The lifespan of a vacuum tube is not a fixed number; it is a variable determined entirely by its operating conditions and type. For an amplifier used for practice a few times a week at modest volumes, power tubes can last several years, while preamp tubes may last five to ten years or even longer. However, for a heavily used touring amplifier, this lifespan can be shortened to a year or less.

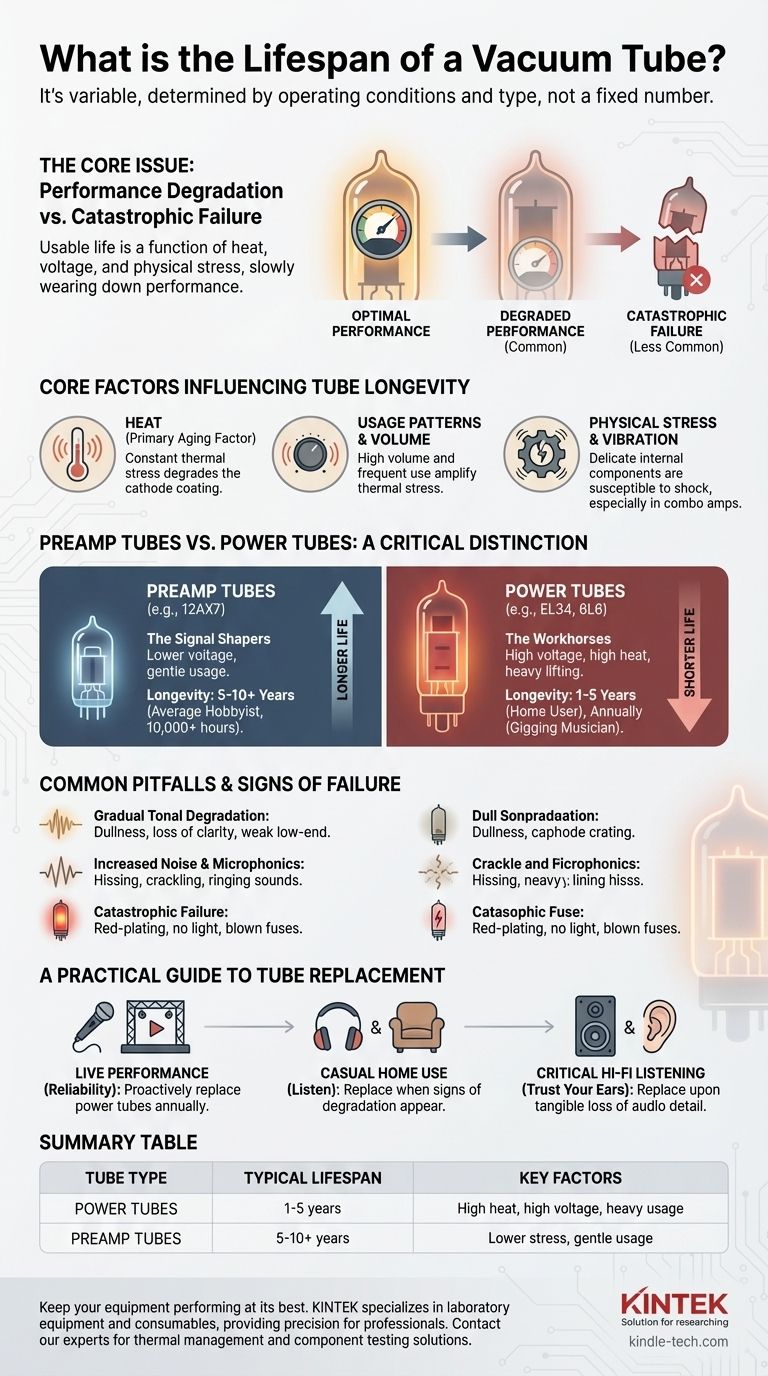

The core issue is not when a tube will catastrophically fail, but when its performance degrades. A tube's usable life is a function of heat, voltage, and physical stress, which slowly wear down its ability to perform as intended.

The Core Factors Influencing Tube Longevity

To understand a tube's lifespan, you must first understand the forces working against it. A vacuum tube is a delicate electromechanical device, and its life is a battle against heat and stress.

Heat: The Primary Aging Factor

A tube works by heating a cathode to emit electrons. This process, combined with the high voltages often applied to other elements inside the tube, generates significant heat.

This constant thermal stress is the primary cause of aging. Over time, it slowly degrades the cathode's coating, reducing its ability to emit electrons efficiently.

Usage Patterns and Volume

How often and how hard you run your equipment directly impacts heat generation. Pushing an amplifier to high volumes increases the electrical current and voltage running through the tubes.

This amplifies the thermal stress, accelerating the aging process. Conversely, infrequent use at low volumes is far gentler and will significantly extend a tube's life.

Physical Stress and Vibration

Vacuum tubes are built like old-fashioned light bulbs, with delicate internal components suspended by wires. They are highly susceptible to physical shock and vibration.

This is especially relevant for combo guitar amplifiers, where the tubes are housed in the same cabinet as the speaker. Constant vibration can cause internal parts to shift or break, leading to noise, microphonics (a ringing sound), or outright failure.

Preamp Tubes vs. Power Tubes: A Critical Distinction

Not all tubes in an amplifier are the same. Their function dictates their lifespan.

Power Tubes: The Workhorses

Power tubes, such as the EL34, 6L6, or KT88, do the heavy lifting. They handle high voltages and large currents to amplify the signal enough to drive a speaker.

Because they run much hotter and work harder, power tubes have a significantly shorter lifespan. A gigging musician might replace them annually, while a home user might get three to five years or more.

Preamp Tubes: The Signal Shapers

Preamp tubes, like the 12AX7 or ECC83, handle the small initial signal from your instrument or source. They operate at much lower voltages and currents.

Since they live a far less stressful life, preamp tubes last much longer than power tubes. It's not uncommon for them to function well for over 10,000 hours, which can translate to a decade or more of use for the average hobbyist.

Common Pitfalls and Signs of Failure

A tube rarely just stops working. Instead, it usually experiences a gradual decline that affects sound quality long before it fails completely.

Gradual Tonal Degradation

This is the most common end-of-life scenario. The sound may become dull, lose high-end clarity, or the low-end response might feel weak and "flabby." The tube still functions, but it has lost its optimal sonic character.

Increased Noise and Microphonics

A failing tube can introduce unwanted noise, such as hissing, crackling, or popping sounds. It may also become microphonic, picking up physical vibrations and translating them into an audible ringing through the speaker.

Catastrophic Failure

While less common, a tube can fail suddenly. This might manifest as "red-plating," where an internal plate glows bright red from excessive current—a condition that can damage the amplifier. Other signs include a tube that no longer lights up or one that causes a fuse to blow.

A Practical Guide to Tube Replacement

Your approach to tube maintenance should be guided by your specific use case and goals. There is no single correct schedule.

- If your primary focus is reliability for live performance: Proactively replace your power tubes annually and have a spare set of preamp tubes on hand.

- If your primary focus is casual home use: Do not replace tubes on a schedule. Instead, learn to listen for the signs of degradation—dull tone, lack of punch, or excess noise.

- If your primary focus is critical hi-fi listening: Trust your ears. When you notice a tangible loss of audio detail, dynamics, or soundstage, it is time to consider replacement.

Ultimately, your ears are the best tool for judging a tube's health; they will tell you when a replacement is needed far more accurately than a calendar.

Summary Table:

| Tube Type | Typical Lifespan (Moderate Use) | Key Factors |

|---|---|---|

| Power Tubes (e.g., EL34, 6L6) | 1-5 years | High heat, high voltage, heavy usage |

| Preamp Tubes (e.g., 12AX7) | 5-10+ years | Lower stress, gentle usage |

Keep your equipment performing at its best. Whether you're a musician relying on your amp's tone or an audiophile seeking pristine sound, the right tools and knowledge are key. KINTEK specializes in laboratory equipment and consumables, providing the precision and reliability that professionals demand. If your work depends on precise thermal management or electronic component testing, our expertise can help. Contact our experts today to discuss how we can support your specific needs.

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the principle of a tube furnace? Master Controlled Heating for Precise Lab Results

- How do high-temperature reaction furnaces control HEA synthesis? Master Carbothermal Shock for Nanoparticles

- What role does a continuous flow quartz tube reactor play in XAS? Ensure Precise Catalyst Pre-treatment

- What is thermal processing of semiconductors? Master the Heat that Builds Modern Chips

- What is RTA rapid temperature annealing? Achieve Precise Material Processing in Seconds

- How do you clean an alumina tube furnace? Extend Tube Life with Proper Maintenance

- What are the advantages of using an electric heating furnace with a quartz tube for liquid bismuth corrosion control?

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance