At its core, a crucible is a ceramic or metal container used to hold substances that need to be heated to extremely high temperatures. Its primary function is to withstand intense heat without melting, breaking, or reacting with the material inside, allowing for processes like melting metals or performing high-temperature chemical analyses.

A crucible's true purpose isn't just to hold a sample, but to serve as a chemically inert and thermally stable environment. This ensures that the only changes occurring during heating are within the sample itself, providing pure and reliable results.

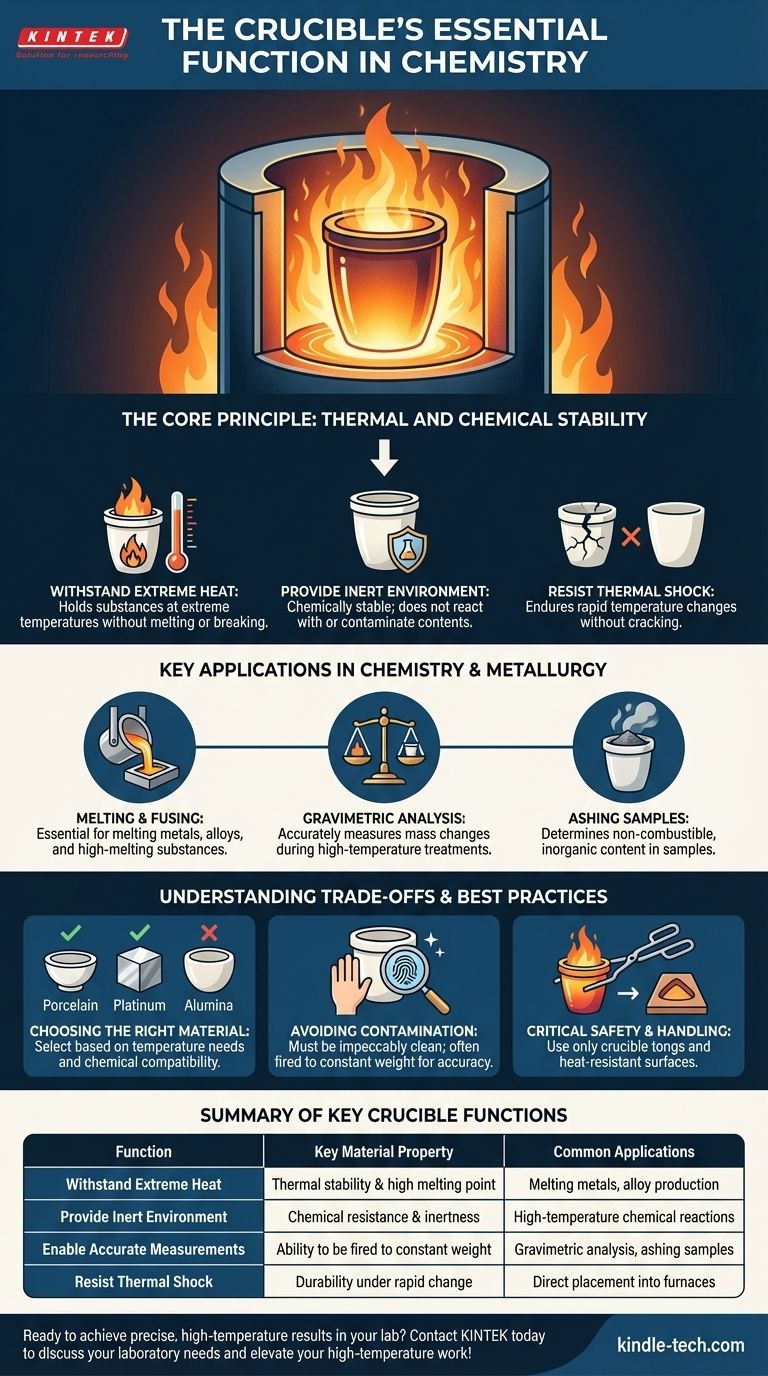

The Core Principle: Thermal and Chemical Stability

A crucible's function is entirely dependent on the material it's made from. It is specifically engineered to be a passive container under extreme conditions where a glass beaker or flask would fail.

What Defines a Crucible?

A crucible is typically a small, cup-shaped container. Unlike standard laboratory glassware, it is opaque and has thick walls designed for thermal durability rather than transparency.

