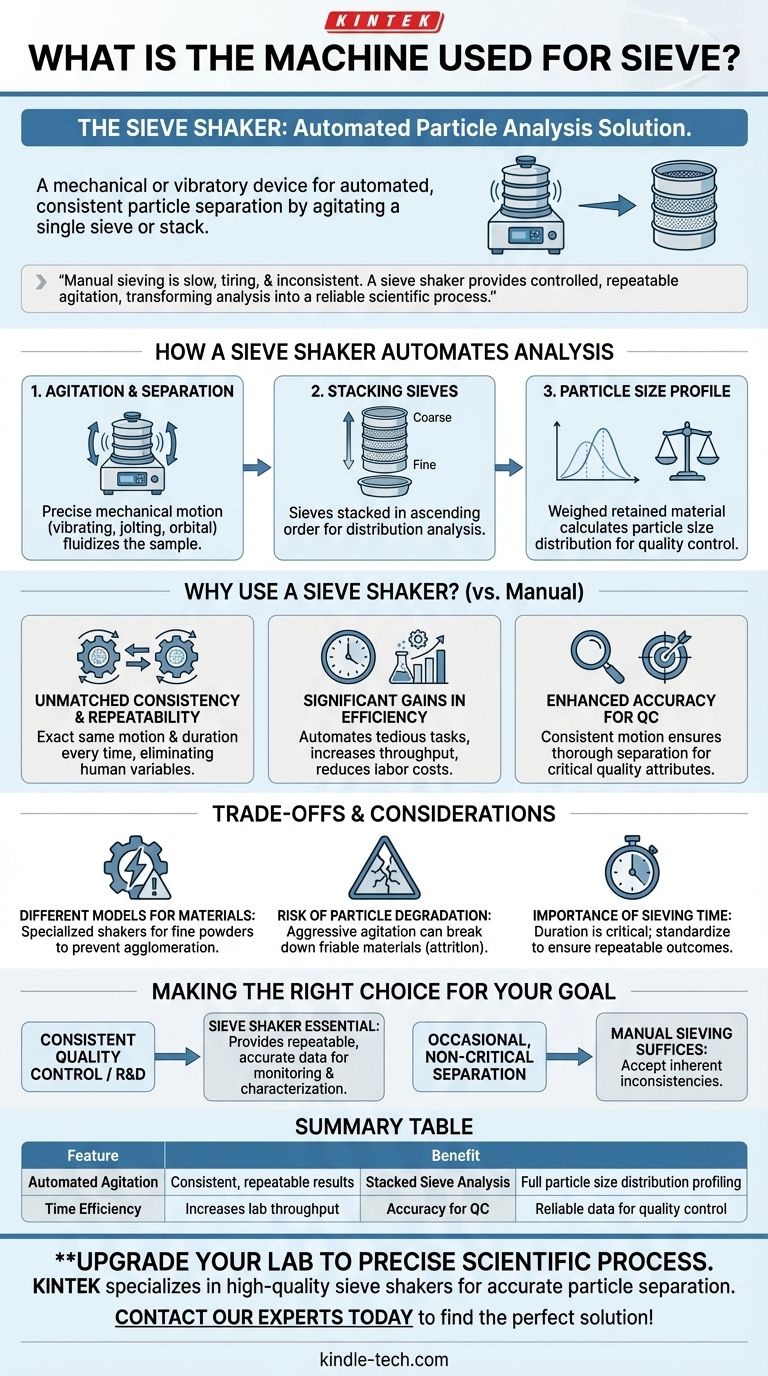

The machine used with sieves is called a sieve shaker, sometimes referred to as a mechanical or vibratory shaker. Its purpose is to automate the process of particle separation by agitating a single sieve or a stack of sieves with varying mesh sizes. This ensures that particles are efficiently and consistently sorted by size for analysis.

Manual hand sieving is often slow, tiring, and produces inconsistent results. A sieve shaker solves this by providing controlled, repeatable agitation, transforming particle analysis into a reliable and efficient scientific process for quality control and research.

How a Sieve Shaker Automates Particle Analysis

A sieve shaker replaces the variability of manual shaking with a precisely controlled motion. This mechanical consistency is the key to achieving accurate and repeatable particle size analysis.

The Basic Principle: Agitation and Separation

The core function of a sieve shaker is to impart motion—often a combination of vibrating, jolting, or orbital movements—to the test sieves. This agitation fluidizes the material sample, allowing each particle the opportunity to pass through the sieve openings if it is small enough.

Stacking Sieves for Distribution Analysis

For a full analysis, sieves are stacked in ascending order of fineness, with the coarsest mesh at the top and the finest at the bottom. A solid collection pan is placed at the very bottom of the stack. The entire material sample is placed in the top sieve before the machine is activated.

The End Result: A Particle Size Profile

Once the shaking cycle is complete, the material retained on each sieve is weighed. This data is then used to calculate the particle size distribution of the sample, providing a clear profile of the different size fractions within the material. This is a critical metric for quality control in countless industries.

Why Use a Sieve Shaker Over Manual Sieving?

While manual sieving is possible, a mechanical sieve shaker offers definitive advantages that are essential for any professional application.

Unmatched Consistency and Repeatability

A machine provides the exact same motion for the exact same duration, every single time. This eliminates the human variables of operator strength and technique, ensuring that results from different tests can be compared reliably.

Significant Gains in Efficiency

A sieve shaker automates a tedious and labor-intensive task. It allows a technician to run a test while performing other duties, dramatically increasing laboratory throughput and reducing labor costs.

Enhanced Accuracy for Quality Control

The consistent and optimized motion of a sieve shaker ensures a more thorough separation of particles than is typically achievable by hand. This level of accuracy is non-negotiable for manufacturing environments where particle size is a critical quality attribute.

Understanding the Trade-offs and Considerations

While highly effective, a sieve shaker is a piece of scientific equipment that requires proper application to yield correct results.

Different Models for Different Materials

Specialized shakers, such as electromagnetic sieve shakers, are designed for extremely fine powders (as small as 5 microns). Using the wrong type of agitation can cause fine or electrostatically charged particles to clump together (agglomerate) rather than separate.

The Risk of Particle Degradation

Aggressive agitation can be a problem for friable or delicate materials. The mechanical action can break down the particles themselves, a phenomenon known as attrition, which will skew the results to show a finer distribution than is actually present.

The Importance of Sieving Time

The duration of the shaking cycle is a critical parameter. Insufficient time leads to incomplete separation, while excessive time may not improve results and could increase particle degradation. This variable must be standardized for your specific material to ensure repeatable outcomes.

Making the Right Choice for Your Goal

The decision to use a sieve shaker depends entirely on the required level of precision and repeatability for your work.

- If your primary focus is consistent quality control: A sieve shaker is essential for providing the repeatable, accurate data needed to monitor and validate production processes.

- If your primary focus is research and development: The ability to control variables like agitation time and intensity makes a sieve shaker a critical tool for characterizing new materials.

- If your primary focus is occasional, non-critical separation: Manual sieving can suffice for rough estimations, but you must accept its inherent inconsistencies and lack of repeatability.

Ultimately, integrating a sieve shaker elevates particle analysis from a manual chore into a controlled, scientific process.

Summary Table:

| Feature | Benefit |

|---|---|

| Automated Agitation | Replaces manual shaking for consistent, repeatable results |

| Stacked Sieve Analysis | Enables full particle size distribution profiling |

| Time Efficiency | Frees up technician time and increases lab throughput |

| Accuracy for QC | Provides reliable data critical for manufacturing quality control |

Upgrade your lab's particle analysis from a manual chore to a precise scientific process. KINTEK specializes in high-quality lab equipment, including reliable sieve shakers designed for accurate and efficient particle separation. Whether you're in quality control or R&D, our solutions ensure the consistent results you need. Contact our experts today to find the perfect sieve shaker for your specific materials and application!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- How do industrial-grade sieving systems facilitate the adjustment of chromium powder combustion performance?

- What are the two applications of sieving? From Baking to Construction, Master Material Separation

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- Why is a standard sieving system used during the processing of TiB2-TiN-WC mixed powders? Ensure Material Consistency

- Which types of diameter or size can be determined using sieve shaker method for the given granular sample? A Guide to the 38 µm to 4 mm Range

- How does a constant temperature shaker improve adsorption kinetics? Enhance Tetracycline Removal Accuracy

- What are the different types of sieve shakers? Match the Shaker to Your Material for Accurate Particle Analysis

- What is a sieve shaker used in a laboratory? Automate Particle Size Analysis for Accurate Results