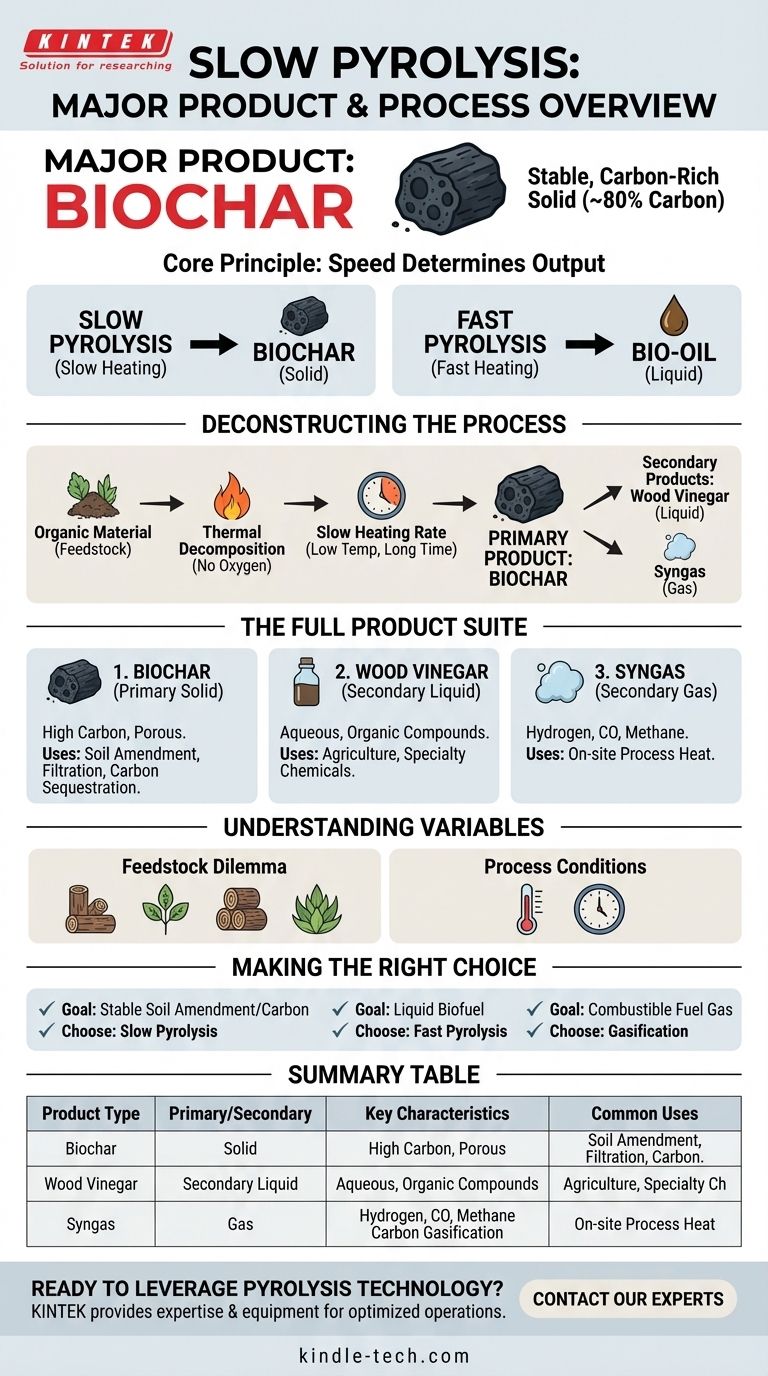

The major product of slow pyrolysis is biochar, a stable, carbon-rich solid also known as charcoal or biocoal. This process, often called carbonization, intentionally uses slow heating rates in an oxygen-free environment to maximize the conversion of organic material into this solid form, which typically consists of around 80% carbon.

The core principle of pyrolysis is that the speed of the process determines the primary output. Slow pyrolysis is deliberately engineered to maximize the yield of the solid product (biochar), while fast pyrolysis is optimized to produce a liquid product (bio-oil).

Deconstructing the Pyrolysis Process

To understand why slow pyrolysis yields biochar, we must first understand the fundamental variables that control the outcome of any pyrolysis reaction.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of organic materials at elevated temperatures in the absence of oxygen. Instead of burning, the material breaks down into its constituent components, producing three distinct types of products: a solid, a liquid, and a gas.