Why Material is Everything

Crucibles are made from refractory materials—substances that are physically and chemically stable at high temperatures. Common materials include porcelain, alumina, and inert metals like platinum or nickel.

The choice of material ensures the crucible itself does not become a variable in the experiment. It won't melt, and it won't react with or contaminate the chemicals it holds.

Resisting Thermal Shock

These containers are designed to withstand thermal shock, which is the stress a material undergoes when it experiences a rapid change in temperature. This allows a crucible to be placed directly into a hot furnace or over a Bunsen burner and later cooled without cracking.

Key Applications in Chemistry and Metallurgy

While simple in form, the crucible is essential for several critical scientific and industrial processes. The reference to a crucible furnace highlights its central role in melting.

Melting Metals and Fusing Solids

As noted, one of the most common uses is melting substances with high melting points, such as metals. Inside a furnace, the crucible transfers heat to the metal until it becomes molten, at which point it can be poured into a mold to create an alloy or cast part.

Gravimetric Analysis

In analytical chemistry, crucibles are fundamental to gravimetric analysis. This technique involves accurately determining the mass of a substance.

A sample is placed in a pre-weighed crucible and heated. This process might be used to drive off water from a hydrated salt or to burn away combustible materials, leaving only a stable residue. The final mass is then measured to calculate the composition of the original sample.

Ashing Samples

Ashing is a specific type of gravimetric analysis used to determine the amount of non-combustible, inorganic content (the "ash") in a sample. The sample is placed in a crucible and heated in a furnace at a high temperature until all organic matter has burned away.

Understanding the Trade-offs and Best Practices

Using a crucible effectively requires understanding its limitations and proper handling procedures to ensure safety and accuracy.

Choosing the Right Material

Porcelain crucibles are excellent for general-purpose heating and are relatively inexpensive. However, for extremely high temperatures or when working with highly corrosive substances, a more inert and robust material like platinum may be necessary.

The Risk of Contamination

Because many applications rely on precise mass measurements, a crucible must be impeccably clean. Any residue or even fingerprints can add measurable mass and skew results. They are often "fired to constant weight"—heated and cooled repeatedly until their mass no longer changes—before a sample is added.

Critical Safety and Handling

Crucibles become dangerously hot and look identical to cool ones. They must only be handled with a pair of crucible tongs. When being heated, a crucible is typically placed on a clay "pipe-stem" triangle, and it should only be set down on a heat-resistant surface to cool.

Making the Right Choice for Your Goal

Your specific objective dictates how you should approach using a crucible.

- If your primary focus is quantitative analysis: Ensure the crucible is heated to a constant weight before adding your sample to guarantee measurement accuracy.

- If your primary focus is melting metals: Select a crucible material with a melting point significantly higher than your target metal and which will not form alloys with it.

- If your primary focus is observing a high-temperature reaction: A standard porcelain crucible is often sufficient, but always confirm it won't react with any of your chemical reagents.

Ultimately, the crucible is the simple yet indispensable tool that makes high-temperature chemistry possible.

Summary Table:

| Function | Key Material Property | Common Applications |

|---|---|---|

| Withstand extreme heat | Thermal stability & high melting point | Melting metals, alloy production |

| Provide a chemically inert environment | Chemical resistance & inertness | High-temperature chemical reactions |

| Enable accurate mass measurements | Ability to be fired to constant weight | Gravimetric analysis, ashing samples |

| Resist thermal shock | Durability under rapid temperature change | Direct placement into furnaces |

Ready to achieve precise, high-temperature results in your lab?

The right crucible is essential for reliable melting, analysis, and ashing. KINTEK specializes in high-quality lab equipment and consumables, including a full range of crucibles made from materials like porcelain, alumina, and platinum, designed for thermal stability and chemical inertness.

Let our experts help you select the perfect crucible for your specific application—ensuring accuracy, safety, and purity in your processes.

Contact KINTEK today to discuss your laboratory needs and elevate your high-temperature work!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- Why is the use of high-purity alumina crucibles necessary for NMC powders? Ensure Purity in Cathode Synthesis

- What role does an Alumina Crucible play in the high-temperature solid-state synthesis of Na3OBr? Ensure Sample Purity

- What is the function of alumina crucibles in Na3V2(PO4)2F3 synthesis? Ensure Purity in NVPF Production

- Why are high-purity alumina crucibles used for LATP? Preserve Purity and Conductivity in Sintering

- What are the functional advantages of using high-purity alumina crucibles? Achieve Precise Oxidation Data