The fundamental importance of the injection moulding machine lies in its unparalleled ability to produce highly complex and consistent plastic parts at immense scale. It is the core technology that transforms raw plastic pellets into finished, functional products with a combination of speed, precision, and cost-effectiveness that is unmatched for high-volume manufacturing.

The true value of an injection moulding machine is not just in making plastic parts; it is the engine that enables modern mass production. It uniquely balances geometric complexity with extreme repeatability, making it the foundational process for countless products we use every day.

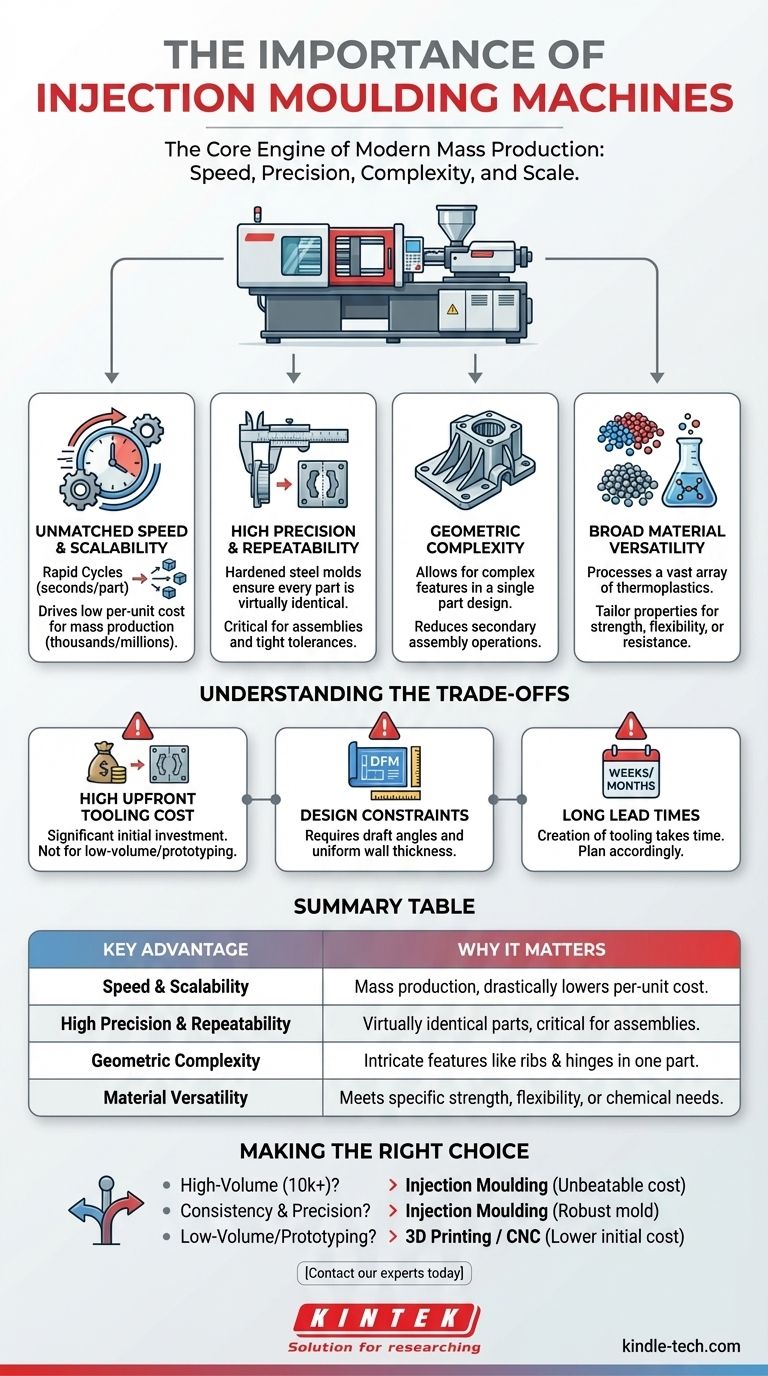

The Core Pillars of Injection Moulding's Dominance

To understand why this machine is so critical, you must grasp the unique advantages it brings together. No other single process combines these four elements as effectively for mass production.

Unmatched Speed and Scalability

The injection moulding process is incredibly fast. A complete production cycle—injecting plastic, cooling the part, and ejecting it—can take mere seconds.

This rapid cycle time means a single machine can produce thousands or even millions of parts in a continuous run. This immense scalability is what drives the per-unit cost down dramatically, making mass-produced goods affordable.

High Precision and Repeatability

The heart of the process is a hardened steel mold, or tooling. This mold is a precision-machined negative of the final part.

Because the plastic is injected into this same rigid cavity every single time, each part produced is virtually identical to the last. This ensures high repeatability and adherence to tight dimensional tolerances, which is critical for parts that need to fit together perfectly, like in electronics or automotive assemblies.

Freedom in Geometric Complexity

Injection moulding allows for the creation of incredibly intricate part geometries that would be difficult or cost-prohibitive to produce with other methods.

Designers can incorporate complex features like ribs for strength, bosses for screw attachments, and living hinges for flexible components directly into the part design. This integration of features reduces the need for secondary assembly operations, saving time and cost.

Broad Material Versatility

Injection moulding machines can process a vast array of thermoplastic polymers. This allows engineers to select a material with the exact properties required for the final product.

Whether a part needs to be rigid and strong, soft and flexible, transparent, or resistant to heat and chemicals, there is likely a compatible polymer available. This material flexibility makes the process suitable for an enormous range of applications.

Understanding the Trade-offs

Despite its dominance, injection moulding is not the solution for every project. Understanding its limitations is key to using it effectively.

The High Upfront Cost of Tooling

The primary drawback is the significant initial investment in creating the steel mold. Tooling is complex to design and manufacture, often costing tens of thousands to hundreds of thousands of dollars.

This high upfront cost makes injection moulding economically unviable for prototyping or low-volume production runs.

Design Constraints and Requirements

While it allows for complexity, the process has strict design rules. Parts must be designed with draft angles so they can be ejected from the mold without damage.

Maintaining a uniform wall thickness is also crucial to prevent defects like warping or sink marks. These design-for-manufacturing (DFM) principles require expertise and can constrain the initial design concept.

Long Lead Times for Initial Production

The creation of the tool itself takes time, typically ranging from several weeks to many months. This means you cannot go from a final design to a mass-produced part overnight.

This long lead time must be factored into any product development schedule.

Making the Right Choice for Your Production Needs

Your production goal is the ultimate guide to whether an injection moulding machine is the right tool for the job.

- If your primary focus is high-volume production (10,000+ units): The machine's low per-part cost, driven by speed and automation, is an unbeatable economic advantage.

- If your primary focus is part consistency and precision: The robust nature of the steel mold ensures that every part meets specifications, making it ideal for assemblies and quality-critical products.

- If your primary focus is prototyping or low-volume runs: The high tooling cost and long lead times make other methods like 3D printing or CNC machining far more practical and cost-effective.

Ultimately, the injection moulding machine has earned its place as a cornerstone of manufacturing by providing a reliable and scalable path from raw material to a precise, finished product.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| Speed & Scalability | Cycle times of seconds enable mass production, drastically lowering per-unit cost. |

| High Precision & Repeatability | Hardened steel molds ensure every part is virtually identical, critical for assemblies. |

| Geometric Complexity | Allows for intricate features like ribs, bosses, and living hinges in a single part. |

| Material Versatility | Processes a wide range of thermoplastics to meet specific strength, flexibility, or chemical resistance needs. |

Ready to scale your production with precision?

At KINTEK, we specialize in providing the lab equipment and consumables that support advanced manufacturing processes like injection moulding. Whether you are optimizing your material selection or ensuring quality control, our solutions help you achieve consistent, high-quality results.

Contact our experts today to discuss how KINTEK can equip your laboratory for manufacturing excellence.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the difference between two-high and three high rolling mills? Boost Your Metal Rolling Efficiency

- What is pyrolysis of rubber? Transform Waste Tires into Oil, Carbon & Gas

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What is the difference between extruded and co extruded? A Guide to Single vs. Multi-Layer Plastic Profiles

- What are the two common types of injection molding processes? Thermoplastic vs. Thermoset Explained

- What is the process of extrusion blowing? A Guide to Efficient Hollow Plastic Part Production

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- What is a two-roll differential speed mill? Achieve Superior Polymer Mixing & Dispersion