The Critical Role of Heating Rate

The key variable that distinguishes different pyrolysis methods is the heating rate. How quickly the organic material (feedstock) is heated directly influences which of the three product types is maximized.

- Slow Heating: Low temperatures and long process times favor the formation of a stable, solid carbon structure.

- Fast Heating: High temperatures and extremely short process times "crack" the organic vapors into smaller molecules that are rapidly cooled and condensed into a liquid.

Slow Pyrolysis: Maximizing the Solid Product

Slow pyrolysis uses low heating rates over an extended period. This process is specifically designed to prioritize the production of biochar. The slower decomposition allows carbon atoms to arrange into stable aromatic structures, leaving behind a solid residue. The liquids and gases are considered secondary products.

Fast Pyrolysis: A Contrast in Purpose

In direct contrast, fast pyrolysis uses extremely high heating rates. The goal here is to break down the biomass and immediately quench the resulting vapors, condensing them into a liquid known as bio-oil or pyrolysis oil. In this process, char and gas are the secondary byproducts.

The Full Product Suite of Slow Pyrolysis

While biochar is the main goal, slow pyrolysis is a decomposition process that inevitably creates liquids and gases as well.

The Primary Product: Biochar

Biochar is the carbon-rich solid that remains after pyrolysis. Its high carbon content and porous structure make it valuable for several applications, including agricultural soil amendment, water filtration, and long-term carbon sequestration.

The Secondary Liquid Product: Wood Vinegar

Some of the volatile compounds released during slow pyrolysis condense into a liquid. This aqueous liquid, often called wood vinegar or tar, is a complex mixture of organic compounds. It can be refined for use in agriculture or as a source for specialty chemicals.

The Gaseous Byproduct: Syngas

Non-condensable gases, collectively known as synthesis gas or syngas, are also produced. This gas mixture contains hydrogen, carbon monoxide, and methane. In most pyrolysis plants, this syngas is captured and burned to provide the heat required for the process, making the system more energy-efficient.

Understanding the Trade-offs and Variables

The output of any pyrolysis unit is not fixed. The exact yield and quality of biochar, liquids, and gas are highly dependent on several factors.

The Feedstock Dilemma

The type of organic material being processed has a significant impact on the outcome. Woody biomass, agricultural waste, and manure all have different chemical compositions, which will result in different product yields and biochar characteristics.

Process Conditions Matter

Temperature and residence time are the two main levers an operator can pull to fine-tune the output. Even within slow pyrolysis, slight adjustments can shift the ratio of char, liquid, and gas produced, allowing for optimization based on the specific feedstock and desired product quality.

Making the Right Choice for Your Goal

Selecting the correct thermal conversion technology depends entirely on your desired end product.

- If your primary focus is creating a stable soil amendment or sequestering carbon: Slow pyrolysis is the correct process, as its main output is biochar.

- If your primary focus is producing a liquid biofuel for energy or refining: Fast pyrolysis is the superior method, as it is optimized for bio-oil production.

- If your primary focus is generating a combustible fuel gas for power generation: Gasification, a related process that uses a small amount of oxygen, is the most direct route for maximizing syngas yield.

Understanding the relationship between process conditions and final products is the key to leveraging thermal conversion technology effectively.

Summary Table:

| Product Type | Primary/Secondary | Key Characteristics | Common Uses |

|---|---|---|---|

| Biochar (Solid) | Primary | ~80% carbon, stable, porous | Soil amendment, carbon sequestration, filtration |

| Wood Vinegar (Liquid) | Secondary | Aqueous liquid, organic compounds | Agriculture, specialty chemicals |

| Syngas (Gas) | Secondary | Hydrogen, carbon monoxide, methane | On-site heat for the pyrolysis process |

Ready to leverage pyrolysis technology for your specific needs?

Whether your goal is to produce high-quality biochar for agricultural or environmental applications, KINTEK has the expertise and equipment to help. We specialize in providing reliable lab equipment and consumables for advanced thermal conversion processes.

Contact our experts today to discuss how our solutions can optimize your pyrolysis operations and help you achieve your product yield targets.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan