a disposal cost into a valuable resource.

Moisture Content

High moisture content is a major drawback. Significant energy must be expended to dry the feedstock before it can undergo pyrolysis, which dramatically reduces the overall energy efficiency of the process.

Potential Contaminants

It is critical to know the history of your feedstock. Biosolids, for instance, can contain heavy metals, while municipal green waste might be contaminated with plastics. These contaminants can render the final biochar unsuitable and even harmful for agricultural use.

Making the Right Choice for Your Goal

To select the appropriate feedstock, you must first define your primary objective for the biochar.

- If your primary focus is long-term carbon sequestration: Prioritize dense, woody biomass like hardwoods to create the most stable, carbon-rich biochar.

- If your primary focus is soil fertility for high-value crops: Choose nutrient-rich feedstocks like specific manures or agricultural residues to deliver targeted nutrients.

- If your primary focus is improving soil structure and water retention: Use fibrous materials like straw or corn stover that produce a porous, low-density biochar.

Ultimately, selecting the right feedstock transforms a simple organic material into a precisely engineered tool for agricultural and environmental benefit.

Summary Table:

| Feedstock Category | Key Characteristics | Ideal Biochar Application |

|---|---|---|

| Woody Biomass | High lignin, stable carbon, low ash | Long-term carbon sequestration, soil structure |

| Agricultural Residues | High in specific nutrients (e.g., K, Si) | Soil fertility amendment, nutrient replenishment |

| Manures & Biosolids | High in nutrients (N, P), potential for higher ash | Slow-release fertilizer, requires contaminant testing |

Ready to engineer the perfect biochar for your project? The right feedstock is the first step to success. KINTEK specializes in providing the high-quality lab equipment and consumables you need for precise pyrolysis and analysis. Whether you're researching carbon sequestration or developing a soil amendment, our solutions help you achieve consistent, reliable results. Contact our experts today to discuss how we can support your biochar production and research goals.

Visual Guide

Related Products

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Graphite Vacuum Continuous Graphitization Furnace

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

People Also Ask

- What is the importance of leakage in a vacuum system? Prevent Contamination and Process Failure

- What instrument is used to measure vacuum? Selecting the Right Gauge for Your Pressure Range

- What is the function of a laboratory vacuum system in preparing COF precursors? Ensure Purity & Prevent Oxidation

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- How is vacuum pressure measured? A Guide to Accurate Gauges and Techniques