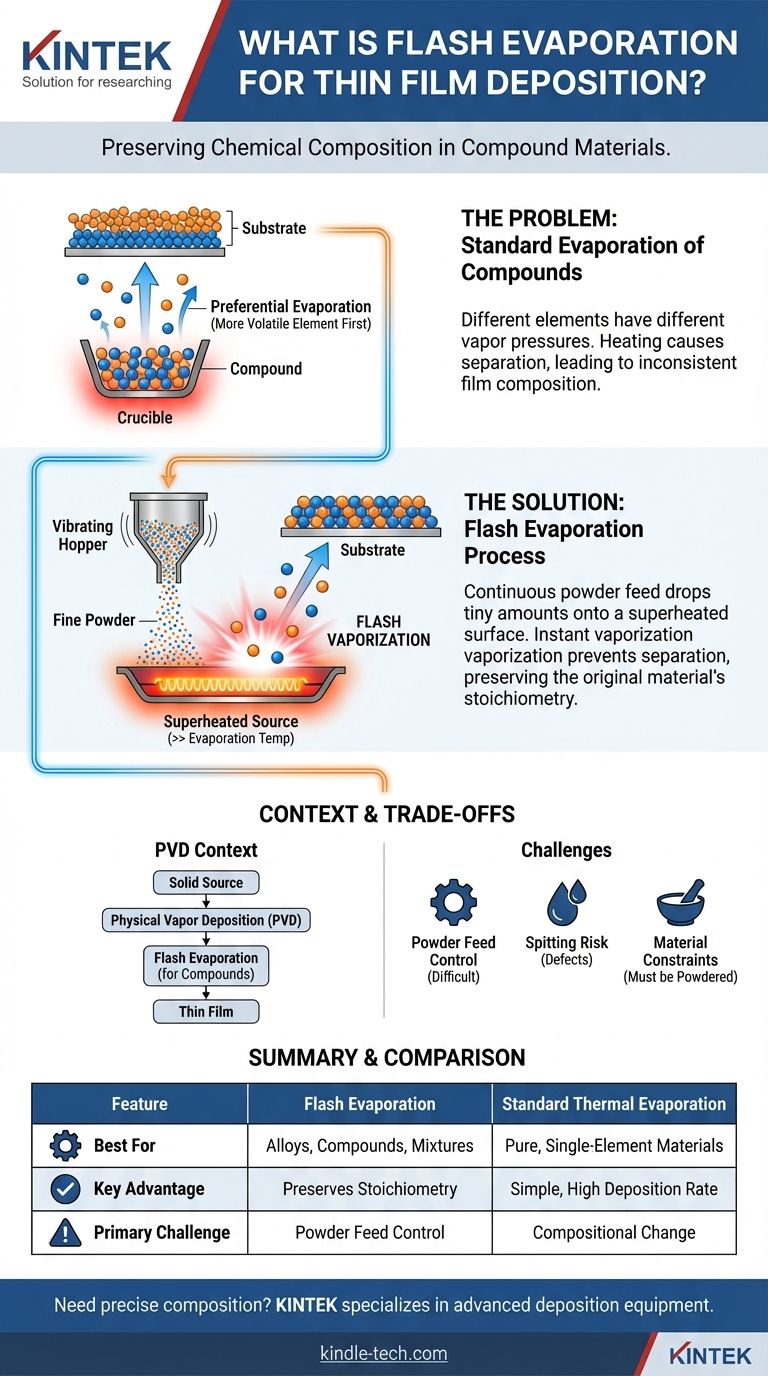

Flash evaporation is a specialized thermal deposition technique used to create thin films from materials that are alloys, compounds, or mixtures. It works by continuously dropping a fine powder of the source material onto a surface heated well above the evaporation temperature of all its constituent elements. This "flash" of heat vaporizes the powder so quickly that it prevents the material from separating, ensuring the resulting vapor—and the final film—has the same chemical composition as the original source material.

The central challenge with standard evaporation is that different elements in a compound or alloy vaporize at different rates, altering the final film's composition. Flash evaporation solves this by vaporizing tiny, uniform quantities of material almost instantaneously, forcing all components to transfer to the vapor phase together and preserving the original material's stoichiometry.

The Fundamental Challenge: Evaporating Compound Materials

To understand the value of flash evaporation, we must first grasp the problem it was designed to solve. The process is a direct response to a fundamental issue in the physics of standard thermal evaporation.

The Problem of Different Vapor Pressures

Most materials are not pure elements. They are compounds or alloys made of multiple elements, each with its own unique boiling point and vapor pressure.

When you heat a compound material in a standard thermal evaporator, the element with the highest vapor pressure (the lowest boiling point) begins to evaporate first and at a faster rate.

The Result: Inconsistent Film Composition

This preferential evaporation leads to a vapor stream that is initially rich in the more volatile element. As the process continues, the source material becomes depleted of that element.

The consequence is a thin film whose chemical composition is inconsistent and does not match the original source material. The bottom layer of the film will be different from the top layer.

How Flash Evaporation Solves the Problem

Flash evaporation is an ingenious solution that bypasses the issue of differential vapor pressures by changing the dynamics of the heating process.

The Continuous Powder Feed

Instead of placing a large chunk of material in a crucible to be heated slowly, flash evaporation uses a mechanism to continuously vibrate and dispense a fine, consistent powder of the source material.

The Superheated Evaporation Source

This powder is dropped in small, controlled quantities onto an extremely hot filament or "boat," which is maintained at a temperature significantly higher than the evaporation point of any component in the powder.

Preserving Stoichiometry

When a tiny grain of powder hits this superheated surface, it is vaporized almost instantly—in a "flash." This process is so rapid that there is no time for the elements to separate. The entire particle vaporizes as a whole, preserving the material's original composition, or stoichiometry, in the vapor cloud and, ultimately, in the deposited thin film.

Where Flash Evaporation Fits in the Deposition Landscape

Thin film deposition methods are broadly categorized, and understanding flash evaporation's place provides critical context.

A Variant of Physical Vapor Deposition (PVD)

Flash evaporation is a type of Physical Vapor Deposition (PVD). Like other PVD methods, it involves physically turning a solid material into a vapor in a vacuum, which then travels and condenses on a substrate to form a film. It does not rely on chemical reactions like Chemical Vapor Deposition (CVD).

Comparison to Standard Thermal Evaporation

Standard thermal evaporation and e-beam evaporation are excellent for depositing pure materials like a single metal. However, as noted, they fail when the source is a compound. Flash evaporation is the necessary modification to handle these more complex source materials.

Understanding the Trade-offs and Limitations

While effective, flash evaporation is not without its challenges. It is a specialized technique chosen when its unique benefits outweigh its operational complexities.

Control and Repeatability

Achieving a perfectly consistent and clog-free powder feed is mechanically challenging. Variations in the powder drop rate can lead to fluctuations in the deposition rate and film uniformity, making process control more difficult than with standard evaporation.

Potential for Spitting

If the powder particles are too large or the drop rate is too high, the material can "spit" from the hot source rather than evaporating cleanly. This can lead to defects and rough surface morphology in the final film.

Source and Material Constraints

The technique requires that the source material can be successfully ground into a fine, free-flowing powder. Additionally, the superheated source can degrade over time or potentially react with the source material, which must be considered.

Making the Right Choice for Your Goal

Selecting a deposition method requires a clear understanding of your source material and the desired properties of your final film.

- If your primary focus is depositing a pure, single-element film (e.g., gold or aluminum): Standard thermal or e-beam evaporation is far more straightforward, controllable, and reliable.

- If your primary focus is creating a film from a specific alloy or multi-element compound (e.g., a semiconductor like Cadmium Telluride): Flash evaporation is a powerful candidate to ensure the film's chemical composition precisely matches the source material.

- If your primary focus is creating a high-purity, dense film via surface chemical reactions: Chemical Vapor Deposition (CVD) represents a completely different category of methods better suited for that objective.

Ultimately, the choice of flash evaporation is driven by the fundamental need to preserve the chemical integrity of a complex material during its journey from solid source to thin film.

Summary Table:

| Feature | Flash Evaporation | Standard Thermal Evaporation |

|---|---|---|

| Best For | Alloys, Compounds, Mixtures | Pure, Single-Element Materials |

| Key Advantage | Preserves Source Material Stoichiometry | Simple, High Deposition Rate |

| Primary Challenge | Controlling Powder Feed & Preventing Spitting | Compositional Change in Compounds |

| Process | Instantaneous vaporization of fine powder | Slow heating of a solid source |

Need to deposit thin films with precise chemical composition? KINTEK specializes in lab equipment for advanced deposition techniques like flash evaporation. Whether you're working with semiconductor alloys or complex compounds, our solutions ensure your film's stoichiometry matches your source material perfectly. Contact our experts today to discuss how we can enhance your laboratory's thin film capabilities!

Visual Guide

Related Products

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is e beam evaporation synthesis of nano films? A Guide to High-Purity Thin Films

- What is the deposition of thin films? A Guide to Coating Technology for Modern Devices

- What is thermal evaporation of thin film? A Guide to High-Purity PVD Coating

- What is the source of electron beam evaporation? The Electron Gun Explained for High-Purity Thin Films

- What material is evaporation by resistive heating used for? Ideal for Metals Like Gold & Aluminum

- What is thermal evaporation under a vacuum? A Guide to High-Purity Thin Film Deposition

- What is the voltage of e-beam evaporation? Achieve Precise Thin-Film Deposition

- Is electron beam assisted evaporation used for metals? The Key to High-Purity, High-Melting-Point Metal Films