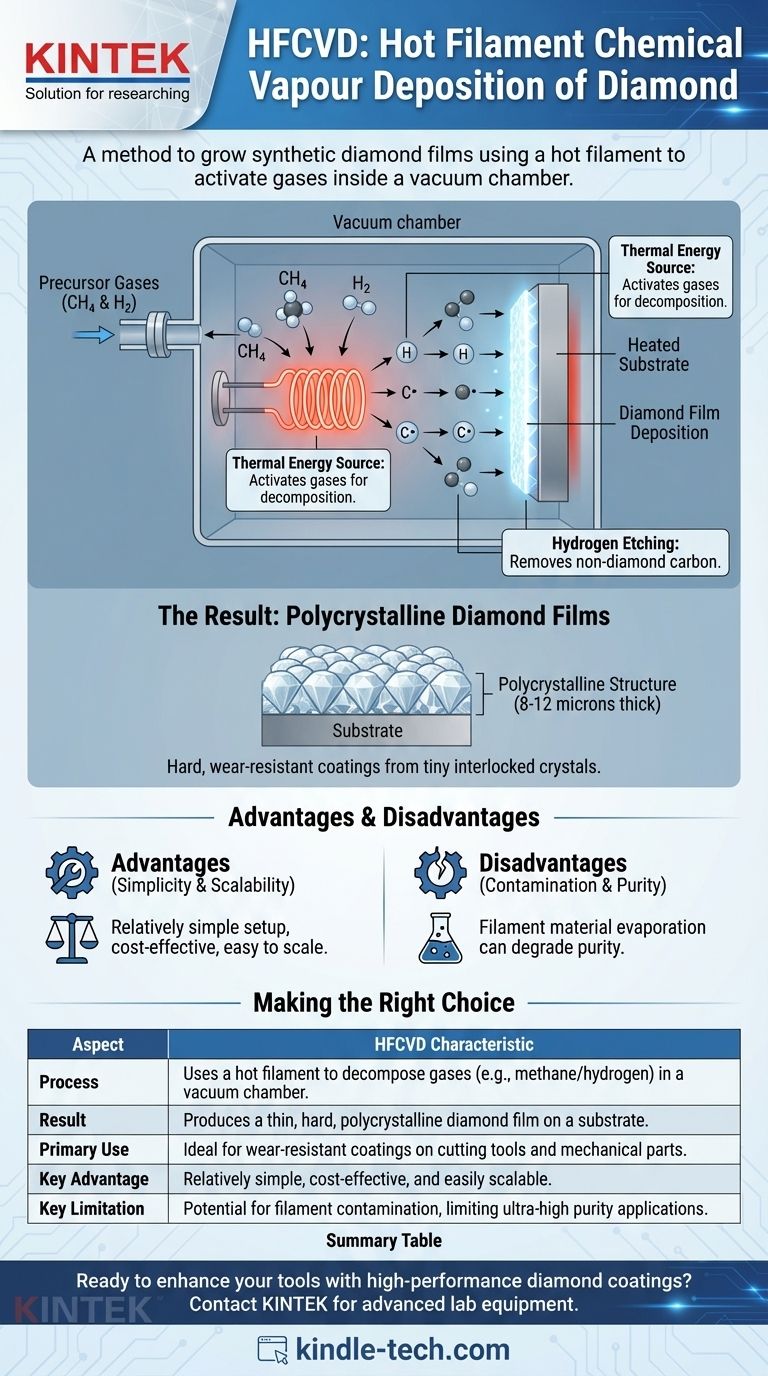

In short, Hot Filament Chemical Vapor Deposition (HFCVD) is a method used to grow synthetic diamond films onto a surface. It works by using an extremely hot wire, or filament, to break down simple gases like methane and hydrogen inside a vacuum chamber. The resulting carbon atoms then settle on a substrate, arranging themselves into a hard, pure diamond coating layer by layer.

The central principle of HFCVD is using a hot filament as the energy source to "activate" carbon-containing gas. This allows for the controlled decomposition of the gas and the subsequent formation of a high-quality diamond film on a nearby surface.

Deconstructing the HFCVD Process

To truly understand HFCVD, it's best to visualize it as a precise, multi-step recipe for creating diamond coatings. Each component plays a critical role in the final outcome.

The Vacuum Chamber Environment

The entire process takes place within a sealed chamber under a strong vacuum. This removes air and other contaminants that could interfere with the chemical reactions.

A low-pressure environment is essential for controlling the movement and reaction of the gas molecules, ensuring a stable and predictable growth process.

The Precursor Gases

A carefully controlled mixture of gases is injected into the chamber. This mixture almost always consists of a carbon source gas (typically methane, CH₄) and a much larger volume of hydrogen (H₂).

Methane provides the carbon atoms that will eventually form the diamond, while hydrogen plays a vital, more complex role in the process.

The Hot Filament: The "Engine" of the Process

This is the defining feature of HFCVD. A thin wire, usually made of tungsten or tantalum, is positioned near the substrate and heated electrically to extreme temperatures, often above 2000°C (3632°F).

This intense heat provides the thermal energy needed to break the chemical bonds of the gas molecules. The hydrogen molecules (H₂) split into highly reactive atomic hydrogen (H), and methane molecules (CH₄) break down into various carbon-containing radicals.

The Substrate and Deposition

The reactive carbon species then travel to a nearby heated substrate—the object being coated. Here, they bond to the surface and to each other, forming the characteristic crystal structure of diamond.

Simultaneously, the atomic hydrogen actively etches away any non-diamond carbon (like graphite) that might try to form. This "cleaning" action is crucial for ensuring the deposited film is pure, high-quality diamond.

The Result: Polycrystalline Diamond Films

The HFCVD process does not create a single, large gemstone. Instead, it produces a thin but incredibly robust film.

What is a Polycrystalline Film?

The diamond film grows from many individual nucleation points on the substrate simultaneously. These tiny crystals expand until they meet, forming a continuous film composed of many small, interlocked diamond grains. This is known as a polycrystalline structure.

Key Characteristics and Applications

The resulting films are exceptionally hard, chemically inert, and have low friction. Film thickness is precisely controlled, often in the range of 8 to 12 microns for applications like tooling.

Because of this hardness, HFCVD diamond is most commonly used to coat cutting tools, drills, and wear-resistant parts, dramatically increasing their lifespan and performance.

Understanding the Trade-offs

Like any engineering process, HFCVD has distinct advantages and disadvantages that make it suitable for some applications but not others.

Advantage: Simplicity and Scalability

Compared to other diamond CVD methods (like microwave plasma), the HFCVD setup is relatively simple, inexpensive, and easy to scale up for coating large areas or batches of parts.

Disadvantage: Filament Contamination

The primary drawback is the hot filament itself. Over time, the filament material can evaporate and become incorporated into the growing diamond film as an impurity. This can slightly degrade the film's thermal or optical properties.

Disadvantage: Purity Limitations

Due to the potential for filament contamination, HFCVD is often less suitable for applications requiring the absolute highest purity, such as in high-performance electronics or optical windows.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on your end goal. HFCVD is a powerful tool when used for the right purpose.

- If your primary focus is creating hard, wear-resistant coatings: HFCVD is an excellent, industry-proven, and cost-effective choice for improving the durability of mechanical components and tools.

- If your primary focus is high-purity electronic or optical components: HFCVD is generally not the first choice; you should investigate alternative methods like Microwave Plasma CVD (MPCVD) that offer higher purity.

- If your primary focus is accessible R&D and material science: HFCVD provides a reliable and relatively low-cost platform for studying the fundamentals of diamond growth.

Ultimately, HFCVD stands as a workhorse technology, enabling the practical application of diamond's extraordinary properties onto everyday engineering materials.

Summary Table:

| Aspect | HFCVD Characteristic |

|---|---|

| Process | Uses a hot filament to decompose gases (e.g., methane/hydrogen) in a vacuum chamber. |

| Result | Produces a thin, hard, polycrystalline diamond film on a substrate. |

| Primary Use | Ideal for wear-resistant coatings on cutting tools and mechanical parts. |

| Key Advantage | Relatively simple, cost-effective, and easily scalable. |

| Key Limitation | Potential for filament contamination, limiting ultra-high purity applications. |

Ready to enhance your tools with high-performance diamond coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for diamond film deposition. Whether you're in R&D or manufacturing, our expertise can help you leverage HFCVD technology to achieve superior wear resistance and extend the life of your components.

Contact us today using the form below to discuss how our solutions can meet your specific laboratory and coating needs.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies