In simple terms, a CVD diamond is a 10 on the Mohs scale of hardness, the highest possible value, which is identical to that of a natural diamond. For more precise engineering applications, its hardness is frequently measured at around 8,500 kgf/mm², confirming it as one of the hardest materials known.

The critical insight is that while CVD diamond matches the peak hardness of natural diamond, its exact properties are not fixed. The manufacturing process allows for precise control, meaning its hardness, smoothness, and other characteristics can be intentionally tailored for specific, high-performance applications.

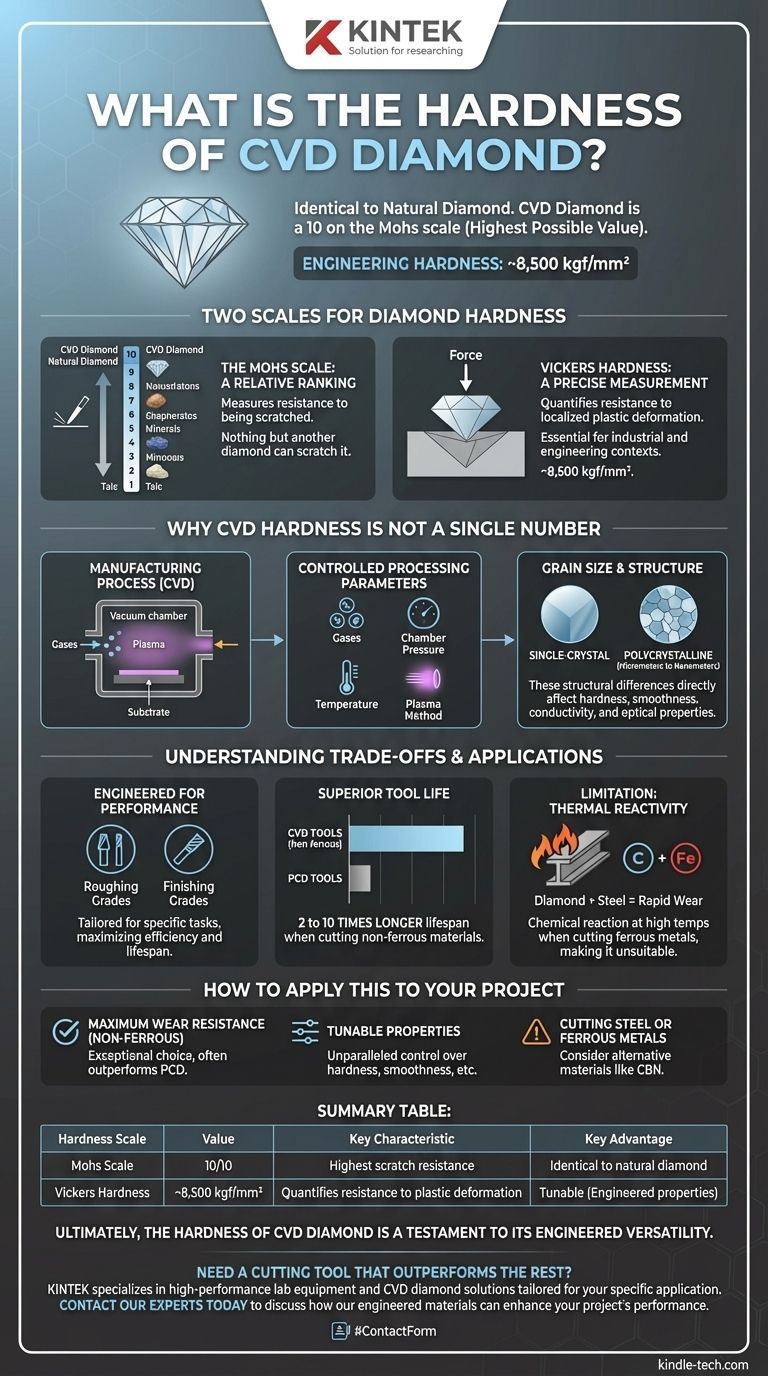

Two Scales for Diamond Hardness

To fully understand the data, it's important to distinguish between the two common methods of measuring hardness. Each tells a different part of the story.

The Mohs Scale: A Relative Ranking

The Mohs scale is a simple, relative test that measures a material's resistance to being scratched by another. It runs from 1 (Talc) to 10 (Diamond).

Because a CVD diamond has the same carbon crystal structure as a natural one, it sits at the top of this scale. Nothing but another diamond can scratch it.

Vickers Hardness: A Precise Measurement

The value of 8,500 kgf/mm² comes from a more scientific test, likely the Vickers hardness test. This involves pressing a diamond indenter into the material with a specific force.

This measurement quantifies the material's resistance to localized plastic deformation. It is far more useful for industrial and engineering contexts where precise performance data is required.

Why CVD Hardness Is Not a Single Number

The most significant advantage of the CVD process is the ability to engineer the diamond's final properties. The hardness isn't a universal constant but a variable that can be optimized.

The Role of the Manufacturing Process

The Chemical Vapor Deposition (CVD) process involves growing a diamond layer by layer from carbon-rich gas in a vacuum chamber.

By meticulously controlling the conditions within that chamber, manufacturers can influence the final crystal structure of the diamond.

Controlled Processing Parameters

Key factors like the specific gases used, chamber pressure, temperature, and plasma generation method all impact the final product.

Adjusting these parameters allows for the creation of different diamond materials with slightly different characteristics.

Grain Size and Structure

This control makes it possible to produce single-crystal or polycrystalline diamonds with grain sizes ranging from micrometers down to nanometers.

These structural differences directly affect the diamond's final hardness, smoothness, conductivity, and even its optical properties.

Understanding the Trade-offs and Applications

This ability to tailor hardness makes CVD diamond an exceptionally versatile material for industrial tools, but it's not without its specific limitations.

Engineered for Performance

Because properties can be controlled, manufacturers can create distinct grades of CVD diamond, such as "Roughing" and "Finishing" types for cutting tools.

This ensures the tool's characteristics are perfectly matched to the task, maximizing efficiency and lifespan.

Superior Tool Life

In its primary applications, the performance of CVD diamond is exceptional. When used for cutting non-ferrous materials, CVD tools can have a lifespan 2 to 10 times longer than Polycrystalline Diamond (PCD) tools.

The Limitation of Thermal Reactivity

The primary trade-off is chemical, not physical. At the high temperatures generated when cutting steel and other ferrous metals, the carbon in the diamond can react with the iron.

This chemical reaction, not a failure of hardness, causes the diamond tool to wear out quickly, making it unsuitable for these specific applications.

How to Apply This to Your Project

Choosing the right diamond material depends entirely on your specific engineering or design goal.

- If your primary focus is maximum wear resistance for non-ferrous materials: CVD diamond is an exceptional choice, often outperforming traditional PCD tools due to its engineered purity and structure.

- If you need a material with tunable properties: The CVD process offers unparalleled control over hardness, smoothness, and other characteristics to meet highly specific demands.

- If you are cutting steel or other ferrous metals: You must consider the high-temperature chemical reactivity of diamond and explore alternative materials like CBN (Cubic Boron Nitride).

Ultimately, the hardness of CVD diamond is not just a static property but a testament to its engineered versatility.

Summary Table:

| Hardness Scale | Value | Key Characteristic |

|---|---|---|

| Mohs Scale | 10/10 | Highest scratch resistance, identical to natural diamond |

| Vickers Hardness | ~8,500 kgf/mm² | Quantifies resistance to plastic deformation for engineering |

| Key Advantage | Tunable | Hardness and other properties can be engineered during manufacturing |

Need a cutting tool that outperforms the rest? KINTEK specializes in high-performance lab equipment and consumables, including CVD diamond solutions tailored for your specific application. Our expertise ensures you get the right grade of diamond for maximum tool life and efficiency. Contact our experts today to discuss how our engineered materials can enhance your project's performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- Is diamond coating worth it? Maximize Component Life and Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools