At its core, a sieve shaker machine automates the process of separating a material sample by particle size. It uses a controlled vibratory or shaking motion to agitate a stack of sieves with progressively smaller mesh openings. This allows a laboratory or quality control professional to quickly and accurately determine the particle size distribution within that material.

The primary function of a sieve shaker is to replace inconsistent, labor-intensive manual sieving with a highly repeatable and efficient automated process. This generates the reliable particle size data essential for quality control, research, and production across numerous industries.

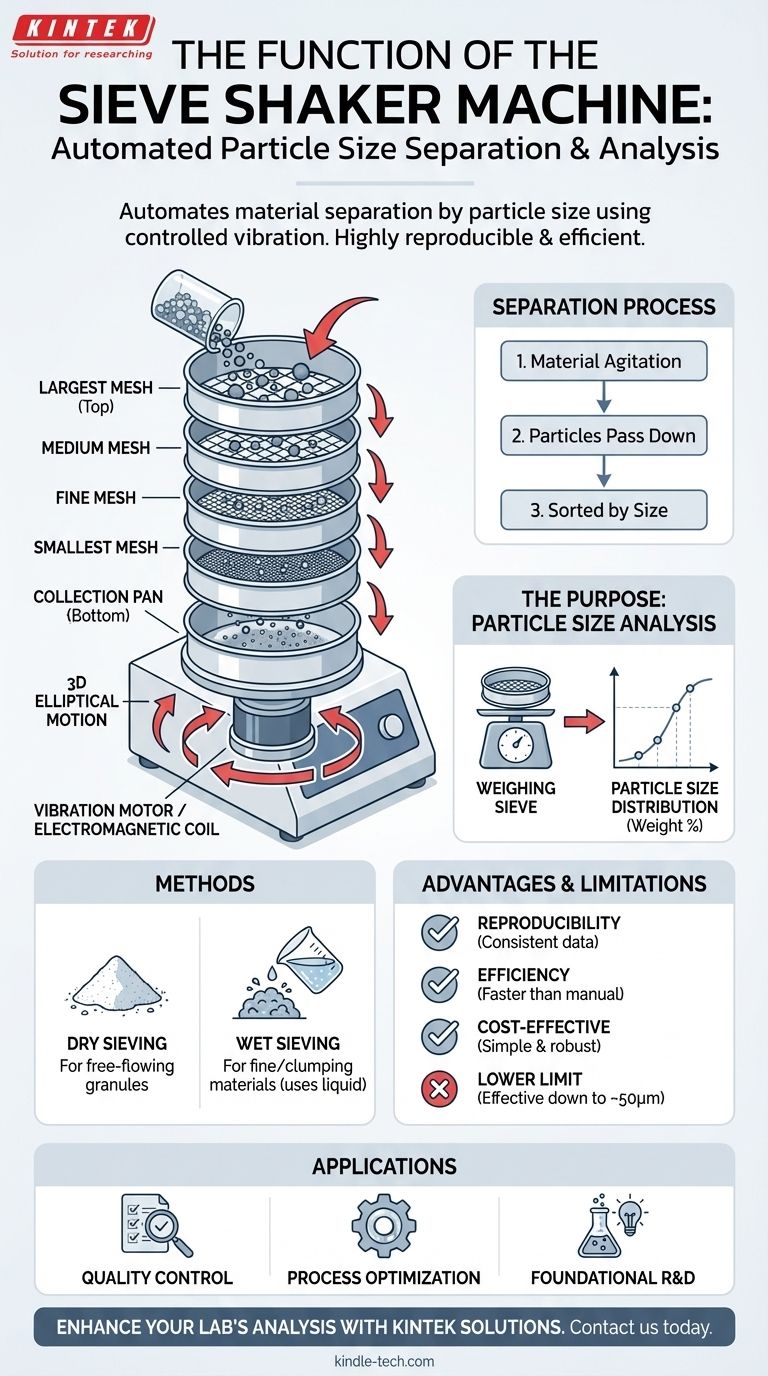

How a Sieve Shaker Achieves Precise Separation

A sieve shaker does not simply shake a sample randomly. It employs a precise mechanical action to ensure particles have the maximum opportunity to pass through the appropriate sieve apertures, resulting in an accurate physical separation.

The Principle of Agitation

The heart of the machine is its drive system, which is typically either a vibration motor or an electromagnetic coil. This system imparts a specific motion to the platform where the sieves are secured.

Some shakers use a simple vibratory action, while more advanced models, like electromagnetic shakers, create a three-dimensional elliptical motion. This 3D movement is highly effective as it both lifts the material and rotates it, preventing particles from clogging the mesh and ensuring a more complete separation.

The Role of the Sieve Stack

The process relies on a stack of test sieves. These are precision-made pans with a wire mesh filter of a specific, certified aperture size at the bottom.

Sieves are stacked in descending order, with the sieve having the largest openings at the top and the one with the smallest openings at the bottom. A solid collection pan is placed at the very bottom of the stack to catch the finest particles.

The Separation Process in Action

When a material sample is placed in the top sieve and the machine is activated, the agitation begins. Particles smaller than the top sieve's mesh fall through to the sieve below.

This process continues down the stack. A particle's journey ends when it reaches a sieve with mesh openings too small for it to pass through. After the set time, the machine stops, and the material is left sorted on various levels of the sieve stack.

The Purpose Beyond Shaking: Particle Size Analysis

The physical separation is just the first step. The true function of the sieve shaker is to enable quantitative particle size analysis.

From Sorted Material to Usable Data

After the shaking cycle is complete, the material retained on each individual sieve is weighed. This data is then used to calculate the particle size distribution of the original sample, typically expressed as a weight percentage.

This tells you precisely what percentage of your material falls within specific size ranges. Modern shakers often connect to software that automates these calculations and report generation.

Wet vs. Dry Sieving

Sieve shakers can handle both dry and wet samples. Dry sieving is the most common method for powders and granules that flow freely.

Wet sieving is used for materials that tend to clump together or are very fine. A liquid (usually water) is used to disperse the particles and help them pass through the apertures without agglomerating.

Understanding the Advantages and Trade-offs

While powerful, a sieve shaker is one of several tools for particle analysis. Understanding its specific strengths and weaknesses is key to using it effectively.

Key Advantage: Reproducibility and Efficiency

Compared to manual hand sieving, an automated shaker offers vastly superior reproducibility. The machine performs the exact same motion for the exact same duration every time, eliminating human variability and producing accurate, defensible data. It is also significantly faster.

Key Advantage: Simplicity and Cost-Effectiveness

Sieve shakers are considered a straightforward and relatively low-cost method for particle size analysis. They are easy to operate, robust, and require minimal installation space, making them a foundational instrument in many labs.

A Critical Limitation: The Lower Size Boundary

Sieve analysis is most effective for coarse materials down to finer powders, typically around 50 micrometers (µm). For particles smaller than this (sub-sieve range), other methods like laser diffraction or dynamic light scattering become necessary as physical separation becomes impractical.

Making the Right Choice for Your Goal

The data from a sieve shaker is a powerful tool for process control and material characterization. How you apply it depends on your specific objective.

- If your primary focus is rapid quality control: A sieve shaker provides a fast and reliable way to verify that an incoming raw material or finished product meets particle size specifications.

- If your primary focus is process optimization: Use the distribution data to understand how adjustments in your manufacturing process (like grinding time or temperature) affect the final material characteristics.

- If your primary focus is foundational R&D: The sieve shaker is an excellent starting point for characterizing new granular materials and establishing baseline properties for development.

By applying controlled motion to a simple stack of sieves, the sieve shaker transforms a basic physical separation into critical, actionable data.

Summary Table:

| Function | Key Benefit | Typical Use Case |

|---|---|---|

| Automated Sieving | Replaces manual labor for high reproducibility and efficiency. | Quality control checks on raw materials and finished products. |

| Particle Separation | Physically sorts material by size using a stack of test sieves. | Determining the particle size distribution of powders and granules. |

| Data Generation | Enables calculation of weight percentages for specific size ranges. | Process optimization and research & development (R&D). |

| Wet & Dry Analysis | Handles a wide range of materials, including those that clump. | Analyzing fine powders or cohesive materials with wet sieving. |

Ready to Enhance Your Lab's Particle Analysis?

Accurate and reproducible particle size data is fundamental to quality control and R&D. KINTEK specializes in providing robust and efficient sieve shakers and the full range of lab equipment and consumables needed to support your laboratory's precise analytical needs.

Let us help you achieve reliable results. Our experts can guide you to the ideal solution for your specific materials and application requirements.

Contact KINTEK today to discuss how our sieve shakers and support can streamline your particle size analysis workflow.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- What are the principles of a sieve shaker? Achieve Accurate Particle Size Analysis

- What key role does sieving equipment play for SiC/ZTA ceramic powder? Ensure Uniform Density & Defect-Free Sintering

- What is the frequency of a sieve shaker? The Key to Accurate Particle Size Analysis

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What role does a laboratory shaker play in the extraction of plant compounds for green synthesis? Maximize Your Yield

- What is a shaking machine for wet sieving? Achieve Accurate Particle Size Analysis for Fine Powders

- What is the function of crushing and sieving systems in the mechanical pretreatment of algal biomass? Boost Methane Yield

- What factors influence particle size analysis by sieving? Master Key Variables for Accurate Results